Coil testing, Operator interface and operation, Flexible modular design – Atec Baker-DX Series User Manual

Page 2: Hardware and software

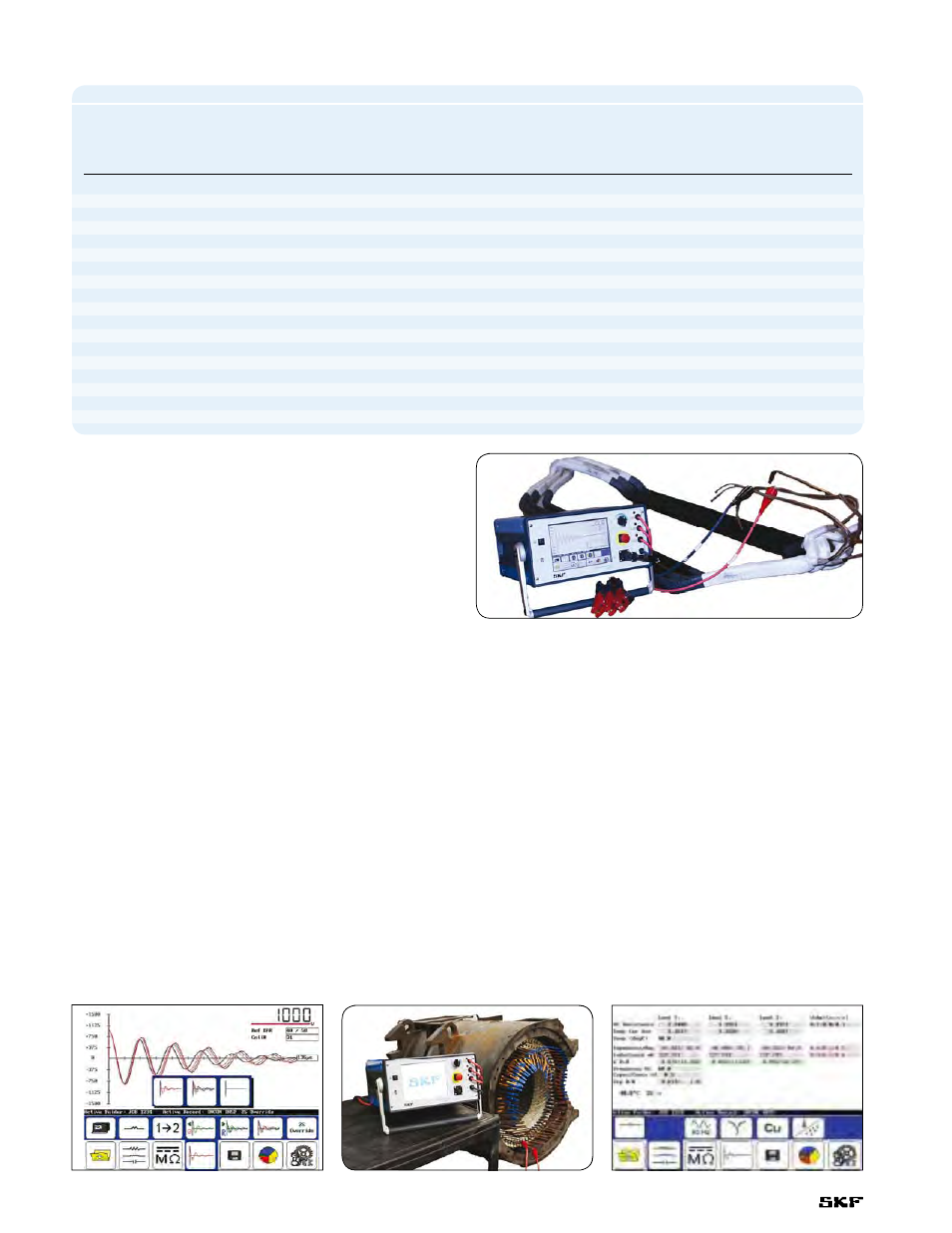

Coil testing

The Baker DX unit is among the first on the market to have specific

coil testing software. The Baker DX unit can be placed into an

impulse mode for quick application of voltage to the coils. The soft-

ware can store and display up to 200 waveforms on the screen for

quick analysis of coil condition. Utilize SKFs Error Area Ratio (EAR)

method to calculate the differences between the coils for quick, accu-

rate analysis of the data. The EAR calculation greatly reduces opera-

tor error and automatically indicates a defective coil when the result

is out of the programmed tolerance level. Report and analyze your

data easily with bar charts to help locate and report faulty coils, and

for an at-a-glance summary of all coils tested.

Operator interface and operation

The 12,7 × 17,0 cm (5.0 × 6.7 in.) touch and color display is an

industrial, ruggedized touch screen to handle the rough operation of

daily industrial use.

The operator interface has been developed with large icons for

easy touch operation, even with electrical gloves. The interface is

designed with a left-to-right flow to reduce the number of touches

and is intuitive and easy to operate. The software will automatically

prompt the operator to save the data if the save button is not

selected, reducing the possibility of lost data.

Flexible modular design

Hardware and software

The Baker DX can be built specifically to fit your needs. The unit can

be configured to only perform the surge and DC tests, or you can add

the resistance test. If you would like the ability to perform all avail-

able tests, add the Inductance, Impedance, Phase Angle and Capaci-

tance tests to take advantage of one of the most comprehensive

motor analyzers on the market. The Baker DX is available in a 4, 6 or

12 kV unit. The 6 and 12 kV units can also be configured in a high

output (HO) version to supply additional energy when surge testing

to properly test larger HP motors. If higher voltage is needed, any of

these units can act as a host for a Baker PP24, 30 or 40 kV power

pack. DC motors can also be tested with the Baker DX by utilizing the

AT101 ZTX or adding a span testing fixture.

Table 1

Tests and capabilities of the Baker DX unit.

Failure modes

Winding

resistance IR test

DA/PI

test

DC step

voltage

DC

HiPot

Surge

Inductance Capacitance

Impedance

Phase

angle

D/Q

Weak insulation turn-turn

X

Weak insulation phase-phase

X

Weak insulation coil-coil

X

Turn-turn shorts

X

X

X

X

X

X

Phase-phase shorts

X

X

X

X

X

X

Coils-coils shorts

X

X

X

X

X

X

Open coils

X

X

X

X

X

X

Reversed coils

X

X

X

X

X

Unbalanced phases

X

X

X

X

X

X

Weak ground wall insulation

X

X

X

X

Dirty windings

X

X

X

X

X

Moisture

X

X

X

X

X

Feeder cables

X

X

X

X

X

Motor lead line connections

X

RLC measurements screen.

Testing individual coils within the stator.

Coil testing screen.

Testing a coil utilizing the Baker DX.

2