Proper position, Setting position of piston – Carlon Expansion Joints User Manual

Page 3

w w w . c a r l o n . c o m

Add 30°F to

temperature

change for direct

sunlight exposure.

Solvent weld

Mid-point

Piston opening

Pipe strap

should be anchored

tightly to barrel

Pipe strap

mounted loosely

to allow movement

Solvent weld

Length

of Run

(Feet)

Inches of Expansion Allowance Needed

for Temperature Changes of:

60°F

80°F

100°F

120°F

140°F

25

5

/

8

3

/

4

1

1

1

/

4

1

3

/

8

50

1

1

/

4

1

5

/

8

2

2

3

/

8

2

3

/

4

75

1

3

/

4

2

3

/

8

3

3

1

/

2

4

1

/

8

100

2

3

/

8

3

1

/

8

4

4

3

/

4

5

1

/

2

125

3

4

5

6

7

150

3

5

/

8

4

3

/

4

6

7

1

/

8

8

1

/

4

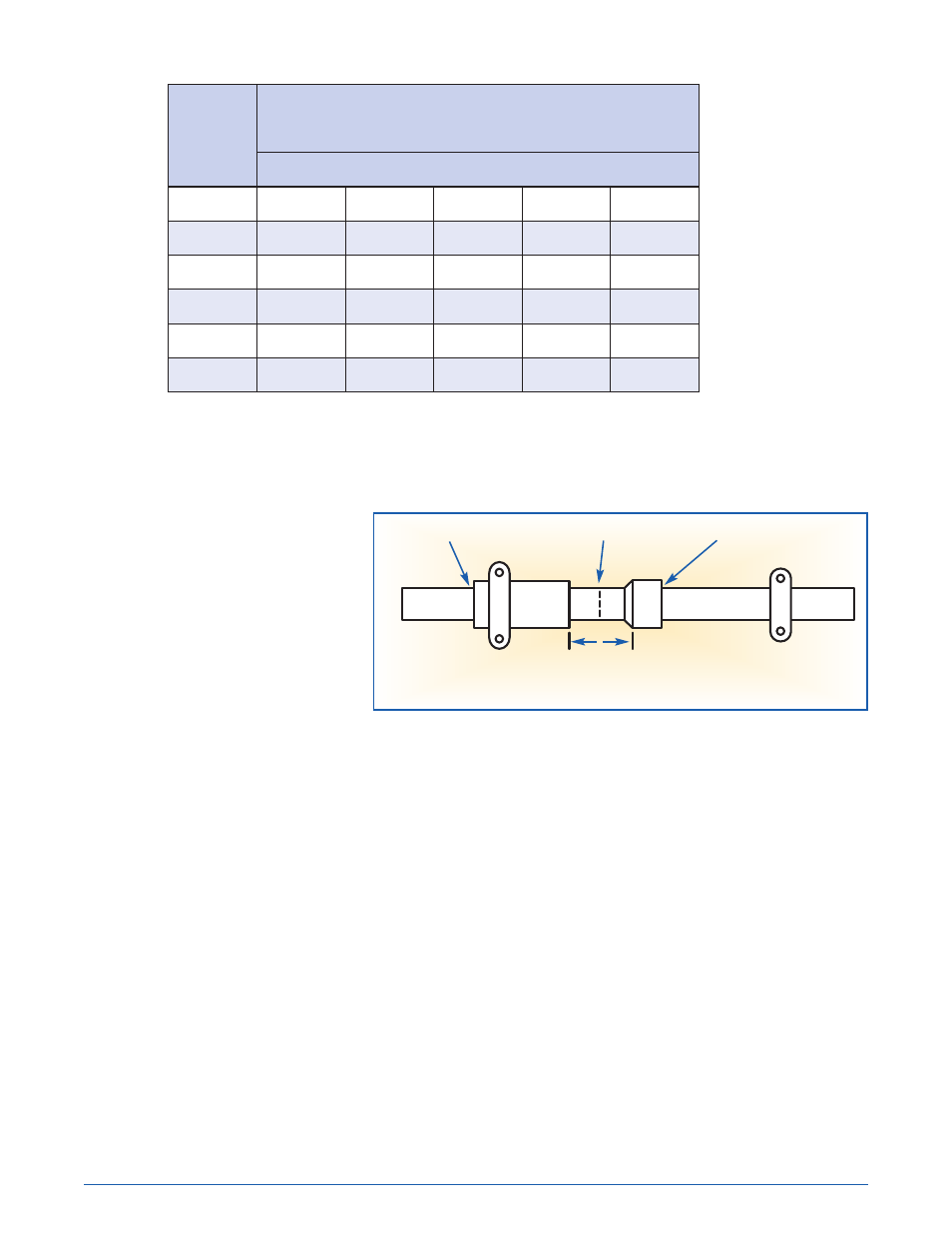

Proper Position

Expansion fittings are usually installed in a

horizontal position. However, if they must

be put in a vertical application, the open

end should be securely fastened in the

down position. The expansion fitting must

be installed close to the top of the run

with the barrel pointing down, so that

rain water does not enter into the opening.

The lower end of the conduit run should

be secured at the bottom. This will result

in an upward movement due to the length

change caused by temperature variations.

Setting Position of Piston

If an expansion fitting was installed completely closed with

the piston bottomed on a cool day, there would be no travel

available when the conduit warmed up and expanded. If it

was installed in a maximum open position on a hot day, the

expansion fitting would pull apart when cooled. Thus, “setting”

the expansion fitting is very important.

In addition to the proper number and sizes of expansion fittings

chosen, they must also be installed so they can accommodate

the expected length change. This requires proper “setting” of

the expansion fitting. Most will be installed at a temperature

halfway between maximum and minimum; for example,

installation at 65°F with an anticipated maximum temperature

of 125°F and a minimum of 5°F. In this case, the expansion

fitting would be installed or set with the inner piston halfway

out. Expansion fittings are marked with a mid-point. If it was

a colder day, for example 35°F with the same expected

temperature change range, the inner piston would be set with

1/4 of its maximum travel out. If the temperature was hot

(95°F), it would be set with the inner piston only 3/4 way out.

Gross Automation (877) 268-3700 · www.carlonsales.com · [email protected]