13 accessories – Elmo Rietschle L-BV7 User Manual

Page 44

610.48060.40.000

44 / 64

© Gardner Denver Deutschland GmbH

Accessories

13 Accessories

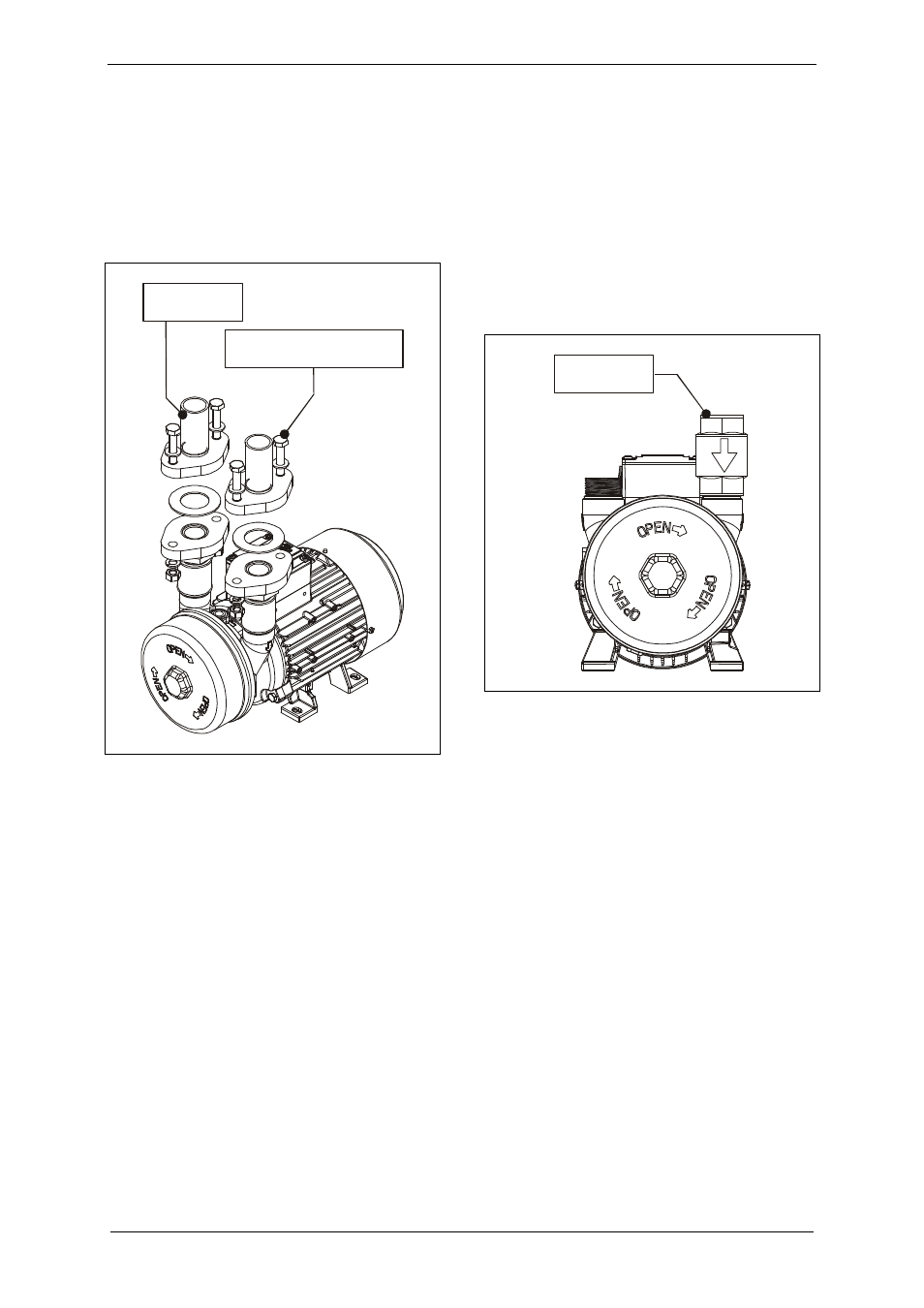

13.1 Flanges

The pipes on the intake and discharge side are

connected to intake and discharge connections

via the flanges.

See Fig. 17, Pg. 44.

2BV7 06: G1

2BV7 07: G1½

2BV7 06: 30 Nm (22.13 ft lb)

2BV7 07: 50 Nm (36.88 ft lb)

Fig. 17: Flanges

Mounting

The flanges are mounted when connecting the

pipes/hoses, as described in Chapter 7.3,

"Connecting pipes/hoses (vacuum

pump/compressor)", Pg. 25.

Proceed as follows:

Screwing flanges onto intake and discharge

connections.

Use commercially available liquid sealant

(e.g. Loctite) when doing so.

Tightening torque: dependent on the

sealant.

Screw intake and discharge connections

onto flanges.

Use commercially available liquid sealant

(e.g. Loctite) when doing so.

Tightening torque: dependent on the

sealant.

13.2 Non-return

valve

The non-return valve is basically a valve with a

plate seat. Its function is to prevent the

pumped gases/vapors as well as the operating

liquid from flowing back out of the pump in

case the operation of the pump-motor unit is

interrupted. It is mounted on the inlet

connection of the unit for this purpose.

See Fig. 18, Pg. 44.

2BV7 06: G1

2BV7 07: G1½

Fig. 18: Non-return valve

Mounting

The non-return valve is mounted when

connecting the pipes/hoses, as described in

Chapter 7.3, "Connecting pipes/hoses

(vacuum pump/compressor)", Pg. 25.

Proceed as follows:

Screw on the non-return valve with the

arrow pointing downward on the inlet

connection.

Use commercially available liquid sealant

(e.g. Loctite) when doing so.

Tightening torque: dependent on the

sealant.

Screw the inlet pipe onto the non-return

valve.

Use commercially available liquid sealant

(e.g. Loctite) when doing so.

Tightening torque: dependent on the

sealant.