Gorman-Rupp Pumps 04E1-GHH 1076270 and up User Manual

Page 14

OM−03688

0 SERIES

PAGE B − 7

INSTALLATION

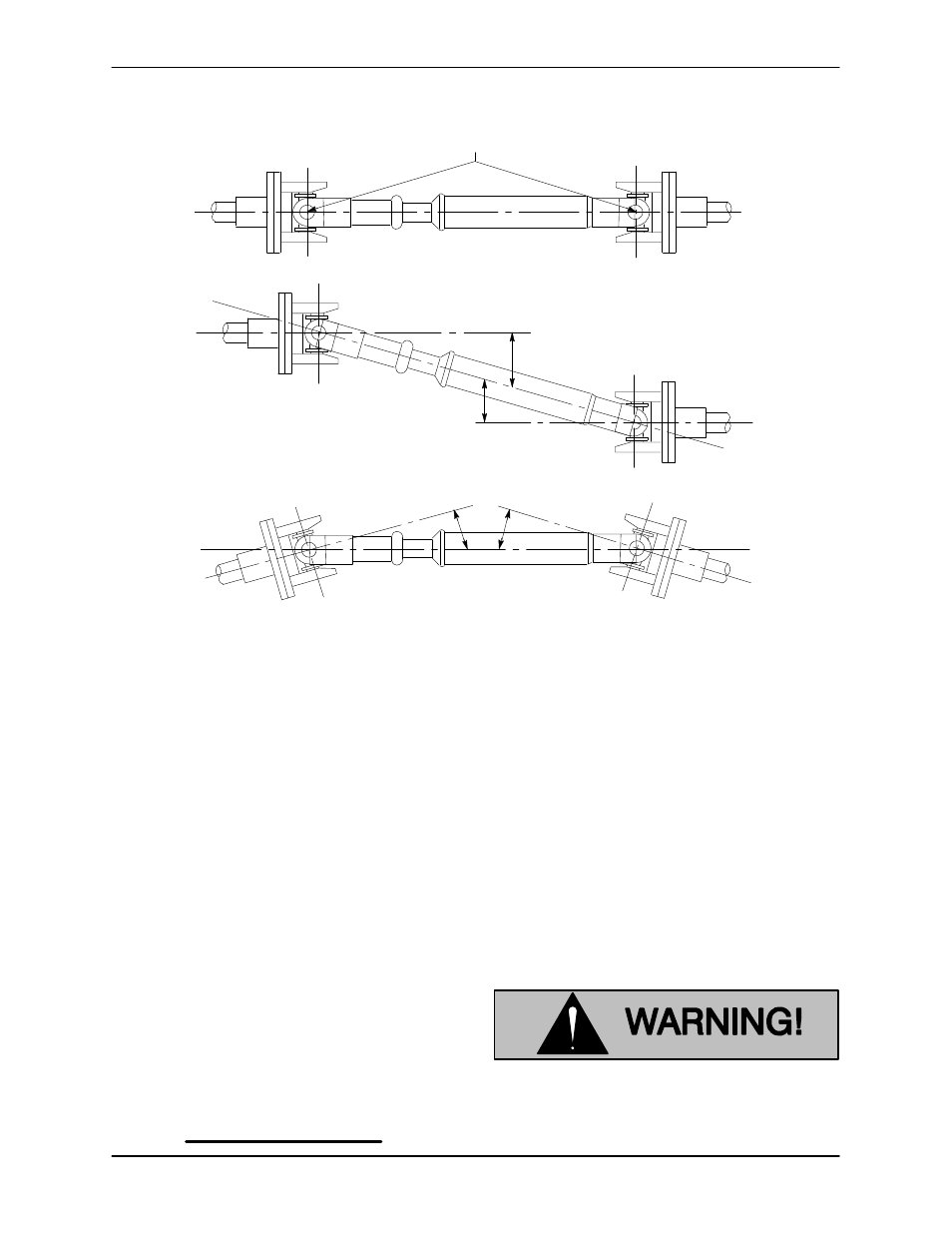

LUG ALIGNMENT

SHAFTS PARALLEL, ANGLES EQUAL

SHAFTS NOT PARALLEL, ANGLES EQUAL

LUGS MUST BE IN LINE, REGARDLESS

OF OPERATING ANGLE SHOWN BELOW

Figure 3. Drive Shaft Alignment

The alignment of the pump and its power source is

critical for trouble-free mechanical operation. Be-

fore checking alignment, make sure that the gear-

box mounting bolts are tight.

When connecting the universal joint drive shaft as-

sembly to a PTO unit, install, support, and align the

drive shaft in accordance with the manufacturer’s

instructions. The pump and the drive power source

are generally positioned so that shaft centerlines

are parallel and horizontal.

Make sure the horizontal and vertical joints are

equal. Limit the angles to 1 to 3

_ using a short

coupled joint, and less than 8

_ with a double joint

assembly. The maximum operating angle should

not exceed 15

_ (see Figure 3).

NOTE

Install a short coupled slip joint on the input side

and a double joint with slip on the output side of the

gearbox to attain the prescribed angles and elimi-

nate tensile stress on the shaft.

The input and output shafts should be completely

subassembled and checked for straightness and

balance before installation. Also check the univer-

sal joint yokes for proper alignment.

Check the direction of rotation of the PTO unit be-

fore starting the pump. The drive shaft must rotate

in the direction shown on the body of the pump,

gearbox, and/or decals, tags, and labels.

Gear Shift Connections

After the pump is mounted to the chassis, hook up

the air shift rod to the proper control stations.

Decals and tags vital to pump operation

were shipped loose with the pump.

These decals must be affixed in a promi-

nent place visible to the pump operator.