Rtl & rtl-fcb series, Imperial installation specifications, Chart 3 – DE-STA-CO Ferguson Rite-Torq Torque Limiters (Overload Clutches) Type RT, RTM, RTL, RTL-FCB User Manual

Page 10

10

RTL & RTL-FCB Series

NOTE: Steps 1-8 apply to RTL-FCB type clutch.

1. RTL-FCB (shaft/shaft) torque limiters are furnished with a flexible coupling to tolerate

moderate angular and/or parallel misalignment. The maximum acceptable angular

misalignment is 0.5 degree and maximum acceptable parallel offset is 0.005”.

2. Determine angular alignment by checking the gap between the coupling and the torque

limiter with a ruler, caliper or gauge. The gap should be even all around but not exceed 0.5

degree, as previously mentioned (see Figure 3).

3. Determine parallel alignment by use of a straight edge or indicator. A straight edge should

lie evenly on both members but not to exceed .005” (see Figure 4).

4. Fit key into shaft keyways and hand apply thin coat of anti-seize compound.

5. NOTE: Torque limiter and coupling with maximum bores have shallow keyways.

6. Separate torque limiter & coupling hub by pulling or prying apart (FCB Series only).

7. Mount the torque limiter to the driving or driven shaft on the slow speed side of the reducer

and secure it by tightening the two set screws. The use of Loctite

242 or similar adhesive

on the set screws is recommended.

8. Slide the coupling hub onto the shaft to be connected. Align the studs on the torque limiter

and hub with the holes in the elastomer bushings (Figure 6) in the opposing members and

slide the hub towards the torque limiter until the members are seated together. Align the

shafts per the above tolerances and tighten the coupling hub to the shaft using the furnished

standard QD type bushing.

NOTE: Steps 9-10 apply to basic RTL-type clutch.

9. Assemble the sprocket, pulley, etc. to the torque limiter using the tapped holes provided by

Industrial Motion Control.

CAUTION: SCREW THREAD DEPTH MUST NOT EXCEED THAT LISTED IN CHART 3.

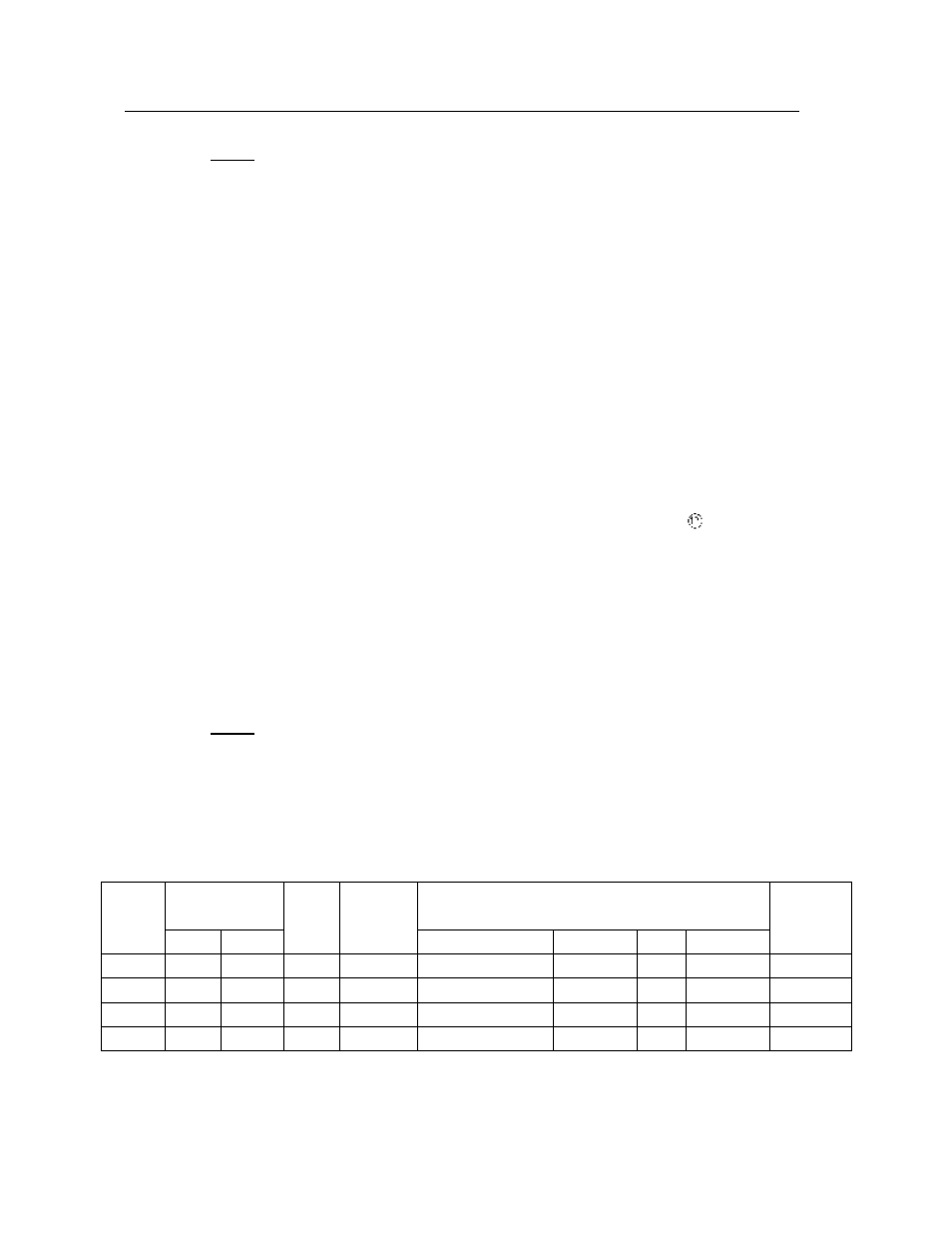

IMPERIAL INSTALLATION SPECIFICATIONS

Trip Torque

(IN-LBS)

Max.

Actuator

Plate

Sprocket Mounting

Max.

Model

MIN.

MAX

RPM

Travel

Thread*

B.C.

NO.

Pilot Dia.

Bore

5

100

500

1800

.073 IN.

¼-20X5/8 dp.

3.750 IN.

4

2.500

1.250 IN.

20

400

2000

1200

.092 IN.

¼-20X3/4 dp.

4.875 IN.

6

3.375

1.750 IN.

60

1200

6000

900

.110 IN.

5/16-18X3/4 dp.

6.000 IN.

6

4.000

2.250 IN.

120

2400

12000

600

.146 IN.

3/8-16X1 dp.

7.000 IN.

6

4.750

2.750 IN.

CHART 3