35 and 35dl – Atec Panametrics-35DL User Manual

Page 3

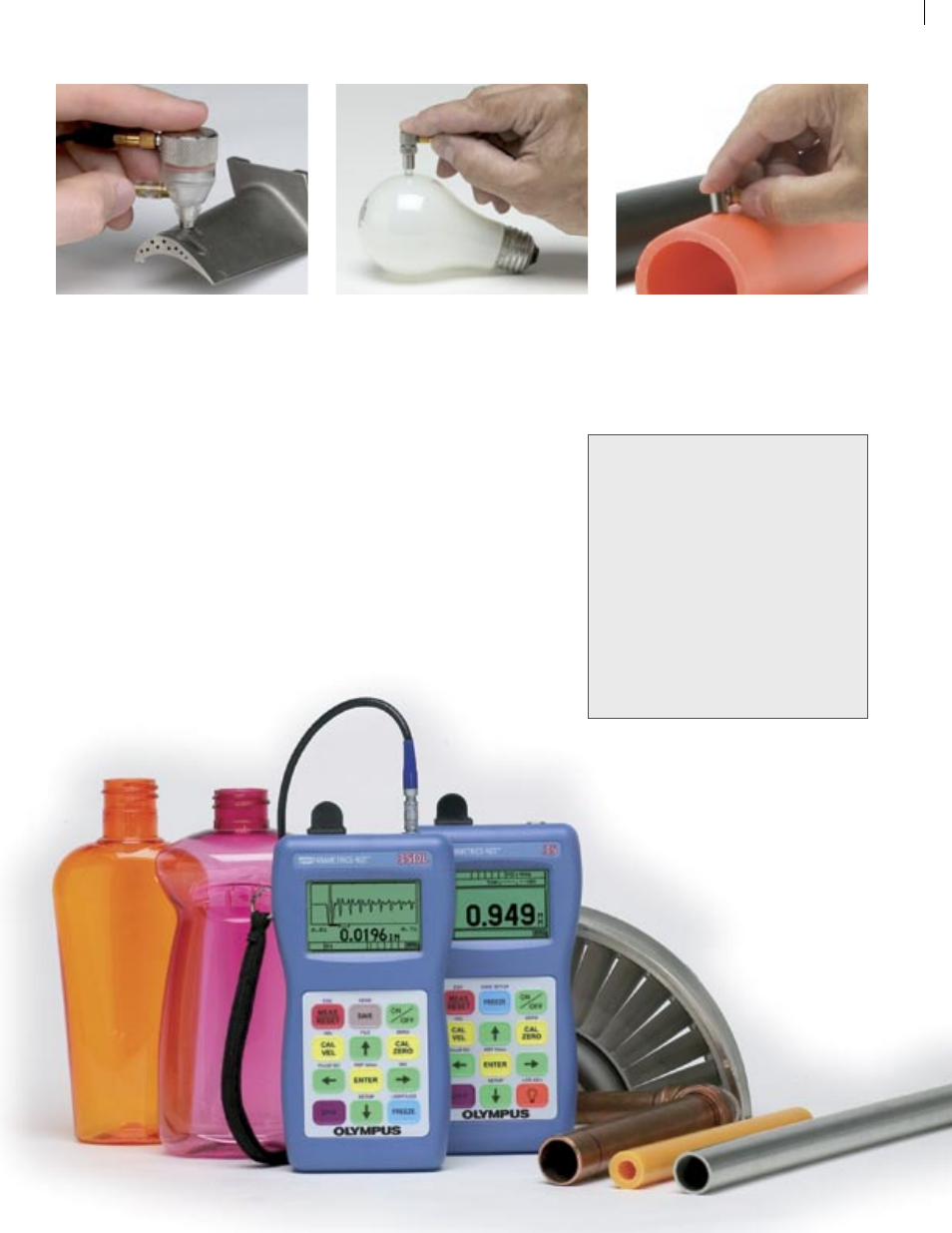

The 35 and 35DL can use transducers ranging from 2.25 to 30 MHz,

which means that these versatile gages can solve the majority of

thickness gaging applications, from very thin to very thick. In general,

transducers with higher frequencies and smaller diameters allow

measurements of thinner or curved parts and enhance the accuracy

of the measurement.

35 and 35DL

Models 35 and 35DL are used in the

majority of applications

Micrometers won’t work in this classic application.

Instead, the Model 35 with a M208 transducer makes

a thickness measurement up to a calibrated accuracy

of 0.001 mm (or 0.0001 inch) without breaking the

glass.

The Model 35 with a delay line transducer or immer-

sion bubbler makes accurate thickness measurements

on both convex and concave surfaces of turbine

blades.

Plastic or metal tubes and pipes of various diameters

can easily be measured ultrasonically with contact

type transducers. Small diameters may require immer-

sion type measurements.

920-103

From thin materials...

applications

- most materials, from thin to thick

- plastic bottles, tubes, pipes, sheets as

thin as 0.08 mm (or 0.003 inch)

- metal containers, steel coils, machined

parts as thin as 0.10 mm (or 0.004 inch)

- cylinder bores, turbine blades

- glass bulbs, bottles

- thin fiberglass, rubber, ceramics, and

composite materials

- curved areas or containers with

small radii

- resolution up to 0.001 mm or 0.0001”