Gorman-Rupp Pumps 04E1-GHH 1076270 and up User Manual

Page 15

OM−03688

0 SERIES

PAGE B − 8

INSTALLATION

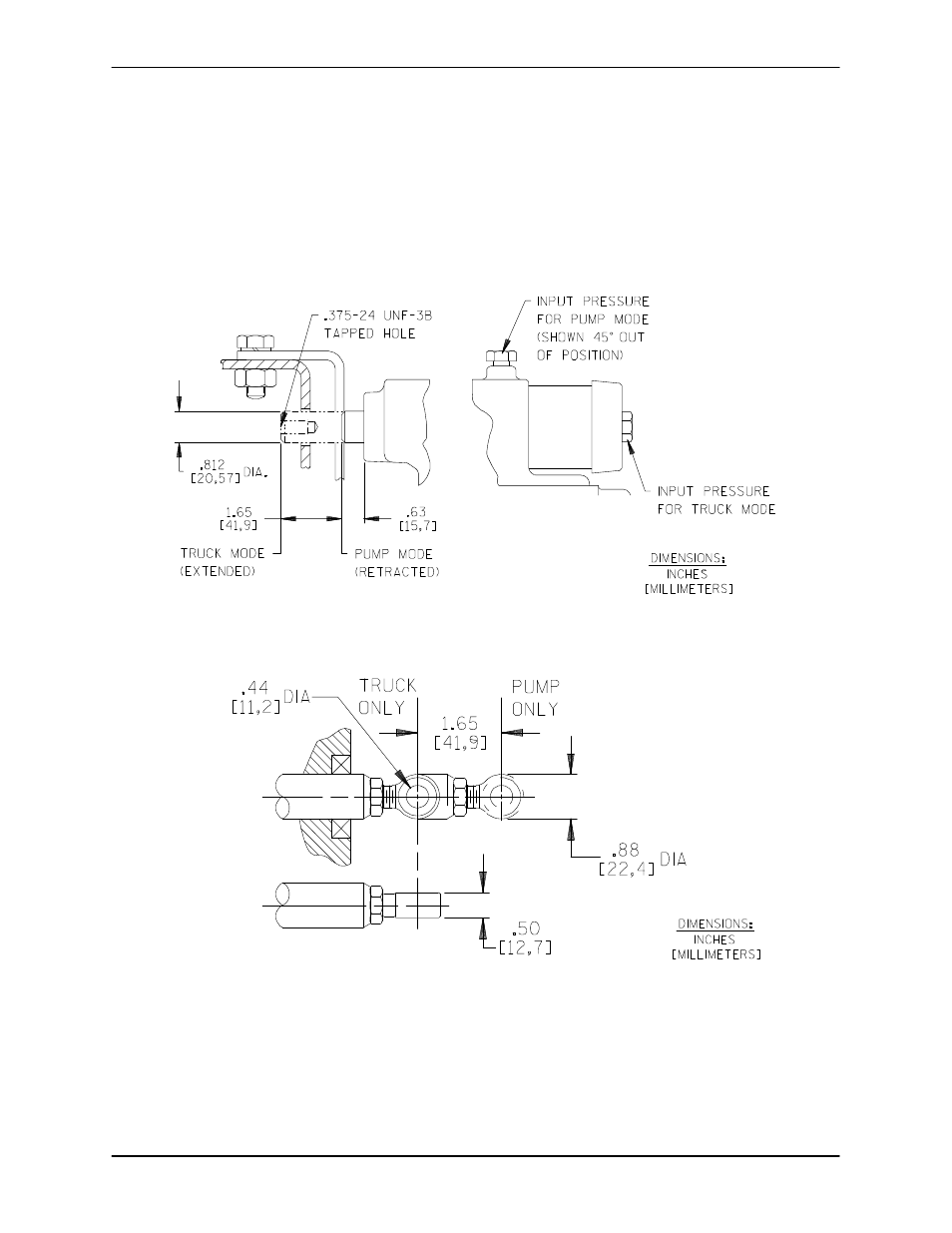

Proper operation of the gearbox air shift requires

air pressure of 70 to 140 psi (5,1 to 10,2 kg/cm

@)

and 1/4" air lines. The air line connection at the end

cap of the air cylinder is for vehicle operation, and

the air line connection at the top of the air shifter

cover is for pump operation. Seal all hose fittings

with Permatex" or equivalent compound.

When activated, the shifter rod travels through a

hole in the rear cross member. A customer-

supplied shift indicator (mechanical, electrical, or

air operated device) should be installed in this area

to indicate shifter mode to the pump operator. A

tapped hole is provided in the shaft for conve-

nience.

See Figures 4 and 5 for the approximate shaft trav-

el and hole size. See Figure 4, Section E for Air Shift

Kit parts.

Figure 4. Air Shifter Shaft Detail

Figure 5. Optional Manual Shifter

SUCTION AND DISCHARGE PIPING

Typical System Installation

Most petroleum handling vehicles perform both

fueling and defueling operations. This requires a

system utilizing flow-directing (FDF) valves, educ-

tors, related piping and safety accessories. Some

of the accessories are available from Gorman-

Rupp as optional equipment.

Refer to Figures 6 and 7 for illustrations of typical

piping systems used on refueling vehicles.