Cla-val – Cla-Val DBJ Series User Manual

Page 4

P a g e

3

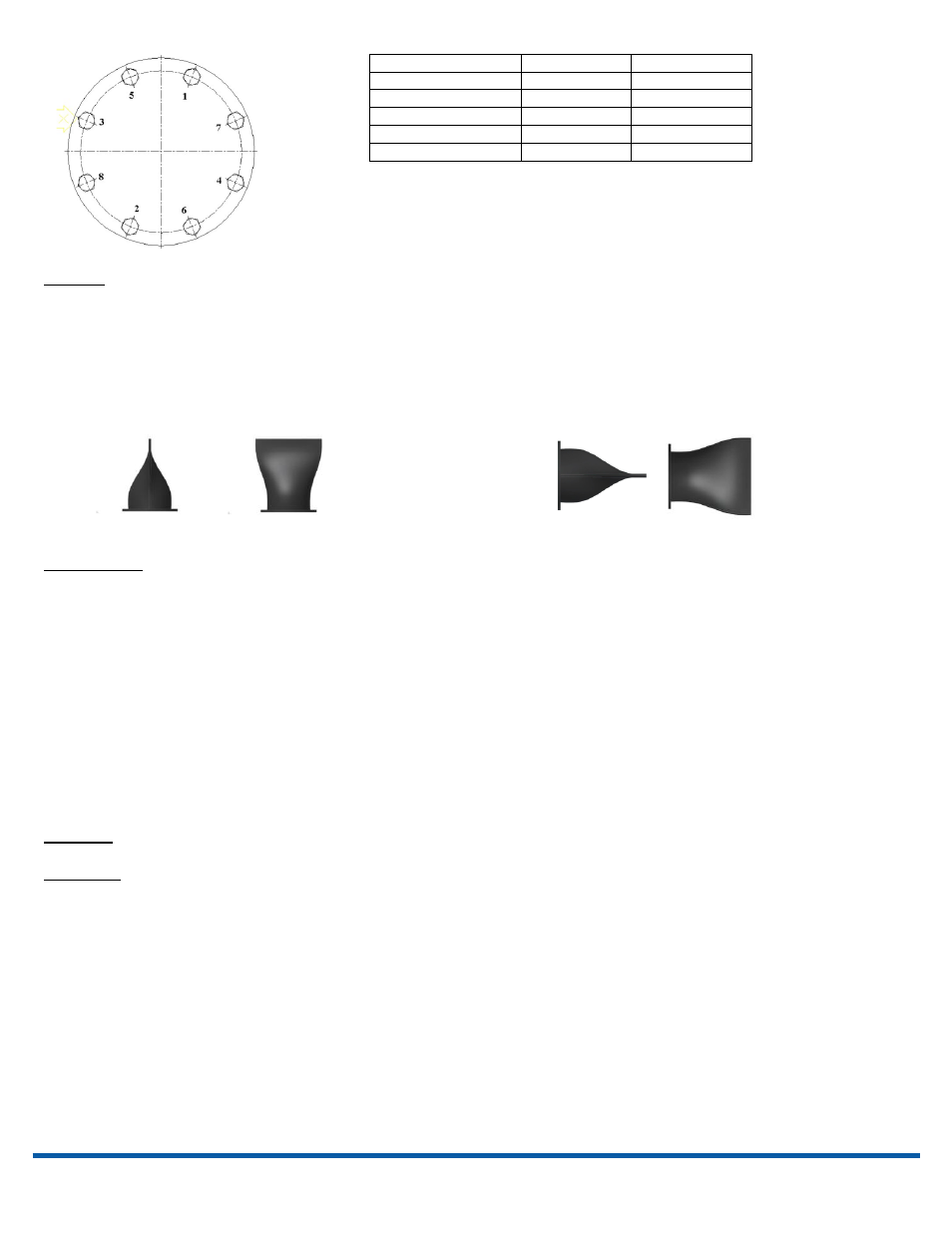

Figure 2

*Torque settings are approximate and are as recommended by the Fluid Sealing Association Std FSA PSJ70206 “Rubberr

Flanged Non- Metallic Expansion Joint Installation, Maintenance and Storage” Manual

.

a) To prevent leakage, the flange bolts should be retightened after one week of operation and checked periodically

thereafter.

b) Torque values are approximate. After installation, the system should be pressurized and examined to confirm a

proper seal.

Figure 3

Pipe Size ID (in)

Torque (ft-lbs)*

Torque (Nm)*

1 - 2

20

27

2.5 – 5

25

34

6 – 12

35

48

14 – 18

50

68

20 and larger

60

82

STORAGE

• Duckbill check valves should be stored vertically

( Figure 4a ) with the bill facing upward, not on their side

(Figure

4b )

Check valves should be stored in a cool, dry location with maximum ventilation.

Check valves should not be stacked ,

nor should anything be stored on top of their

bills. They should remain on a skid until ready for use.

Do not drop, bend, or twist the valve, as damage may occur.

The valve should be wrapped in black plastic to avoid contact with sunlight and/or ultra violet light. This will extend the shelf life.

Avoid exposure to light, electric motors, dirt, or chemicals.

Resilient check valves are subject to deterioration

(hardening and becoming

brittle)

when exposed to ozone and non-compatible chemicals

YES

Figure 4a

NO

Figure 4b

MAINTENANCE

Periodically, an inspection should be performed to verify the valve’s performance:

•

Inspect the tube and cover for cuts, checking, and fissures. Do not be alarmed if small cuts have formed in the outer cover. If necessary,

repairs can be made on site with a repair compound. If significant fissures are noticed where fabric is exposed and torn, the valve must be

replaced. Please contact Cla-Val factory for assistance if necessary.

•

If blisters, deformation, or delamination is noted inside the valve, this is an indication that the media or higher than expected temperatures

are attacking the tube. The valve should be replaced as soon as possible. Please contact Cla-Val factory for assistance if necessary.

•

Inspect the valve for entrapped foreign objects, which may have lodged between the lips of the valve and could prevent the valve from

checking.

•

Clean out ports are provided on DBJ bodies to allow drainage of the valve prior to performing any inspections or maintenance. (Note:

For DBJ Split Body valves, the drainage ports are located mid-way along the valve body).

•

Verify that there is clearance

between the bottom of the bill and the ground and that no debris is trapped there.

If a build up of debris occurs within the valve, line pressure should flush it out. In some instances, a wooden plank 1” x 4” or 1½” x 12” may be

temporarily inserted into the bill of the valve and rotated 90°. This will clear the check valve of any debris that may be trapped in the bill.

WARRANTY

All products supplied by Cla-Val

-

are guaranteed against defects resulting from faulty workmanship or materials for one (1) year from date of

shipment to Buyer. If any such product is found to be defective by reason of faulty workmanship or materials, then upon

written notice and return of the product, and at our sole discretion, the defe ctive product will be replaced or repaired by us free of charge at our

factory. Claims for labour costs and other expenses required to replace and/or transport such defective product or to repair damage resulting from

the use thereof will not be allowed by Cla-Val.

Our liability does not include consequential damages and is limited to the price paid for the defective

product.

Cla-Val shall not be bound by any other warranty other than the above set forth unless such warranty shall be agreed in writing by Cla-Val.

All Cla-Val literature is published in good faith and is believed to be reliable at time of print; however, due to product design changes, Cla-Val reserves

the right to make alterations from published materials at any time.

Formal approval drawings are available to confirm individual products upon

request at time of order.

•

•

•

•

•

CLA-VAL

Copyright Cla-Val 2014 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-DB Series