Avcount2 overview – Atec StanhopeSeta-Avcount2 User Manual

Page 2

[email protected] // +44(0) 1932 575 000 // www.seta-analytics.com

AvCount2 Overview

Laser based particle analyser used for determining the particle concentration in Liquid fuels and oils. AvCount2 can be used

throughout distribution networks and in the laboratory, in fact anywhere that requires accurate determination of particle distribution

in a liquid sample. Whether checking the quality of fuel, filter systems or in service lubricants, AvCount2 provides fast and precise

results.

•

Checks on fuel distribution & filtering

•

Refinery processing quality

•

Corrosion & Rust in Pipes & Tanks

•

Contamination of in-service fluids

•

Ingress of airborne solids

•

Degraded & Damaged Hoses & Filters

•

Microbiological Growth

Laser Particle Count - The preferred test for sample diagnosis

Particle counts are used for a wide range of applications which

include fuels, hydraulic and lubricating oils, solvents, water-based

fluids, compressor fluids, refrigeration, turbines, transmissions

systems and many more. Results enable preventative maintenance

and assist system cleanliness.

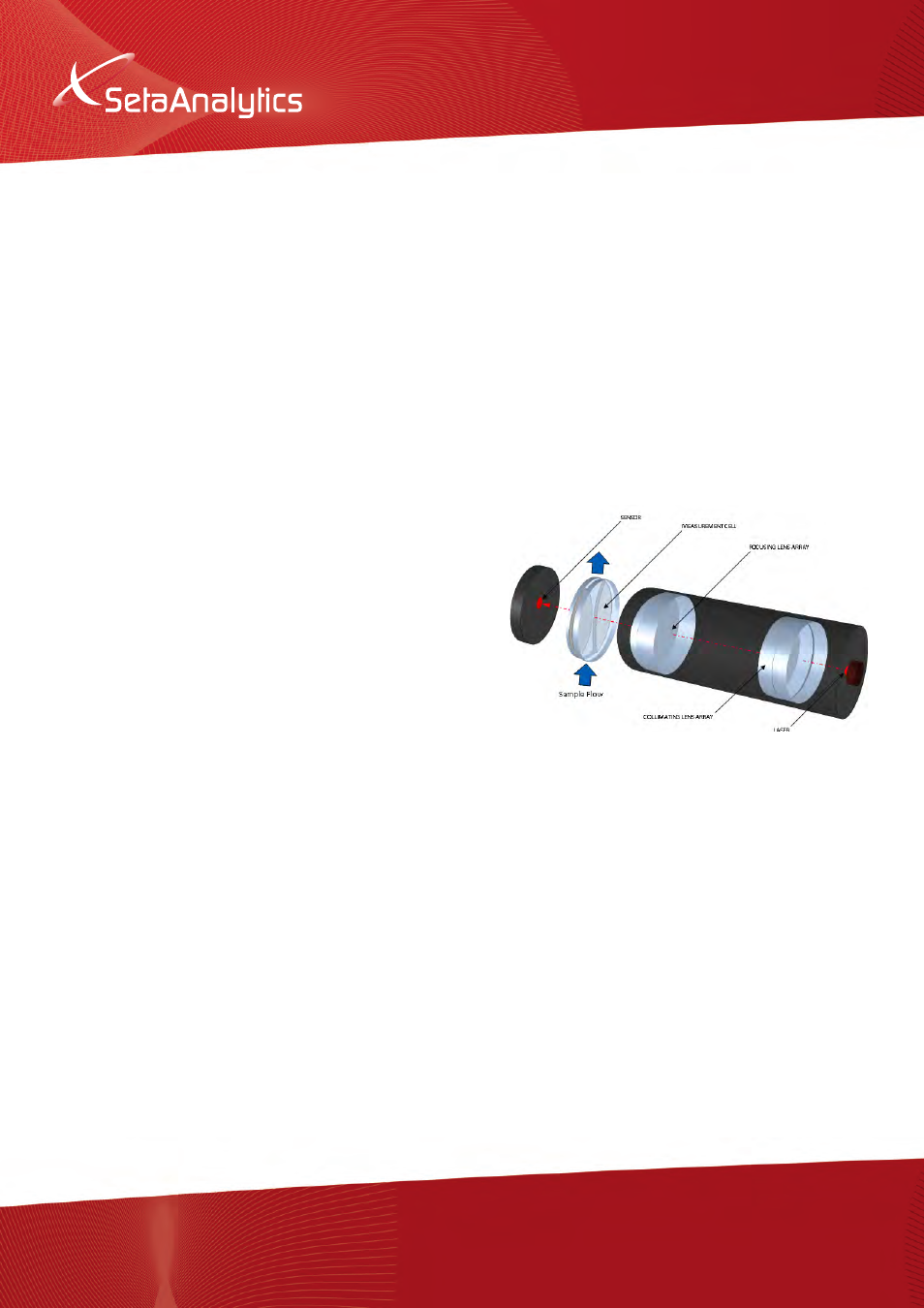

Laser particle counting uses the light emitted by a laser to illuminate

a cell through which the sample is passed. Particles present in the

sample cast a shadow onto the sensor within the cell, and as the

particle passes across the cell the voltage output of the sensor drops.

The voltage drop of the cell is proportional to the particle size and the

AvCount2 calculates the size of the particle based on this principle.

Particulate in Jet Fuels -

why is measurement so important?

Small particles of sediment present in jet fuel can agglomerate to form scales that may affect or wear nozzles and ducts within

the engine; in addition particulate contamination in the fuel may affect the quality of spray produced by the fuel injection system

reducing combustion efficiencies. It is therefore important to identify and remove particulate before the fuel is pumped onto an

aircraft.

Sediment contamination originates from tanks, pipelines, hoses, pumps, people, and even the environment. The most common

particulates that have potential to contaminate aviation fuels are rust, paint, metal, rubber, dust, and sand. For quality control

purposes sediment is classified by particle size.

For many years the Aviation industry has relied upon visual checks, known as ‘the clear and bright test’ to identify the presence

of particulate which is identified as a haze in the fuel sample. However the naked eye can only identify sediment particles larger

than 40 microns whereas the primary sediment particles that may be present in fuel are typically only 4-6 micron in size. The

development of high precision engine technology, together with greater emphasis on fuel efficiency, has lead to the demand for a

more precise method of determining the presence of particulate in fuels.

Laser particle counting is now a mandated test for Jet/Aviation fuel.