01 ul – Cla-Val 90-21 Technical Manual User Manual

Page 9

100-01 UL

Diaphragm Check (#1 )

1. Shut off pressure to the 90-21 valve by slowly closing upstream and

downstream isolation valves.

CAUTION: The valve cannot be serviced under pressure. Where

there are no isolation valves, It will be necessary to deactivate the sys-

tem.

2. Disconnect or close all pilot control lines to the valve cover and

leave only one fitting in highest point of cover open to atmosphere.

3.With the cover vented to atmosphere, slowly open upstream isola-

tion valve to allow some pressure into the valve body. Observe the

open cover tapping for signs of continuous flow. It is not necessary to

fully open isolating valve. Volume in cover chamber capacity chart will

be displaced as valve moves to open position. Allow sufficient time for

diaphragm assembly to shift positions. If there is no continuous flow,

you can be quite certain the diaphragm is sound and the diaphragm

assembly is tight. If the fluid appears to flow continuously

this is a good reason to believe the diaphragm is either damaged or it

is loose on the stem. In either case, this is sufficient cause to remove

the valve cover and investigate the leakage. (See “Maintenance” Sec-

tion for procedure.)

COVER CHAMBER CAPACITY

(Liquid Volume displaced when valve opens)

Valve size (inches)

Displacement

Gallons

Liters

1 1/4

.020

.07

1 1/2

.020

.07

2

.032

.12

2 1/2

.043

.16

3

.080

.30

4

.169

.64

6

.531

2.0

8

1.26

4.8

10

2.51

9.5

Freedom of Movement Check (#2)

4. Determining the Valve’s freedom of movement can be done after

all pressure is removed from the valve.

After closing inlet and outlet isolation valves and bleeding pressure

fro the valve, check that the cover chamber and the body are tem-

porarily vented to atmosphere. Insert fabricated tool into threaded

hole in top of valve stem, and lift the diaphragm assembly manu-

ally. The tool is fabricated from rod that is threaded on one end to

fit valve stem and has a "T" bar handle of some kind on the other

end for easy gripping. (See chart in step 4 of "Disassembly" Sec-

tion.)

Place marks on this diaphragm assembly lifting tool when the valve

is closed and when manually positioned open. The distance be-

tween the two marks should be approximately the stem travel shown

in the chart.

If the stroke is different than that shown, there is a good reason to

believe something is mechanically restricting the stroke of the valve.

The cover must be removed, and the obstruction located and re-

moved. The stem should also be checked for scale build-up. (See

"Maintenance" Section for procedure.)

Freedom of Movement Check (#2)

5. Test for seat leakage by applying inlet pressure to the cover

of the valve, wait until it closes, and then close the isolation

valve downstream of the Hytrol valve. Install a pressure gauge

between the two closed valves. Watch the pressure gauge. If

the pressure begins to climb, then either the isolation valve is

permitting pressure to creep back, or the Hytrol valve is allow-

ing pressure to go through it. Usually the pressure at the Hytrol

valve inlet will be higher than on the isolation valve discharge,

so if the pressure goes up to the inlet pressure, you can be

sure the Hytrol valve is leaking. If it goes up to the pressure on

the isolation valve discharge, the Hytrol valve is holding tight,

and it was just the isolation valve leaking.

Preventative Maintenance

Cla-Val Hytrol valves require no lubrication or packing and a

minimum of maintenance. However, a periodic inspection sched-

ule should be established to determine how the operating condi-

tions of the system are effecting the valve. The effect of these

actions must be determined by inspection.

Disassembly

Inspection or maintenance can be accomplished without remov-

ing the valve from the line.

1. Close upstream and downstream isolation valves to shut off

all pressure to the valve.

WARNING: Maintenance personnel can be injured and equip-

ment damaged if disassembly is attempted with pressure in the

system.

2. Loosen tube fittings to remove pressure form the valve body

and cover chamber. After pressure had been released from the

valve use care to remove the controls and tubing. Note and

sketch position of tubing and controls for reassembly. The

schematic on the E-90-21 sheet can be used as a guide when

reassembling pilot system.

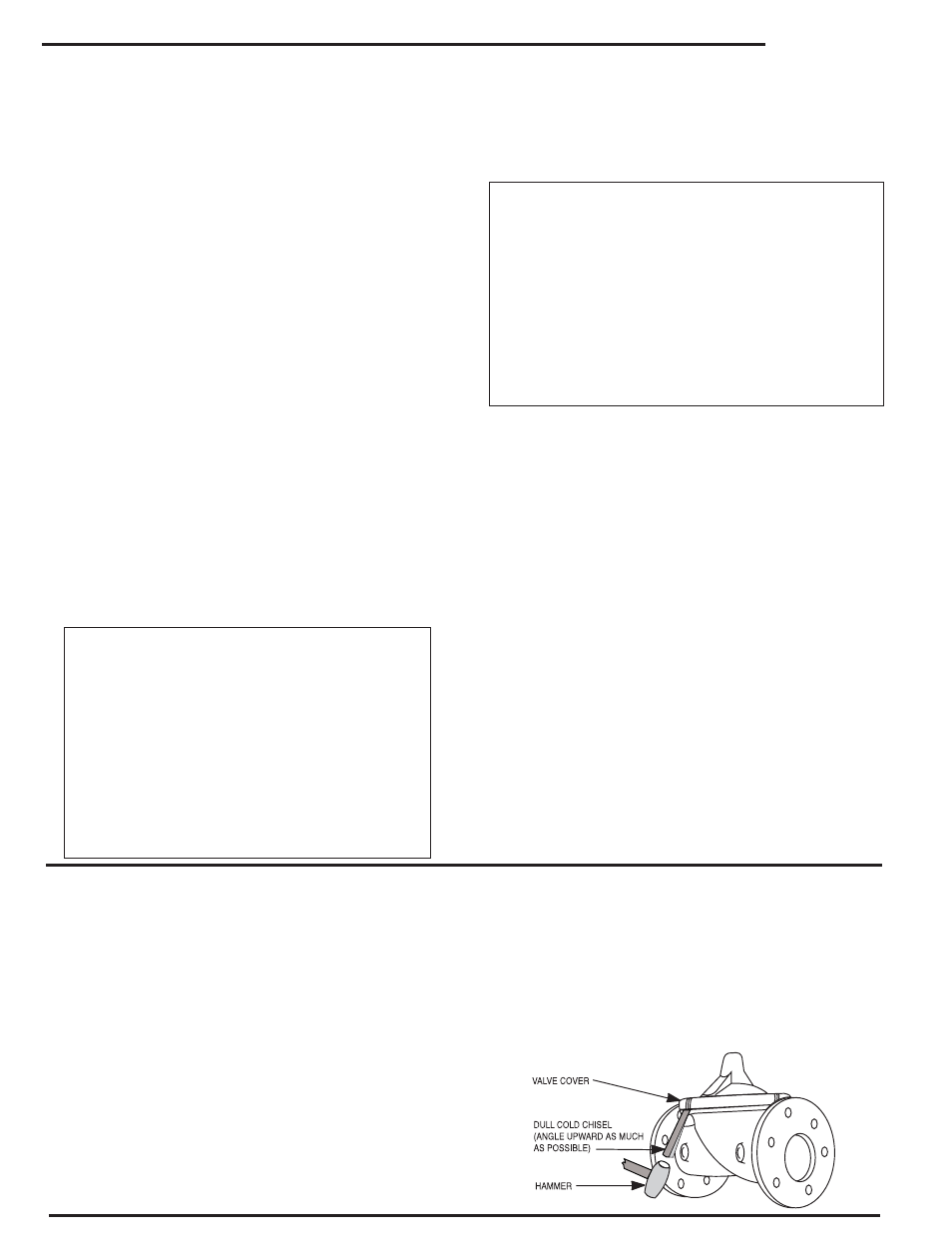

3. Remove cover nuts and remove cover. If the valve has been

in service for any length of time, chances are the cover will have

to be loosened by driving upward along the edge of the cover

with a dull cold chisel.

STEM TRAVEL

(Fully Open to Fully Closed)

Valve Size (inches)

Travel (inches)

Inches

MM

Inches

MM

1 1/4

32

0.4

10

1 1/2

40

0.4

10

2

50

0.6

15

2 1/2

65

0.7

18

3

80

0.8

20

4

100

1.1

28

6

150

1.7

43

8

200

2.3

58

10

250

2.8

71