Specifications, Safety, Storing, analyzing and reporting – Atec Baker-DX Series User Manual

Page 3: Dc motor analysis, Physical characteristics

The Baker DX can store up to 200 results per folder for quick, easy

analysis and reporting. The data is also stored in a chart for accurate

and easy armature analysis. All interpoles and field coils can be easily

analyzed and stored in the Baker DXs multi-result file management

system.

Specifications

Physical characteristics

Weight: 15,4 kg

(34 lbs.)

Dimensions: 48,3 Ч 20,3 Ч 58,4 cm

(19 Ч 8 Ч 23 in.)

Power requirements: 100 to 240 V AC, 50/60 Hz, 2,5 A

Internal memory: 2 GB

Printer interface: USB/PCL 5 type printer

External connectors: RLC leads, Footswitch, remote E-stop safety

lights, SKF Power Pack, Ground

User interface: Color VGA touch screen

Safety

SKF built the Baker DX unit with customer safety in mind. The Baker

DX has successfully passed all the safety requirements to obtain the

CE mark. There are LEDs on the Baker DX unit that indicate to the

operator when the leads are energized. 40 kV test leads are utilized

to provide the most accurate readings and operator protection. The

Baker DX can also be configured with safety lights to warn all in the

area that testing is in operation.

Storing, analyzing and reporting

Storing data at incoming inspection, during winding and at final

assembly is made easy with the Baker DX multi-test storing capabili-

ties. The Baker DX has the ability to store multiple test results within

one folder and automatically attaches a time and date stamp. Utiliz-

ing the scroll button, the data can quickly and easily be reviewed.

Enter nameplate data utilizing the touch screen and print directly

to a printer through the USB port. Keep your company brand in front

of your customer by loading your logo in the Baker DX software so

every report has your logo at the top of the page. Screen images can

also be exported through the USB memory device for customers

who would like an electronic form of the data.

DC motor analysis

DC testing is a breeze with the new Baker DX. Both bar to bar and

span testing can be performed on a DC armature to thoroughly ana-

lyze the armature for shorts, opens, unbalances, turn to turn weak

insulation, unbalances in the coils and damaged or mis-connected

equalizers. Perform a bar to bar test with the AT101 ZTX. The ZTXs

impedance matching transformer is the best, most comprehensive

method to analyze low impedance coils in DC motors.

When span testing, a number of bars are spanned with the ATF02

fixture. The Baker DX can be placed in impulse mode and the arma-

ture can be tested rapidly with the touch of the start button. Utilizing

the span or ZTX to test armatures, the Baker DX software is capable

of automatically calculating the EAR. This method of analyzing the

waveform reduces the possibility of missing a fault in the armature.

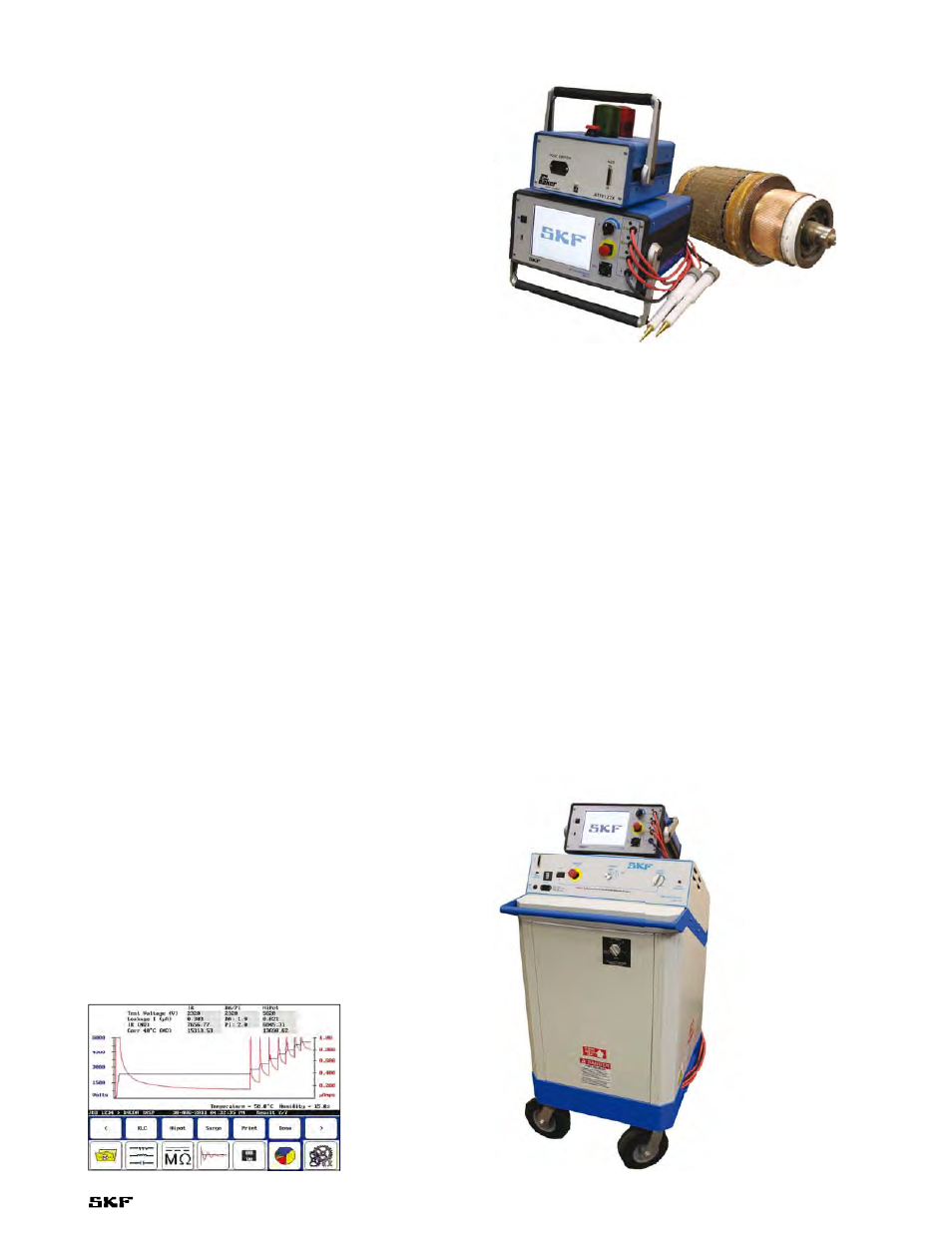

DC testing screen.

Baker DX with the SKF Static

Motor Analyzer Baker 30.

Baker DX with the AT101 ZTX.

3