Elmo Rietschle L-BV7 User Manual

Page 31

© Gardner Denver Deutschland GmbH

31 / 64

610.48060.40.000

Commissioning

8.3

Operation with operating-liquid feed

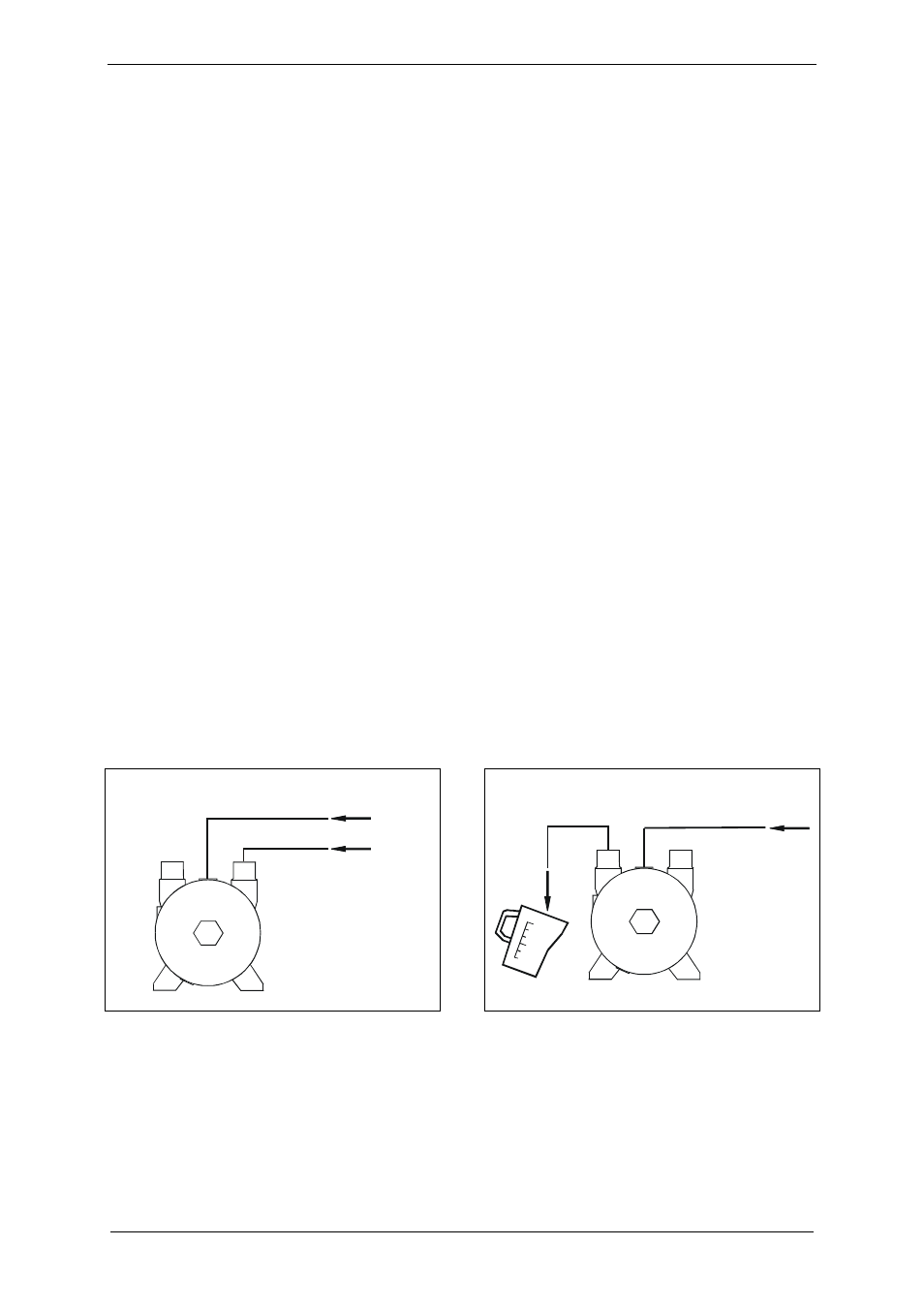

See Fig. 9, Pg. 31; and Fig. 10, Pg. 31, as well as Fig. 11, Pg. 32 and Fig. 12, Pg. 32.

Proceed as follows here:

Method A:

1) Set pre-pressure of operating liquid (Fig. 9,

Pg. 31):

Set a pre-pressure p

A

in the feed pipe for

the operating liquid (Item A) around

approx. 1 bar [14.5 psi] above the inlet

pressure p

B

in the inlet pipe (Item B).

2) Start up the unit:

For non-automatic operation (Fig. 11, Pg. 32):

Open the stop valve (Item 4) manually.

The operating liquid is fed in.

Switch on the unit.

For automatic operation (Fig. 12, Pg. 32):

Switch on the unit.

The solenoid valve (Item 4) opens

and the operating liquid is fed in.

Method B:

1) Start up the unit:

For non-automatic operation (Fig. 11, Pg. 32):

Open the stop valve (Item 4) manually.

The operating liquid is fed in.

Switch on the unit.

For automatic operation (Fig. 12, Pg. 32):

Switch on the unit.

The solenoid valve (Item 4) opens

and the operating liquid is fed in.

2) Check the operating-liquid flow rate:

with the flow meter (Fig. 11, Pg. 32, and

Fig. 12, Pg. 32, Item 2)

OR

by measuring the volume of operating liquid

per unit of time that exits at the discharge

connection with a graduated vessel

(Fig. 10, Pg. 31)

3) Set/correct the operating-liquid flow rate:

via the control valve (Fig. 11, Pg. 32, and

Fig. 12, Pg. 32, Item 3)

Nominal operating-liquid flow rate:

For nominal values, see Chapter 4.3,

"Operating conditions", Section "Nominal

operating-liquid flow rate", Pg. 17.

A

B

p = p + 1 bar

A

B

p = p + 14.5 psi

A

B

A

B

Fig. 9: Setting the operating-liquid flow rate:

Setting pre-pressure

Fig. 10: Setting the operating-liquid flow rate:

Measuring the volume with a graduated vessel

A Feed pipe for operating liquid

B Inlet

pipe

A Feed pipe for operating liquid

B Drain pipe for operating liquid