Elmo Rietschle L-BV7 User Manual

Page 40

610.48060.40.000

40 / 64

© Gardner Denver Deutschland GmbH

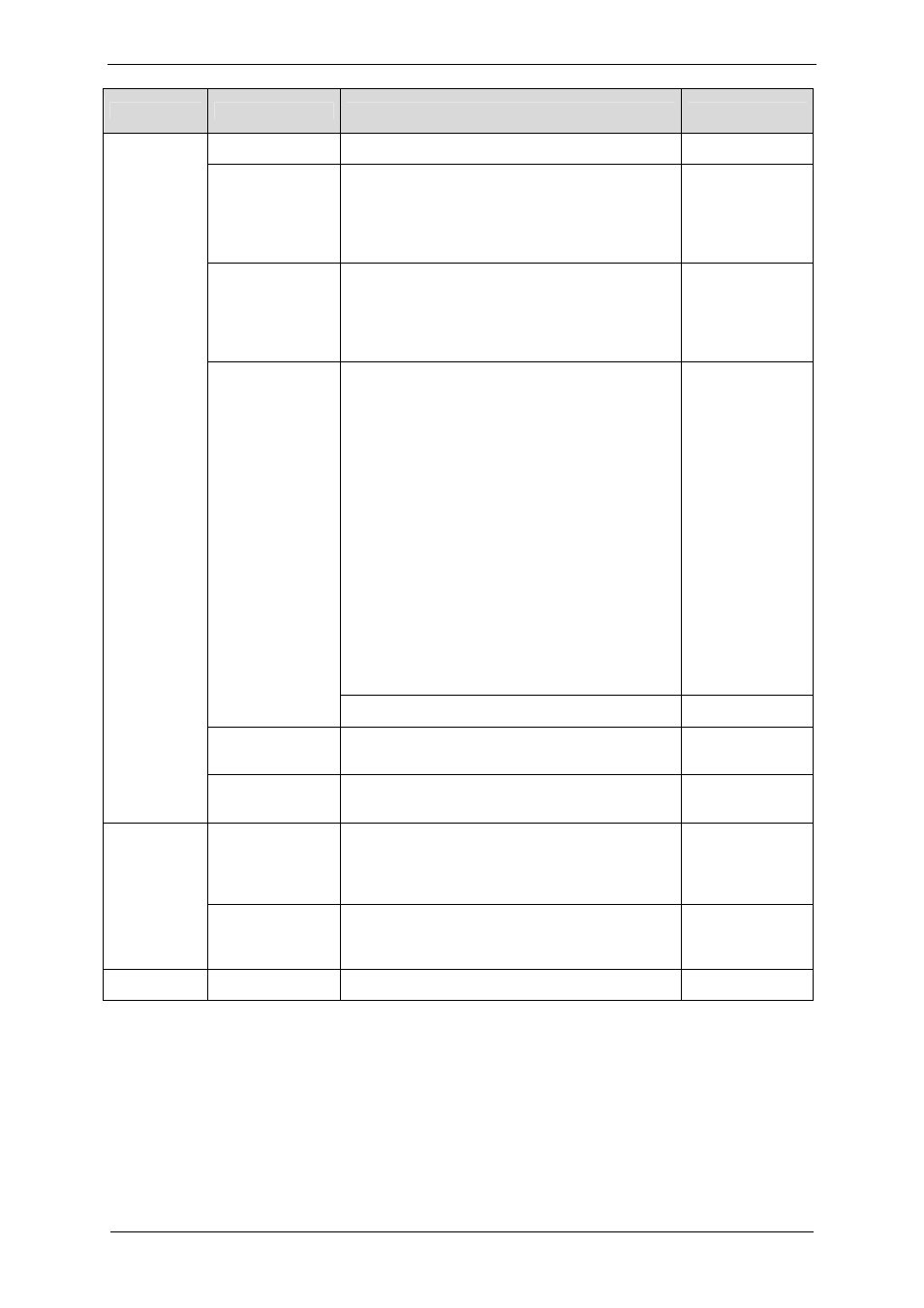

Servicing

Fault

Cause

Remedy

Carried out by

Unit too small.

Use larger unit.

Operator

Operating-liquid

flow too low.

Increase operating-liquid flow rate to up to 2x the

nominal flow rate.

See Chapter 8.2, "Self-priming operation", Pg. 30

or Chapter 8.3, "Operation with operating-liquid

feed", Pg. 31.

Operator

Operating liquid

too warm

(nominal

temperature:

15°C [59 °F]).

Cool or increase operating-liquid flow,

See Chapter 8.2, "Self-priming operation", Pg. 30

or 8.3, "Operation with operating-liquid feed",

Pg. 31.

Operator

Inspect impeller. To do so, proceed as follows:

Shut unit down.

Drain the pump-motor unit as described in

Chapter 10.1, "Draining", Pg. 34.

Unscrew the housing with a 36 mm [

3

/

8

"]

wrench (in direction of arrow shown on

housing) (see Fig. 15, Pg. 38).

Remove

the

housing.

Examine the impeller for erosion.

Have the impeller replaced by Service if

necessary.

Screw on the housing again (opposite

direction of arrow shown on housing) and

tighten with a tightening torque of 50 Nm [36.9

ft lbs].

When commissioning the pump-motor unit,

proceed as described in Chapter 8,

"Commissioning", Pg. 28.

Operator

Erosion.

Replace affected components.

Service

Slight leak in the

system.

Seal leak in the system.

Operator

Unit

generates

insufficient

vacuum.

Mechanical seal

leaky.

Replace mechanical seal.

Service

Cavitation of

vacuum

pump/compressor

.

Connect cavitation-protection hose of liquid

separator (see Chapter 13.5, "Cavitation

protection", Pg. 49) or clean cavitation-protection

equipment.

Operator

Abnormal

screeching

noise.

Operating-liquid

flow rate too high.

Check operating-liquid flow rate and reduce if

necessary. See Chapter 8.3, "Operation with

operating-liquid feed", Pg. 31.

Operator

Unit leaky.

Seals defective.

Check seals.

Service