Carlon Rigid Nonmetallic Conduit Properties, Wirefill and Weights - Low Res User Manual

Weight comparison, Rigid nonmetallic conduit, Thermal

Rigid Nonmetallic Conduit

www.carlonsales.com

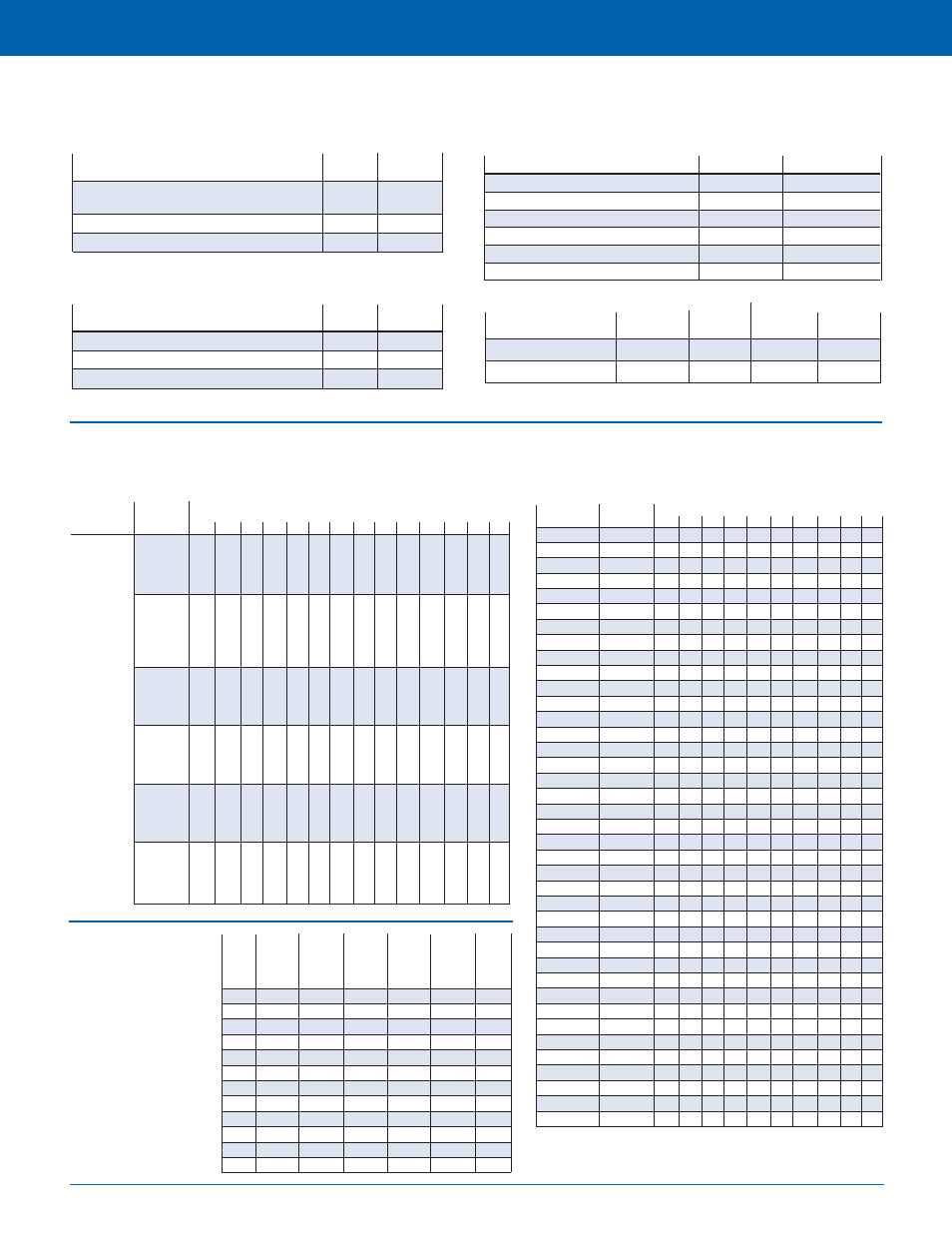

Typical Properties of Conduit Raw Material Compound

Wire Fill

Conductor

Type

Size

Trade Size

Letters

AWG, MCM

1

/

2

3

/

4

1 1

1

/

4

1

1

/

2

2

2

1

/

2

3

3

1

/

2

4

4

1

/

4

5

6

8

14

13

24

39

69

94 154

12

10

18

29

51

79 114 164

10

6

11

18

32

44

73

194 160

8

3

5

9

19

22

36

51

71 106 136

6

1

4

6

11

15

26

37

57

76

98

125 154

4

1

2

4

7

9

16

22

35

47

60

75

94 137 236

3

1

1

3

6

8

13

19

29

39

51

64

90 116 201

2

1

1

3

5

7

11

16

25

33

43

54

67

97 169

1

1

1

3

5

9

12

18

25

32

49

59

72 125

1/0

1

1

3

4

7

10

15

21

27

33

42

61 105

2/0

1

1

2

3

6

8

13

17

22

28

35

51

88

3/0

1

1

1

3

5

7

11

14

18

23

29

42

73

4/0

1

1

1

2

4

6

9

12

15

19

24

35

61

250

1

1

1

3

4

7

10

12

16

20

28

49

300

1

1

1

3

4

6

8

11

13

17

24

42

350

1

1

1

2

3

5

7

9

12

15

21

37

400

1

1

1

3

5

6

8

10

13

19

33

500

1

1

1

2

4

5

7

9

11

16

27

600

1

1

1

1

3

4

5

7

9

13

22

700

1

1

1

3

4

5

6

8

11

19

750

1

1

1

2

3

4

6

7

11

19

6

1

3

5

9

13

21

30

47

63

81

102 128 185 320

600

1

1

1

1

3

4

5

7

9

13

22

700

1

1

1

3

4

5

6

7

11

19

750

1

1

1

2

3

4

6

7

10

18

Thermal

ASTM

Typical

Test

Values

Co-efficient of Thermal Expansion-inch/inch/°F

D696

3.38 x 10

-5

(properties @ 73.4°F)

Heat Distortion °F at 264 psi

D648

160°F

Thermal Conductivity BTU (hr.) (ft.) (°F/in.)

N/A

1.3

Electrical

ASTM

Typical

Test

Values

Dielectrical Strength volts/mil

D149

1100

Dielectric Constant 60 CPS @ 30°C

D150

4.00

Power Factor 60 CPS @ 30°C

D150

1.93

Mechanical

ASTM Test

Typical Values

Specific Gravity

D792

1.43 - 1.6

Tensile Strength (psi) @ 73.4°F

D638

5,000-6,500

Izod Impact ft lbs./in. of notch

D256

0.65 - 1.5

Flexural Strength (psi)

D790

12,500

Compressive Strength (psi)

D695

9,000

Hardness (Durometer D)

D2240

85

Impedance

(Volts lost per ampere per 100 feet)

3

л 90%

80%

1

л 90%

80%

P.F.

P.F.

P.F.

P.F.

Steel Conduit

.0118

.0123

.0136

.0142

Schedule 40

®

.0105

.0106

.0121

.0122

Using 250 KCmil Cu. conductor. comparable values for other conductor sizes.

THWN

THHN

FEP

(14 thru 2)

FEPB

(14 thru 8)

PFA

(14 thru 4/0)

PFAH

(14 thru 4/0)

Z

(14 thru 4/0)

XHHW

(4 thru

500MCM)

XHHW

Maximum number of conductors in Schedule 80 PVC conduit

(Based on Table 1, Chapter 9 of the NEC)

Conductor Size

Trade Size

AWG, MCM

1

/

2

3

/

4

1 1

1

/

4

1

1

/

2

2

2

1

/

2

3

4

5

# 14

THW

4

8

13

24

34

57

82

128

THHN

10

19

33

58

81

135 194

0

12

THW

3

6

11

20

28

47

67

105 183

THHN

8

14

24

43

60

100 144

0

10

THW

3

5

9

16

22

37

54

85

148

THHN

5

9

15

27

38

64

92

143

8

THW

1

2

4

8

11

19

28

44

77 121

THHN

1

4

7

13

18

31

45

70

123 195

6

THW

1

1

3

6

8

14

20

32

56

88

THHN

1

3

5

9

13

22

32

50

88 140

4

THW

0

1

2

4

6

10

15

24

42

66

THHN

1

1

3

6

8

13

20

31

54

86

3

THW

0

1

1

4

5

9

13

20

36

57

THHN

1

1

2

5

7

11

17

26

46

73

2

THW

0

1

1

3

4

8

11

17

31

49

THHN

1

1

1

4

5

9

14

22

38

61

1

THW

0

1

1

1

3

5

8

13

22

35

THHN

0

1

1

3

4

7

10

16

28

45

0

THW

0

0

1

1

2

4

7

11

19

30

THHN

0

1

1

2

3

6

8

13

24

38

00

THW

0

0

1

1

1

4

6

9

16

26

THHN

0

1

1

1

3

5

7

11

20

32

000

THW

0

0

1

1

1

3

5

8

14

22

THHN

0

0

1

1

2

4

6

9

16

26

0000

THW

0

0

1

1

1

3

4

6

11

18

THHN

0

0

1

1

1

3

5

8

14

22

250

THW

0

0

0

1

1

1

3

5

9

14

THHN

0

0

0

1

1

2

4

6

11

18

300

ThW

0

0

0

1

1

1

3

4

8

13

THHN

0

0

0

1

1

1

3

5

9

15

350

THW

0

0

0

1

1

1

2

4

7

11

THHN

0

0

0

1

1

1

3

4

8

13

400

THW

0

0

0

0

1

1

1

3

6

10

THHN

0

0

0

1

1

1

2

4

7

12

500

THW

0

0

0

0

1

1

1

3

5

8

THHN

0

0

0

0

1

1

1

3

6

10

600

THW

0

0

0

0

0

1

1

1

4

7

THHN

0

0

0

0

1

1

1

3

5

8

700

THW

0

0

0

0

0

1

1

1

3

6

Carlon

Carlon

Inter-

Schedule 40

®

Schedule 80

®

Electrical

mediate

Rigid

Rigid

Rigid

Metallic

Metal

Metal

Nom.

Nonmetallic Nonmetallic

Tubing

Conduit

Conduit

Size

Conduit

Conduit

Aluminum

(EMT)

(IMC)

(RMC)

1

/

2

18

22

27

30

57

79

3

/

4

23

29

36

46

78

105

1

35

43

53

66

112

153

1

1

/

4

48

60

70

96

114

201

1

1

/

2

57

72

86

112

176

246

2

76

100

116

142

230

334

2

1

/

2

125

153

183

230

393

527

3

164

212

239

270

483

690

3

1

/

2

198

288

350

561

831

4

234

310

340

400

625

982

5

317

431

465

Not Made

Not Made

1344

6

412

592

612

Not Made

Not Made

1770

Weight

Comparison

Carlon Schedule 40

®

rigid nonmetallic

conduit compared to

other rigid conduit in

pounds per 100 feet

(approx.)

Maximum number of conductors in Schedule 40 PVC conduit

(Based on Table 1, Chapter 9 of the NEC)

24

Gross Automation (877) 268-3700 · www.carlonsales.com · [email protected]