The raptor system, Multifunctional primary testing system, Efficient power – Atec EuroSMC-Raptor User Manual

Page 2

2

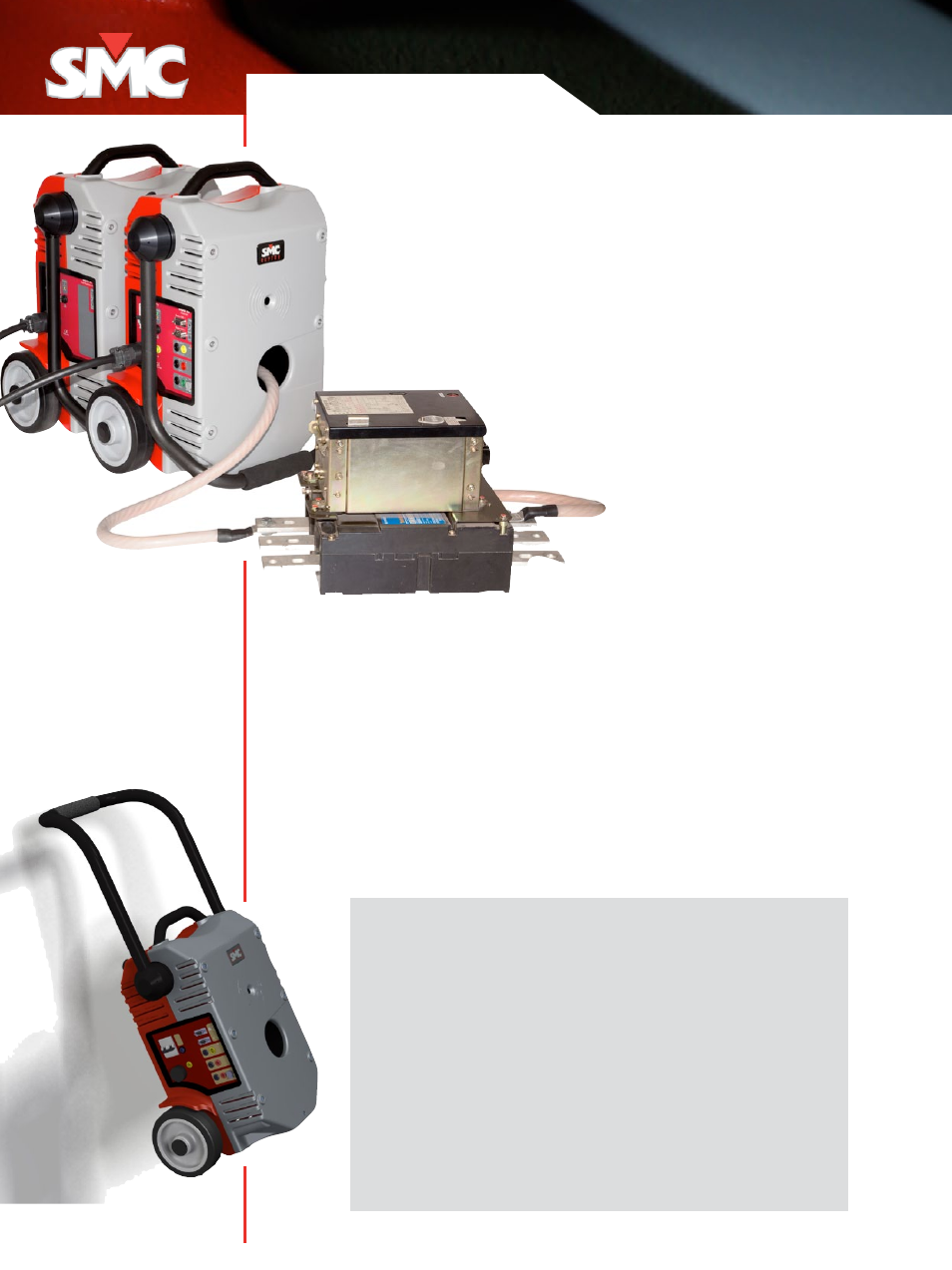

The Raptor System

Multifunctional Primary Testing System

The Raptor is a smart test system designed as the ultimate solution for the main primary test applications

required in the commissioning and maintenance of substations, marking the difference with respect to

existing equipment now being used. This new generation of Primary Injection Test System makes primary

testing easier, faster and more convenient.

The system consists of a Master unit which can be upgraded with up to three Slave sets which add

further power capacity to the system. The user is not limited to the power initially determined. In case

of more power required, Raptor sets can be added, or what is also very important, be left behind when

not needed.

In comparison with the big and heavy traditional variac-based equipment, the Raptor is designed

incredibly smaller and lighter than its predecessors, combining a revolutionary high current generation

technology, DSP based, with an automatic smart control, in a really transpor-

table set, less than 35 Kg and able to inject up to 15,000 A.

An additional advantage to the easy transport is that sets can be much clo-

ser to the devices tested, reducing the length of cables, and a significant

decrease in power losses by eliminating intermediate connections, thanks

to the new loop-through concept. The sets have in the middle a hole

to pass through the cables which are connected to the

load, forming in this way the injection circuit.

Efficient Power

The modern high-tech design of the Raptor system enables the

highest level of injection capability in terms of power and duty cycle, with an ease of use so far unknown in this type of

equipment. A touch-sensitive console allows the user to fully monitor and control the test process, including the storage

of results and test configuration tools.

The Raptor system provides automatic regulation of the magnitude to be injected, being stable regardless of the load or

power supply changes. Current output range is adjusted at all times according to application, taking advantage of the

modularity and versatility of the concentration of measurement and control functions in the Raptor Master unit, with a

unique capacity to adjust the voltage and current required through the number of spire turns used.

The Raptor also includes a powerful measurement section, extending the number of testing applications.

Raptor system includes factory configured tests, to automatically perform a large amount of the most common testing,

just by selecting the appropriate template and start the test. The user has also the possibility to easily make or modify

test templates.

UNIQUE FEATURES

SMALLEST SIZE AND WEIGHT FOR OUTSTANDING PORTABILITY

AUTOMATIC OUTPUT REGULATION WITH DIGITAL TECHNOLOGY

MULTIFUNCTIONALITY FOR MOST PRIMARY INJECTION TESTING

INSTANT COMBINATION OF UNITS BY INFRARED

LOOP-THROUGH HIGH CURRENT TECHNIQUE

FLEXIBLE MODULARITY AND ADAPTABILITY

MODERN, ROBUST AND UPGRADEABLE TECHNOLOGY

SMART HANDHELD CONTROLLER WITH TOUCH SCREEN

RESULTS STORAGE AND REPORTING

PREDEFINED TEST TEMPLATES