01 ul – Cla-Val 90-21 Technical Manual User Manual

Page 10

Reassembly

1. Reassembly is the reverse of the disassembly procedure. If a new

disc has been installed, it may require a different number of spacer

washers to obtain the right amount of "grip" on the disc. When the di-

aphragm assembly has been tightened to a point where the di-

aphragm cannot be twisted, the disc should be compressed very

slightly by the disc guide. Excessive compression should be avoided.

Use just enough spacer washers to hold it firmly.

2. Make sure the stem nut is made up very tight. Attach a good fit-

ting wrench to the nut and give it a sharp "rap" rather than a steady

pull. Usually several blows are sufficient to tighten the nut for final

tightening. Failure to do so could allow the diaphragm to pull loose

and tear when subjected to pressure.

3. Carefully install the diaphragm assembly by lowering the stem

through the seat bearing. Take care not to damage the stem or bear-

ing. Line up the diaphragm holes with the stud or bolt holes on the

body. On larger valves with studs, it may be necessary

to hold the diaphragm assembly up while stretching the di-

aphragm over the studs.

4. Put spring in place and replace cover. Maker sure diaphragm

is laying smooth under cover.

5. Tighten cover nuts firmly using a cross-over pattern until all nuts

are tight.

Test Procedure After Valve Assembly

1. Check the diaphragm assembly for freedom of movement by

inserting a rod into the threaded hole in the top of the valve

stem and lifting the diaphragm assembly manually. The di-

aphragm assembly should move freely without any signs of

sticking or grabbing. (See "Freedom of Movement Check" sec-

tion.

2. Re-install the pilot system and tubing exactly as it was prior to

removal.

3. Follow steps under "Start-Up and Adjustment" Section in N-

90-21 UL Sheet.

When block and tackle or a power hoist is to be used to lift valve

cover, insert proper size eye bolt in place of the center cover plug.

On 8” valves only, there are 4 holds 3/8" - 11 size where jacking

screws maybe inserted to break cover loose from the body and then

4 eye bolts may be inserted for lifting purposes. Pull cover straight

up to keep from damaging the integral seat bearing and stem.

4. Remove the diaphragm and disc assembly from the valve body.

With smaller valves this can be accomplished by hand, pulling

straight up on the stem so as not to damage the seat bearing.

On large valves, an eye bolt of proper size can be installed in the

stem and the diaphragm assembly can be then lifted with a block

and tackle or power hoist. Take care not to damage the stem or bear-

ings. The valve won't work if these are damaged.

5. The next item to remove is the stem nut. Examine the stem

threads above the nut for signs of mineral deposits or corrosion. If

the threads are not clean, use a wire brush to remove as much of the

residue as possible. Attach a good fitting wrench to the nut and give

it a sharp “rap” rather than a steady pull. Usually several blows are

sufficient to loosen the nut for further removal. On the smaller valves,

the entire diaphragm assembly can be held by the stem in a vise

equipped with soft brass jaws before removing the stem nut.

The use of a pipe wrench or a vise without soft brass jaws scars the

fine finish on the stem. No amount of careful dressing can restore the

stem to its original condition. Damage to the finish of the stem can

cause the stem to bind in the bearings and the valve will not open or

close.

6. After the stem nut has been removed, the diaphragm assembly

breaks down into its component parts. Removal of the disc from the

disc retainer can be a problem if the valve has been in service for a

long time. Using two screwdrivers inserted along the outside edge

of the disc usually will accomplish its removal. Care should be taken

to preserve the spacer washers in water, particularly if no new ones

are available for re-assembly.

7. The only part left in the valve body is the seat which ordinarily

does not require removal. Careful cleaning and polishing of inside

and outside surfaces with 400 wet/dry sandpaper will usually re-

store the seat’s sharp edge. If, however, it is badly worn and re-

placement is necessary, it can be easily removed.

Seats in valve sizes 1 1/4” through 6” are threaded into the valve

body. They can be removed with accessory X109 Seat Removing

Tool available from the factory. On 8” and larger valves, the seat is

held in place by flat head machine screws. Use a tight-fitting, long

shank screwdriver to prevent damage to seat screws. If upon re-

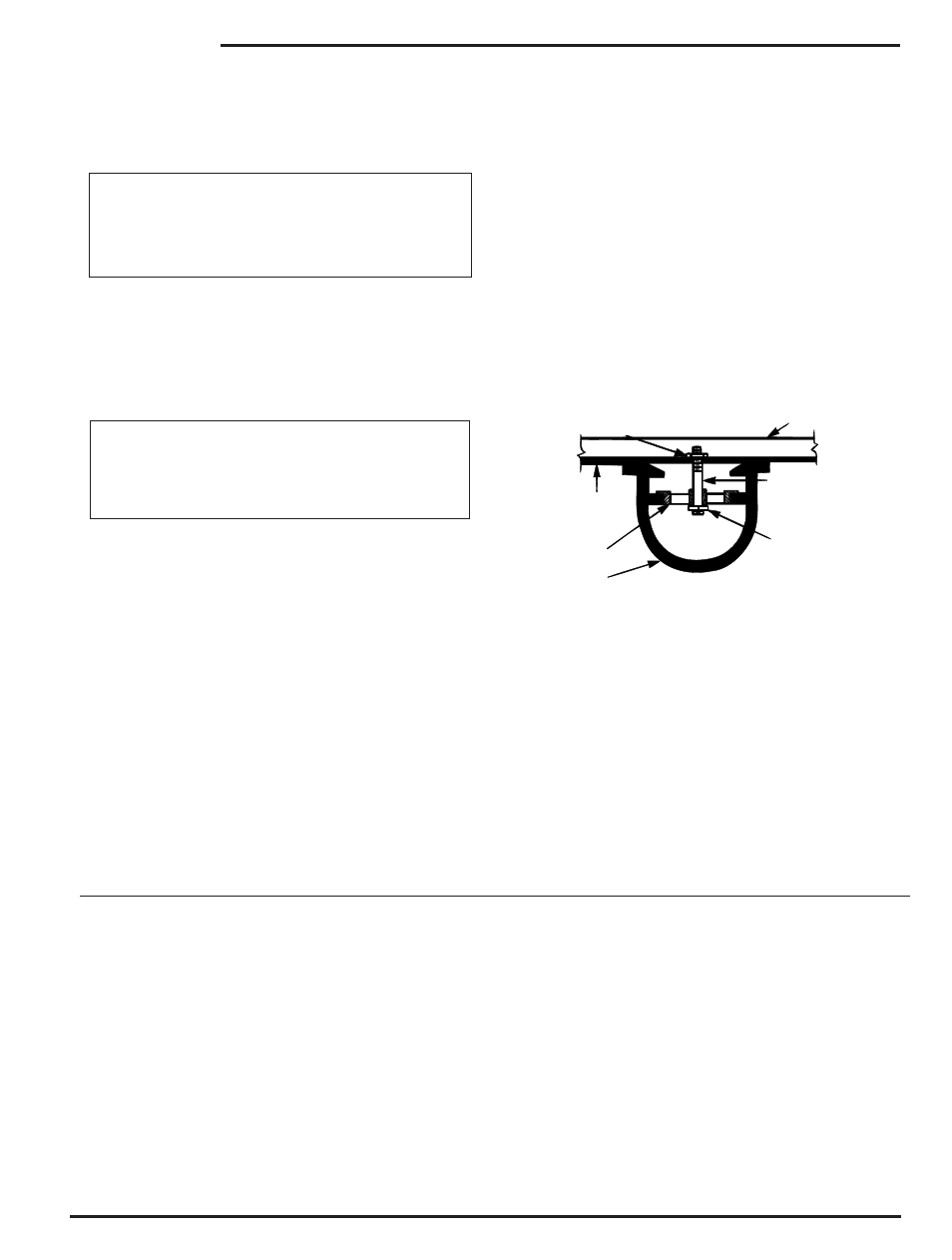

moval of the screws the seat cannot be lifted out, it will be neces-

sary to use a piece of angle or channel iron with a hole drilled in the

center. Place it across the body so a long stud can be inserted

through the center hole in the seat and the hole in the angle iron.

By tightening the nut a uniform upward force is exerted on the seat

for removal.

NOTE: Do not lift up on the end of the angle iron as this may force

the integral bearing out of alignment, causing the stem to bind.

Lime Deposits

One of the easiest ways to remove lime deposits from the valve

stem is to dip it in a 5-percent muriatic acid solution just long

enough for the deposit to dissolve. This will remove most of the

common types of deposits. CAUTION: USE EXTREME CARE

WHEN HANDLING ACID, RINSE PARTS IN WATER BEFORE

HANDLING. If the deposit is not removed by acid, the a fine grit

(400) wet or dry paper can be used with water.

Inspection of Parts

After the valve has been disassembled, each part should be ex-

amined carefully for signs of wear, corrosion, or any other abnor-

mal conditions. Usually, it is a good idea to replace the rubber

parts (diaphragm and disc) unless they are free of signs of wear.

Any other parts which appear doubtful should be replaced.

100-01 UL

VALVE STEM THREAD SIZE

Valve Size

Thread Size (UNF Internal)

1 1/4"—2 1/2"

10—32

3"—4"

1/4—28

6"—8"

3/8—24

COVER CENTER PLUG SIZE

Valve Size

Thread Size (NPT)

1 1/4"—1 1/2"

1/4"

2"—3"

1/2"

4"—6"

3/4"

8"

1"

NUT

ANGLE OR CHANNEL IRON

LONG STUD OR BOLT

NUT OR BOLT HEAD

DO NOT

LIFT

VALVE SEAT

VALVE BODY