Bray MPF150_130_230_240 Series User Manual

Page 2

Installation and Maintenance Manual

MPF150/300, MPT230/240 Ball Valves

Date: April 2012 / Page 2 of 8

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2011 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

2. Disassembling and Cleaning the Valve

Ball valve can trap fluids in ball cavity when it is in

the closed position. If the valve has been used in

hazardous media, it must be decontaminated before

disassembly.

a. Relieve the line pressure.

b. Place valve in half-open position and flush the

line to remove any hazardous material from

valve cavity.

c. All persons involved in the removal and

disassembly of the valve should wear proper

protective clothing, such as face shield, glove,

apron, etc.

Delivery Condition and Storage

a. Valves are set to position 1;

b. Upon delivery, customer’s quality control must

check the package to make sure that the valves

are not damaged during the shipping process;

c. Valves must also be checked for loosening of

bolts due to shipment;

d. Valves should be stored indoors and in its

original package.

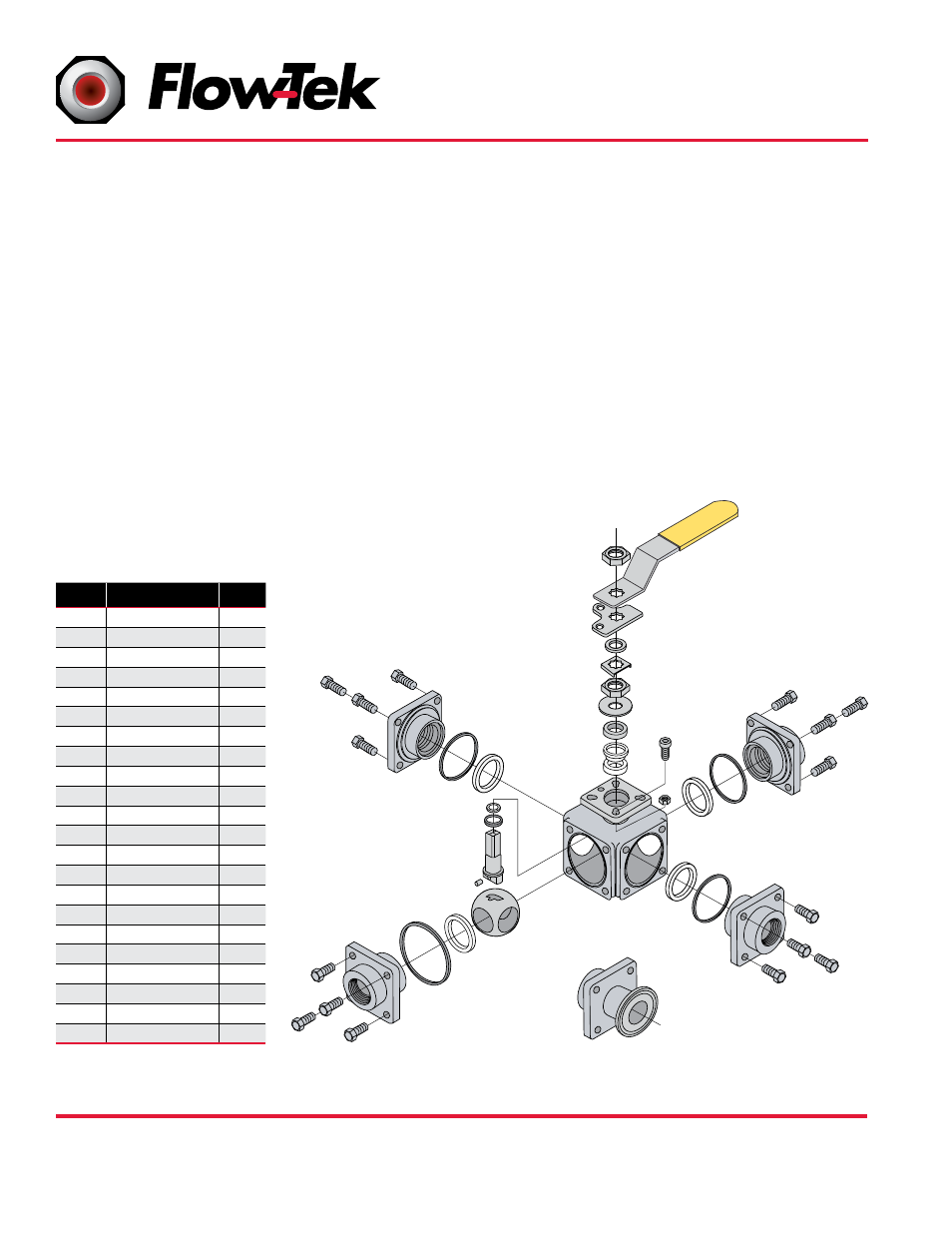

20

19

9

10

11

12

13

14

16

17

18

15

2

2

5

5

4

1

1

5

2

1

8

7

6

21

22

22

22

22

1

2

5

3

Item Name

Qty.

1

End Cap

4

2

Gasket**

4

3

Body

1

4

Ball*

1

5

Seat*

4

6

Stem*

1

7

Thrust Washer*

1

8

O-ring*

1

9

Stem Packing*

1

10

Gland

1

11

Belleville Washer

2

12

Stem Nut

1

13

Lock Saddle

1

14

Space Washer

1

15

Stop Plate

1

16

Handle Nut

1

17

Handle

1

18

Handle Sleeve

1

19

Stop Pin Bolt

1

20

Stop Pin Nut

1

21

Pin Insert

1

22

Bolt

16

Model MPT230

Threaded End

Connections

1/4” – 2” shown

Quick Clamp