Table 1 tightening torques for end cap screws – Bray Triad Series User Manual

Page 3

Installation and Maintenance Manual

Triad Series Ball Valves

Date: August 2011 / Page 3 of 7

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2011 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

the end cap and ball, inserted through the end cap and

ball will prevent the ball from turning as the stem gland

nut is lightened on the stem.

Material for the bore alignment tool should be made

from a material softer than 300 Series S.S. so that it

will not inadvertently scratch the valve end cap or ball.

Suggested materials: aluminum T6061. Acetal or other

suitable hard polymer/plastic material.)

Secure the tab washer with one ear bending up; Place

the handle (25) onto the stem, on top of the stem gland

nut (26A);

Secure the handle (25) with the stem lock nut (26).

3”-4”” VALVE ASSEMBLY PROCEDURES:

Put washer protector (11B), thrust washer (12) and stem

bearing (13) on valve stem (5) and slide the stem Into

the stem hole on valve body (1):

Slide the stem packing (14) onto the stem until it is seated

against the upper bottom of the stem hole;

Put packing protector (IlA), then packing gland sleeve

(15) onto the stem, on top of the stem packing;

Install packing gland (16) on top of the packing gland

sleeve, lightly tighten to secure packing gland with pack-

ing gland bolt (17).

Install stop housing (20), secure stop housing with hous-

ing bolts (21) hand tight. Install travel stop (22) and

snap ring (30):

lnstall one seat (4 ) and two body seals inside an end

cap (2), make sure the spherical curvature side of the

seat will face the ball;

Install the end cap (2) with cap screws (9) and tighten

screws to the values indicated in Table 1.

Turn the stem to the closed position (wrench flats on stem

perpendicular to pipeline);

Install the ball (3) inside the valve body. The stem flats

will fit into the slot on top of the ball;

Turn the stem so that the ball is in the open position (the

ball will not fall out of the valve);

Install the second seat (4) and two body seals inside the

remaining end cap (2), make sure the spherical curvature

side of the seat will face the ball;

Install the end cap (2) with cap screws (9) and tighten

screws to the values indicated in Table 1.

Cycle the valve slowly several times. By cycling slowly,

the seats will conform to the ball. A fast turning motion

initially may damage the seats before they have a chance

to form the proper seal:

Tighten the packing gland bolts (17) gradually until there

is no leakage through the packing. Over-tightening can

result in excess torque and accelerated wear.

Install handle (25) on to the valve stem and secure the

handle with handle bolt (27).

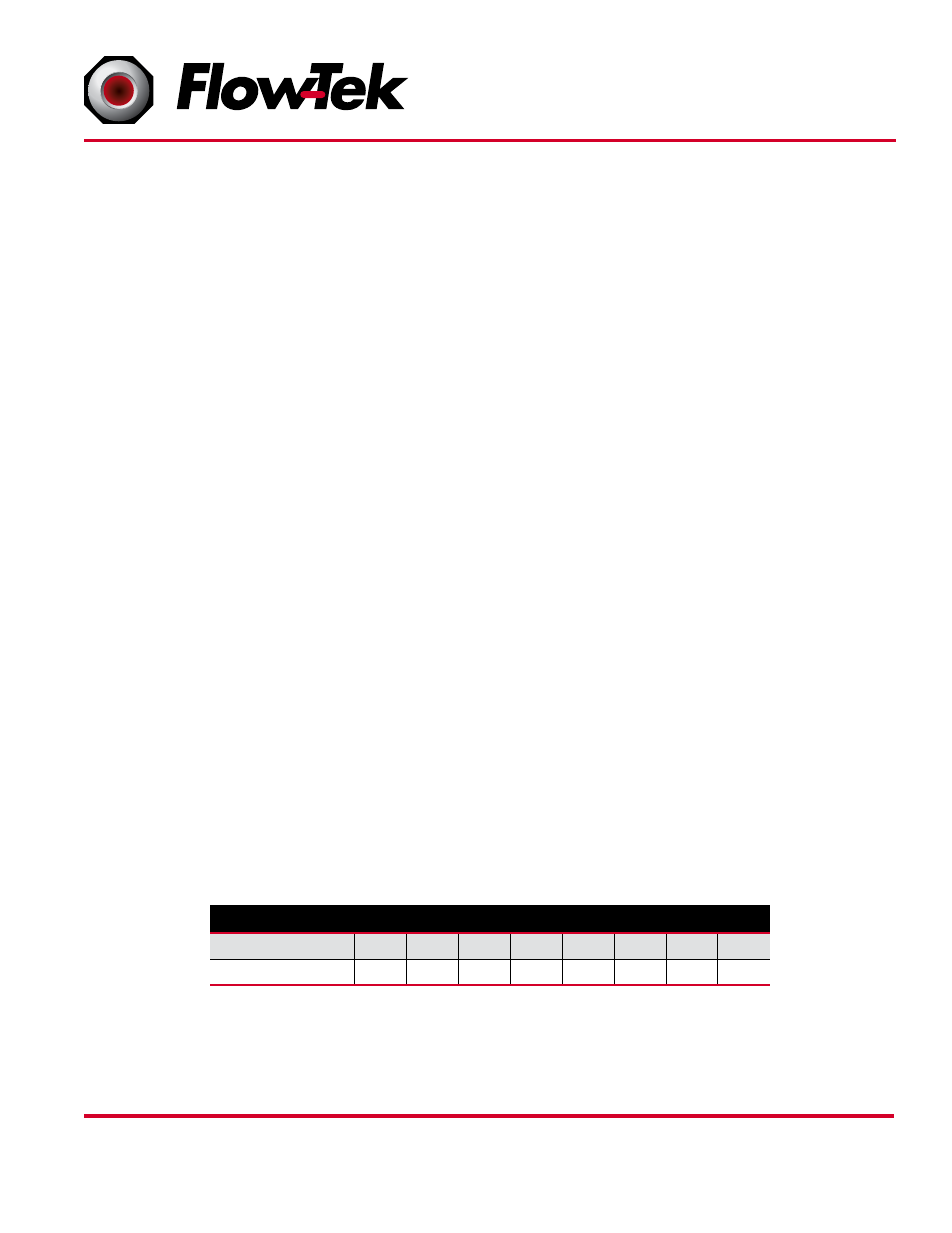

Table 1

Tightening torques for end cap screws

Valve Size

1/2”

3/4”

1”

1-1/4” 1-1/2”

2”

3”

4”

Bolt Torque (lb-in)

140

210

210

550

550

550

996

996