Bray 6P P_P Series User Manual

Page 5

Bray Series 6P

Operation and Maintenance Manual

5

INPUT SIGNAL

PRESSURE

SUPPLY

OUT 2

OUT 1

2

1

6

3

4

15

7

8

9

10

11

12

13

14

5

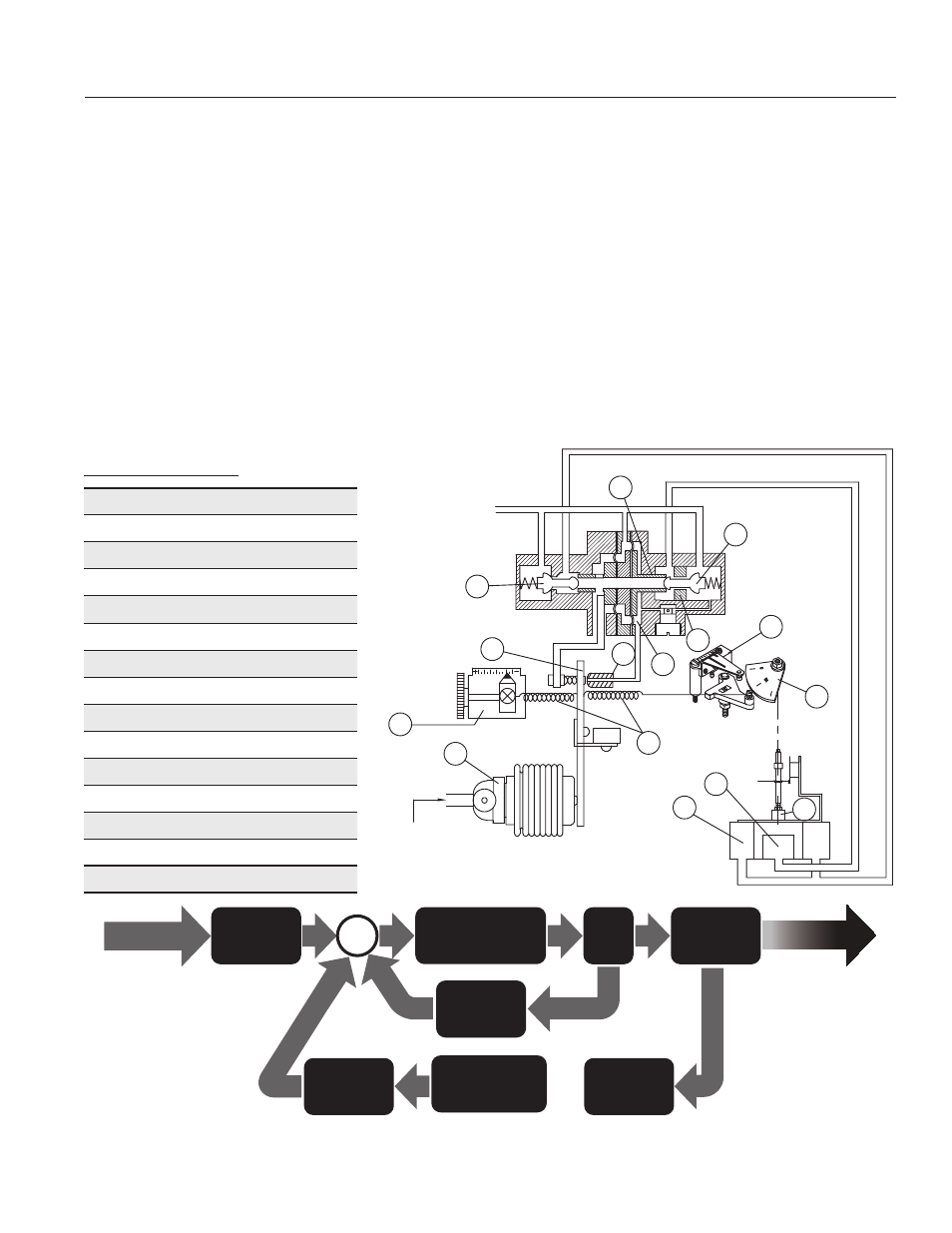

Operation Logic

• When signal input pressure increases, the bellows

(11) pushes the flapper (13), the gap between the

nozzle (5) and the flapper (13) increases, which

causes pressure in the upper spool chamber (4) to

exhaust. This causes the spool (1) to shift right.

• As the spool (1) moves right, it pushes the poppet

(2) off its seat (3), and air pressure is supplied to

the center actuator chamber (9).

• At the same time, the spool (1) causes the left

poppet (14) to seat and vent the outer chambers

(10).

• As the actuator’s inner pressure increases, the

actuator stem (8) rotates.

• When the signal input pressure decreases, the

spool (1) moves to the left reversing the action,

lifting the left poppet (14) and supplying pressure

to the outer actuator chambers (10) and venting

the inner actuator chamber (9).

Bray Series 6P

1. Spool

2. Right Poppet

3. Seat

4. Spool Chamber

5. Nozzle

6. Span Adjustment

7. Cam

8. Actuator Stem

9. Inner Actuator Chamber

10. Outer Actuator Chamber

11. Bellows

12. Zero Adjustment

13. Flapper

14. Left Poppet

15. Feedback Springs

Input Signal

Bellows

Mechanism

Actuator

Pilot

Relay

Flapper & Nozzle

Mechanism

Stroke Output

Stabilizer

Spring

Communication

Mechanism

Feedback

Spring

Feedback

Lever

SERIES 6E FIGURE 1

Figure 1