3 recommended torque values, 4 cabling layout, 5 alarms – Alpha Technologies CXDS-M 600_600-19 User Manual

Page 22

9400002-J0 Rev A

20

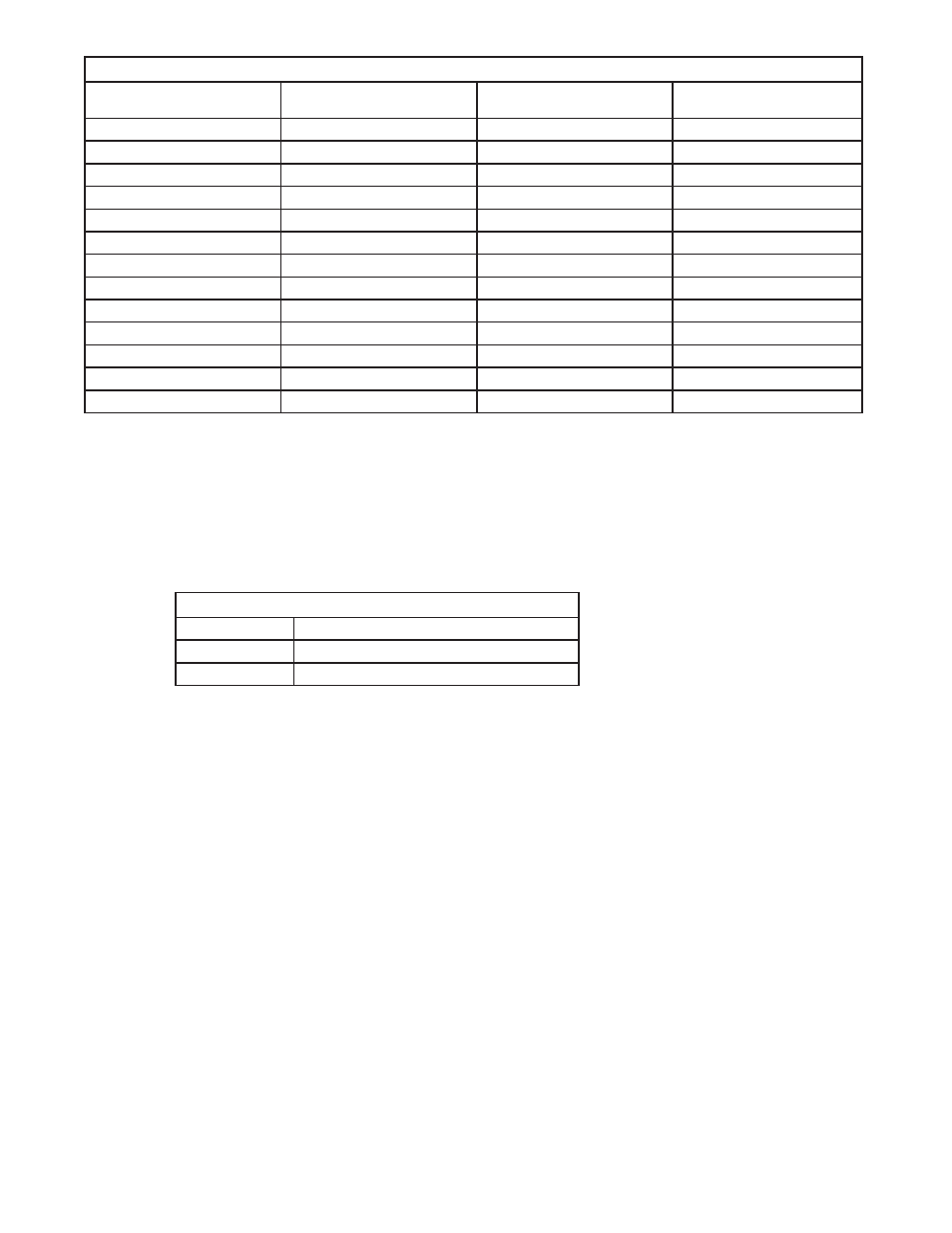

Table C — Cable size equivalents (AWG to Metric)

Cable size (see notes 1

and 2)

Circular mils

Square millimeters

Equivalent metric cable

6 AWG

26250

13.30

16

4 AWG

41740

21.15

25

2 AWG

66370

33.63

35

0 AWG (or 1/0)

105600

53.48

50 or 70

00 AWG (or 2/0)

133100

67.42

70

0000 AWG (or 4/0)

211600

107.2

120

313 MCM (or kcmil)

313600

159

150 or 185

350 MCM (or kcmil)

350000

177.36

185

373 MCM (or kcmil)

373700

189

185 or 240

500 MCM (or kcmil)

500000

253.36

300

535 MCM (or kcmil)

535300

271

300

750 MCM (or kcmil)

750000

380.00

400

777 MCM (or kcmil)

777700

394

400

5.1.3 Recommended Torque Values

Recommended torque values for connection to the power system:

x

Clear hole connections (nut and bolt)

x

PEM studs

x

PEM threaded inserts

x

Thread formed connections (in copper bus bar)

Table D — Recommended torque values

1/4"

8.8 ft-lbs (105 in-lb)

3/8"

32.5 ft-lbs (390 in-lb)

1/2"

73 ft-lbs (880 in-lb)

SAE Grade 5 hardware is required for these torque values.

5.1.4 Cabling Layout

The cabling at the time of installation is very straightforward.

x

The DC input cables connect to the top BDFB at the rear.

x

The load cables from the BDFB fuse/breaker exit the unit through the top. Open the front door of the

BDFB to access fuse/breaker connections.

x

All signaling wires (for example, alarms from the CXC Controller) interfacing with the outside world

exit the BDFB through the top or bottom.

5.1.5 Alarms

All applicable alarms should be connected to the local alarm-sending unit from the power system. The CXC sys-

tem controller provides form “C” relay contacts for interconnection.