The raptor system: applications, Applications, Primary current injection testing – Atec EuroSMC-Raptor User Manual

Page 3

3

2

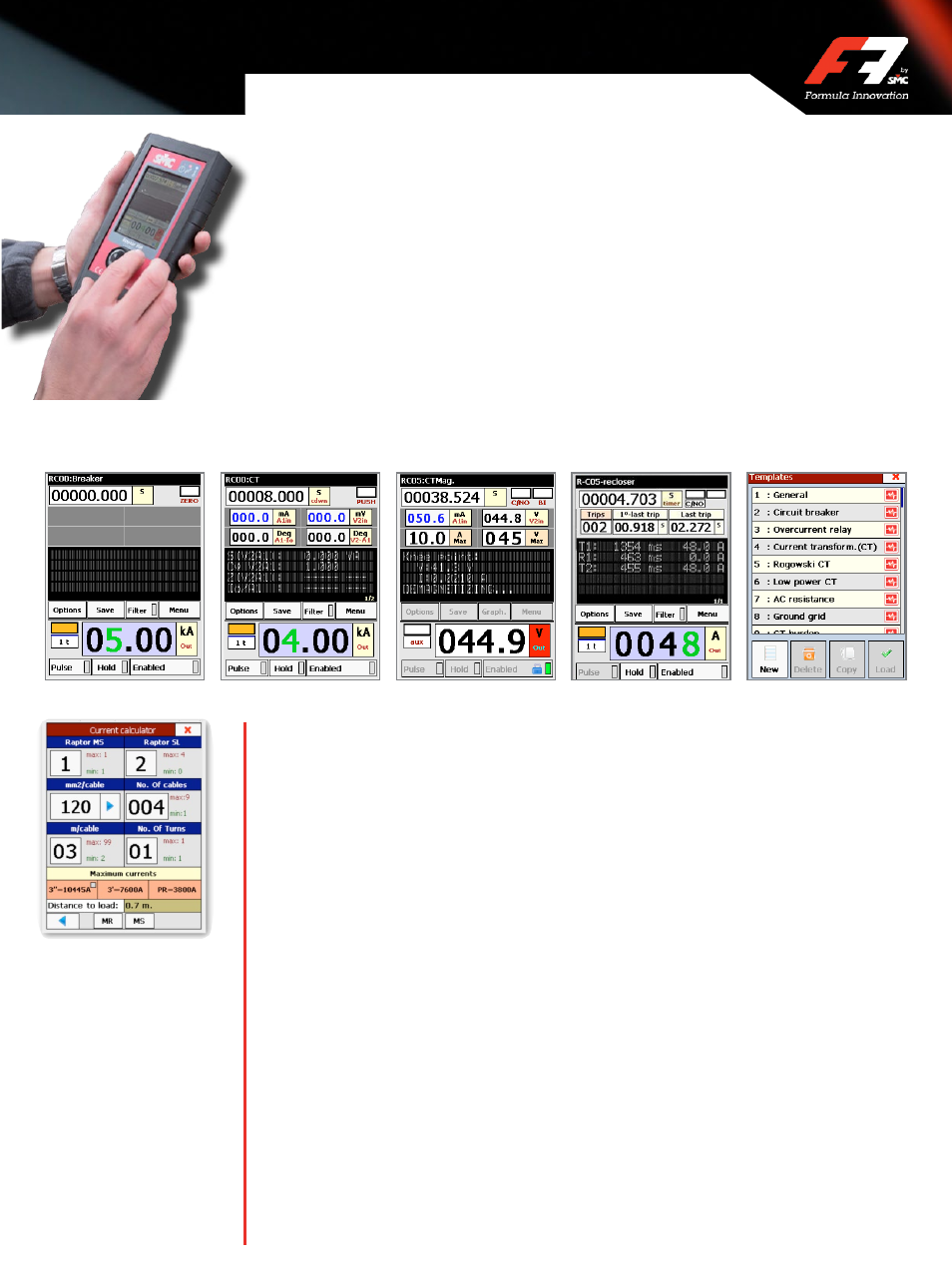

The Hand Held Control Unit, RAPTOR-HH, is the user-friendly interface from which the operator remotely controls and

monitors all the test process. The Raptor HH detects and configures the master and slave units automatically.

It provides an intuitive TFT touch screen, visible even in direct sunlight, with a wheel-and-click control that combined

with the existing test templates makes the test configuration and execution task extremely easy and fast.

The unit saves all the test configurations and results on its own memory, which can be further downloaded to an

external computer through USB connection and the RaptorSync software. This unit only weights 0.4 Kg and it is

developed with an ergonomic design optimized for correct handheld use, and nonslip laterals for a safer grip.

The Raptor HH is connected to the Master through a 5-meter cable that allows the user to stay at a convenient location

while the test set is working much closer to the load. For extreme cases, a 4-meter extender is available as an optional

accessory. The console’s back is magnetized, which allows the user to snap it quickly and safely on any iron surface for

a more comfortable operation.

Other advantages are: data storage and reporting, configuration assistance, software upgrades by internet, simplify

and reduce testing time, easy touch/turn operation, maximum test accuracy.

Test Templates allows the user to just select the appropriate template and start the test. Most common tests available

are: Overcurrent relay, MCB/MCCB, CT Ratio/Phase/Burden, CT ratio/phase with voltage, VT ratio/burden/phase,

Rogowsky CT, PT, contact Resistance, Ground Grid, CT magnetization curve and Knee point, Pulses, Recloser, etc.

APPLICATIONS

The combination of mobility, adaptability, automatic current regulation, high-tech, ease of use and versatility makes

the Raptor the best system available in the market for all major primary injection testing applications in and around

substations and power plants:

Primary Current Injection Testing

Primary Injection Testing is essential in commissioning and verifying a protection scheme. The secondary injection

test does not check all the components in the system, as it cannot provide the condition of the overall protection

installation, whether CTs have the correct ratio or polarity, or whether the secondary wiring is correct and serviceable,

and it does not mimic the operating conditions in service. Therefore, the Primary injection testing is the only way to

prove correct installation and operation of the entire protection scheme, and the Raptor has been specially designed to

meet all primary testing needs.

The Raptor´s variable output frequency extends the primary testing diagnostic with frequency sweep, offering test

frequencies different from the mains frequency, and thus enhancing its electrical testing capacity. Primary Test involves

the entire circuit; current transformer primary and secondary windings, relays, trip and alarm circuits, circuit breakers

and all wiring are checked. Primary injection tests are carried out after secondary injection tests, to ensure that

problems are limited to the VT’s and CT’s involved, circuit breakers, plus associated wiring, all other equipment in the

protection scheme having been proven satisfactory from the secondary injection tests. Hence it is often the last tests

performed in the commissioning and maintenance process, or after major modifications have been carried out, and

also as an invaluable aid to faultfinding.

The Raptor System: Applications

The Raptor Current Calculator is included as standard in the Raptor HH console and can also be installed on a PC. It is a

simple to use yet sophisticated tool that allows the user to quickly define the Raptor configuration and the number and

type of cables required as minimum to successfully accomplish a specific high current job, even before leaving the office.