Weld inspection solutions with phased array, Weld overlay, Epoch 1000 i multi-angle – Atec Panametrics-Olympus-Epoch-1000i User Manual

Page 8: True depth gates, Aws weld rating

8

www.olympus-ims.com

8

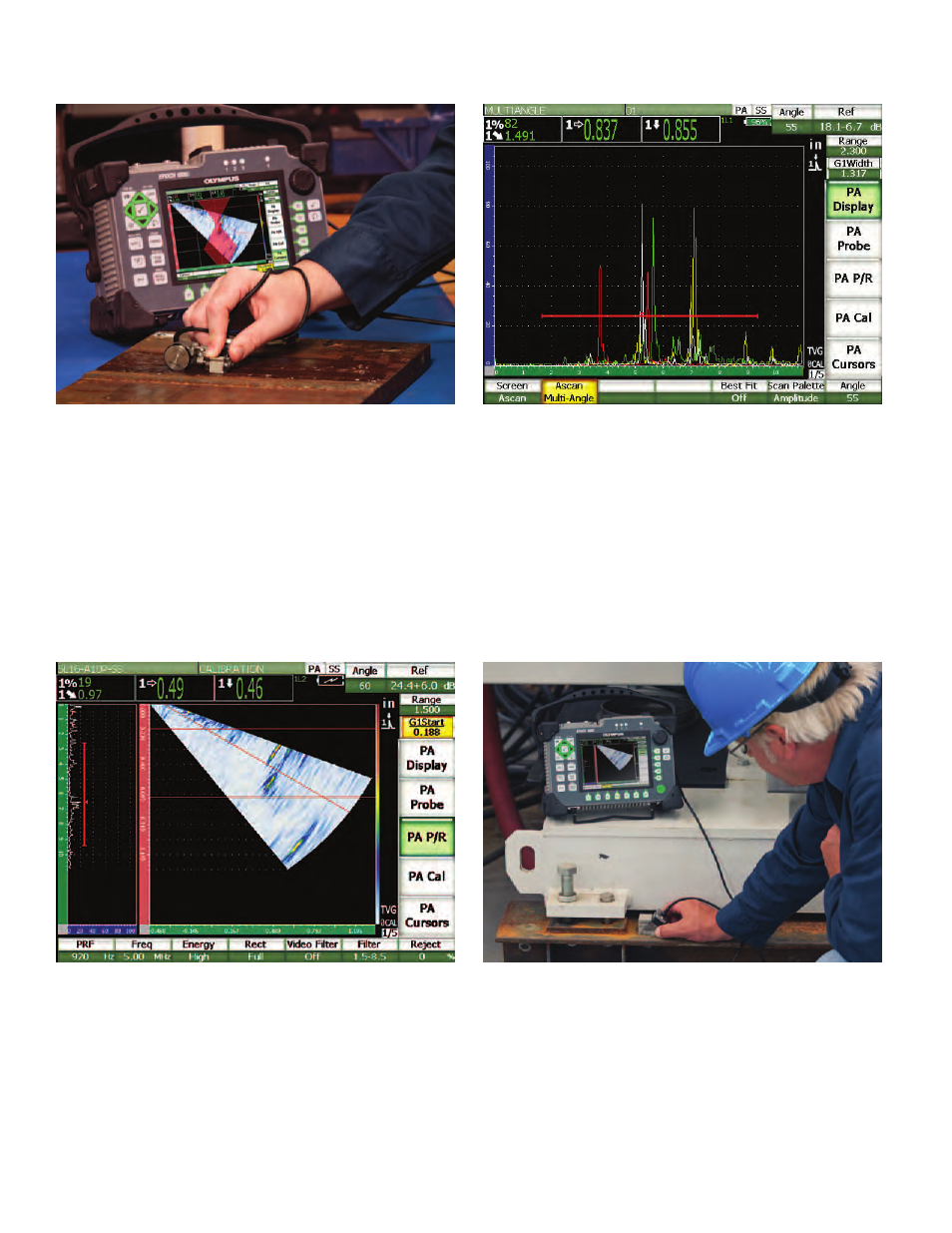

Weld Overlay

Weld Overlay is a standard inclusion on the EPOCH 1000i, pro‑

viding a visual reference of a weld profile on the S‑scan display.

This profile enables you to visualize the relative position of indi‑

cations in relation to the weld geometry.

A weld centerline cursor allows manual positioning of the overlay

on the S‑scan. The Weld Overlay enhances your ability to locate,

characterize, and size flaws within the component during inspec‑

tion, and improves reporting.

EPOCH 1000i Multi-Angle

The EPOCH 1000i phased array mode includes a standard feature

called Multi‑Angle. This feature enables you to designate any

three angles, or focal laws, available in the sector scan as “vis‑

ible” focal laws. The A‑scans from each of the three designated

angles are overlaid, one on top of the other in the A‑scan window,

enabling you to view all three A‑scans at the same time. Each

individual angle is color coded for ease of use. This feature is

perfect for inspectors using conventional sizing methods requiring

evaluation at 45°, 60°, and 70°.

Multi-Angle Phased Array Mode

Phased Array S-scan with Weld Overlay

Weld Inspection Solutions with Phased Array

AWS “D” Weld Rating displayed for 45° focal law

A-scan and S-scan view with True Depth Gates

True Depth Gates

Measurements gates can be displayed in True Depth mode on the

Sector Scan, thus enabling you to acquire measurements from a

constant depth area throughout the part, regardless of the focal

law selected. This is particularly helpful when using the encoded

C‑scan option, as it enables you to collect information for one

entire skip distance with a single gate position.

The True Depth gates display as horizontal lines on the S‑scan

only; the A‑scan view remains in Soundpath mode.

AWS Weld Rating

The EPOCH 1000i comes with an AWS D1.1/D1.5 weld rating

calculator. In conjunction with Olympus’ AWS‑rated phased

array transducer, this enables you to use imaging capabilities for

flaw detection while sizing flaws at 45°, 60°, and 70° using the

conventional A‑scan technique, and also view the D value for

onscreen weld rating of any selected A‑scan (focal law).