Carlon Carflex Installation and Code Information - Low Res User Manual

Technical data, Carflex fittings installation instructions, Carflex liquidtight conduit technical information

www.carlonsales.com

8

Technical Data

Carflex Fittings Installation Instructions

LT43C-CAR, LT43F thru J, LT20C-CAR, LT20F thru J.

1. Cut the end of the Carflex conduit or Carflex

®

X-Flex

™

tubing square.

2. Install compression nut and sealing gland ring over the

end of the conduit or tubing.

3. Insert the ferrule end of the fitting into the conduit using

a clockwise twisting action.

4. Screw fitting body into compression nut.

5. When installation is completed, use a wrench,

tighten compression nut one-quarter (1/4) turn past

hand-tight. Do not over tighten fitting.

*To prevent damage to conductors, conduit and

fittings, do not twist Carflex during installation.

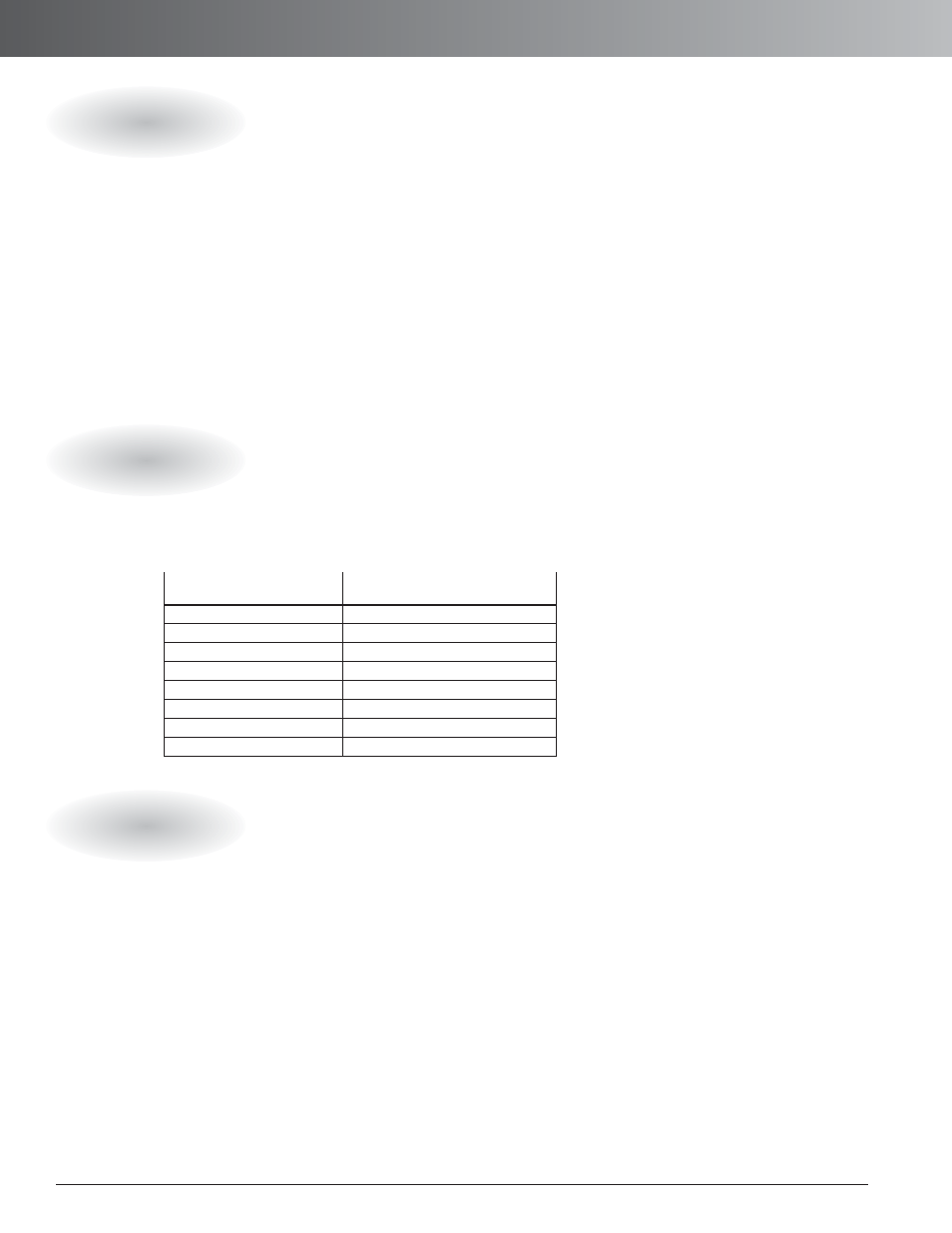

Carflex Liquidtight Conduit Technical Information

1. There shall be no more than the equivalent of four (4) quarter (90°) bends (360° total)

between pull points, conduit bodies, and boxes.

2. The radius of the curve of the center of the conduit or tubing shall not be less than

that shown in the table below:

UL Listed for use as indicated in Article 356 of the

National Electrical Code

• Cellular Metal Floor Raceways, Connections to

Cabinets & Wall Outlets

• Class I, Div. 2, Hazardous Location

• Class II, Div. 1, Hazardous Location

• Class III, Div. 1, Hazardous Location

• Computer Room Raised Floor

• Concealed Locations

• Intrinsically Safe Systems

• Lighting Fixtures, Connection to Electric Discharge

Fixture

• Nonmetallic Boxes

• RV Engine Generator

• Swimming Pool Pump Motor

• Tap Conductors (Fixture Whips)

• Underfloor Raceway, Connection to Cabinets &

Wall Outlets

• Wireway, Extensions from Wireways, Wiring

Methods

– Agricultural Buildings, Flexible Connections

– Electric Signs, 600 Volts, Nominal, or Less

– Electric Signs, Over 600 Volts

– Floating Buildings

– Marinas and Boatyards

– Service Entrance Conductors

• Wiring on Buildings, Outside Branch Circuits &

Feeders

• Direct Burial Applications

LT43D-New, LT43E-New, LT20D-New, LT20E-New.

1. Cut the end of the Carflex conduit or Carflex

®

X-Flex

™

tubing square.

2. Install compression nut over the end of the conduit or

tubing.

3. Insert the ferrule end of the fitting into the conduit using

a clockwise twisting action. (Be sure conduit

is fully inserted to the bottom of the fitting shoulder).

4. Screw compression nut onto fitting body.

5. Use a wrench, and tighten compression nut one (1) full

turn past hand-tight. Do not over tighten fitting.

*To prevent damage to conductors, conduit and

fittings, do not twist Carflex during installation.

SIZE OF CONDUIT

RADIUS TO CENTER OF CONDUIT

OR TUBING

OR TUBING

Inches

Metric Desgr.

Inches

(mm)

3

/

8

(14)

4

(101.6)

1

/

2

(16)

4

(101.6)

3

/

4

(21)

4

1

/

2

(114.3)

1

(27)

5

3

/

4

(146.0)

1

1

/

4

(35)

7

1

/

4

(184.1)

1

1

/

2

(41)

8

1

/

4

(209.5)

2

(53)

9

1

/

2

(241.3)

Gross Automation (877) 268-3700 · www.carlonsales.com · [email protected]