Increase test throughput – Atec Agilent-N3300A User Manual

Page 2

2

Increase Test Throughput

Today’s high volume manufacturing

requires optimization of test system

throughput, to maximize production

volume without increasing floorspace.

The N3300 Series electronic loads

can help you in a number of ways to

achieve this goal.

Reduced command processing time:

Commands are processed more

than 10 times faster than previous

electronic loads.

Automatically execute stored

command sequences:

“Lists” of

downloaded command sequences can

execute independent of the computer,

greatly reducing the electronic load

command processing time and com-

puter interaction time during product

testing.

Programmable delay allows for

either simultaneous or sequential

load changes:

This is the most

multiple output DC power supplies,

simulating real-life loading patterns,

with a minimum of programming

commands.

Buffer measurement data:

Voltage,

current, and power measurements

can be buffered for later readback

to the computer, reducing computer

interaction.

Control measurement speed vs.

accuracy:

Decrease the number of

measurement samples to achieve

greater measurement speed, or

increase the number of samples to

achieve higher measurement accu-

racy. You can optimize your measure-

ments for each test.

Control rising and falling slew rates

separately:

Reduce rate of loading

change when necessary for DUT

stability or to simulate real life condi-

tions, but otherwise change load

values at maximum rate.

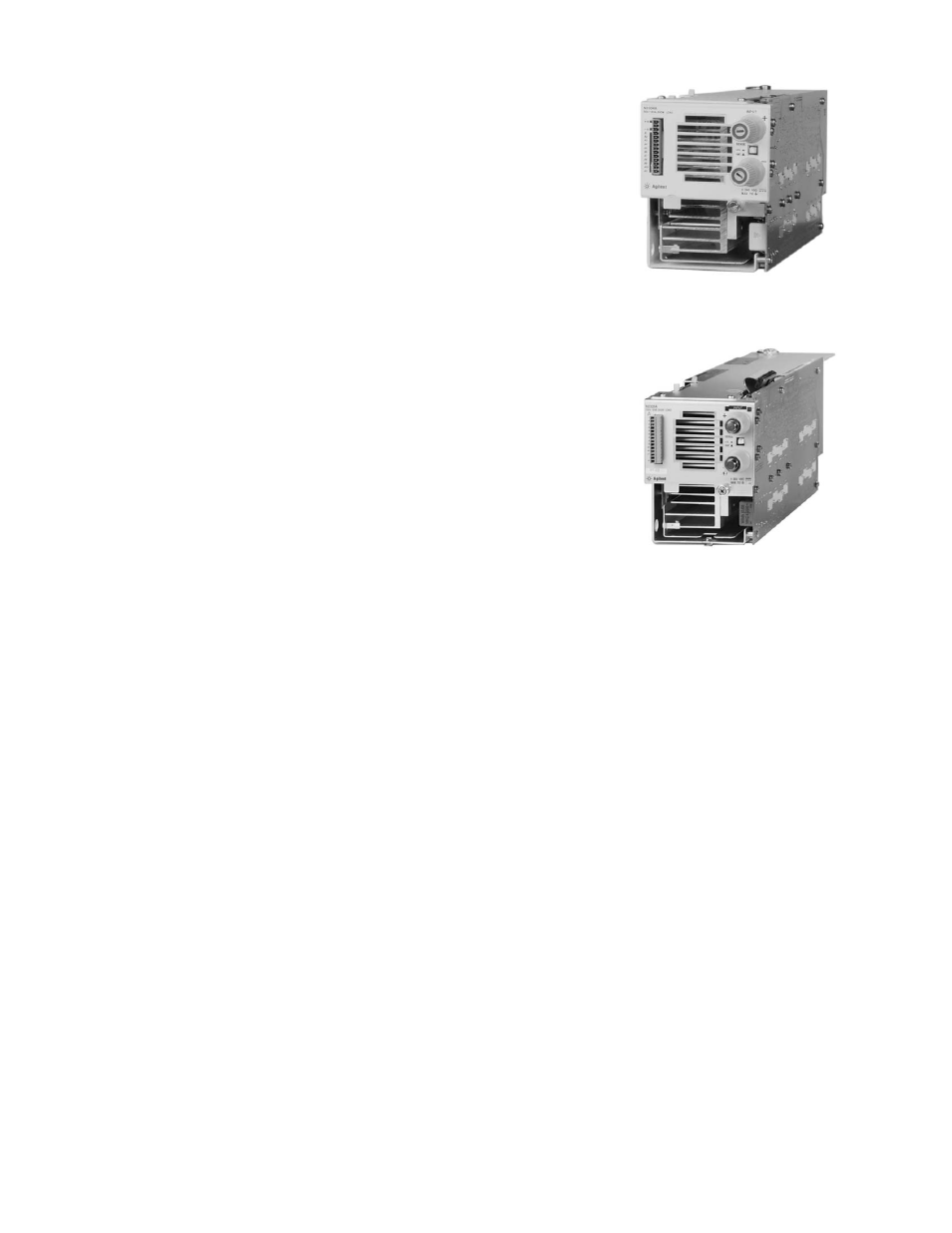

Standard DC connectors

Option UJ1 8 mm screw connectors

Increase System

Flexibility…for Both

Present and Future

Requirements

Most power supply and battery

charger test systems designed today

need to test a variety of products

and/or assemblies. In the future,

additional products or assemblies

may be needed. A flexible family

of electronic loads makes present

system design and future growth

much easier.

Test low voltage power supplies:

The N3300 Series electronic loads

operate with full stability down to

zero volts. Many other electronic

loads available today have been found

to become unstable in the operating

region below one volt. When design-

ing power supply test platforms, the

trend towards lower voltage require-

ments should be taken into account.

Refer to the specification and

supplemental characteristic tables

for details of lower voltage operating

characteristics.

Choose DC load connection method:

Automatic test systems need

consistency and reliability. Option

UJ1 8 mm screw connectors provide

a simple screw onto which your

wires, terminated with insulated ring

terminals, may be securely mounted.

This optional connector is specifically

designed for test systems. Wires may

exit the plastic cover in any direction,

and multiple wires may be placed on

each screw terminal for easy parallel

load connections. Up to AWG 4 wire

may be used.

Applications which require repeated

connections/disconnections are bet-

ter suited to the standard connector.

The standard connector accepts an

unterminated wire, and may be hand-

tightened. This connector is specifi-

cally designed for bench applications

and short-term automated tests.

Design a system to test a variety

of products:

This series consists of

2 mainframes and 6 modules. The

N3300A mainframe is full rack width.

It has 6 slots. The N3301A mainframe

is half rack width. It has 2 slots.

Any assortment of the 6 different

modules can be configured into these

mainframes, up to the slot capacity.

The N3302A (150 watts), N3303A

(250 watts), N3307A (250 Watts) and

N3304A (300 watts) each require

one slot. The N3305A (500 watts)

and the N3306A (600 watts) each

require 2 slots. The electronic load

can be configured to supply exactly

what you need now, and this modular

design also allows for easy future

reconfiguration.

Test high current power supplies:

Electronic load modules can be oper-

ated in parallel to provide additional

current sinking capability.