Materials pressure ratings, Dimensions – Cla-Val 100-20KO User Manual

Page 2

Specifications

Model 100-20KO

Cla-Val Control Valves with KO ANTI-CAVITA-

TION Trim operate with maximum efficiency

when mounted in horizontal piping with the

main valve cover Up. We recommend isola-

tion valves be installed on inlet and outlet for

maintenance. Adequate space above and

around the valve for service personnel should

be considered essential. A regular maintenance

program should be established based on the

specific application data. However, we recom-

mend a thorough inspection be done at least

once a year. Consult factory for specific rec-

ommendations.

Pattern

Globe

Angle

Size

3" - 36"

4" - 6" - 8"

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Cast Steel

Bronze

Available Sizes

3" - 36"

3" - 16"

3" 16"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Stainless Steel is Standard

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Body & Cover

Pressure Class

Flanged

Grade

Material

ANSI

Standards*

150

Class

300

Class

ASTM A536

Ductile Iron

B16.42

250

400

ASTM A216-WCB

Cast Steel

B16.5

285

400

ASTM B62

Bronze

B16.24

225

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Valves for higher pressure are available; consult factory for details

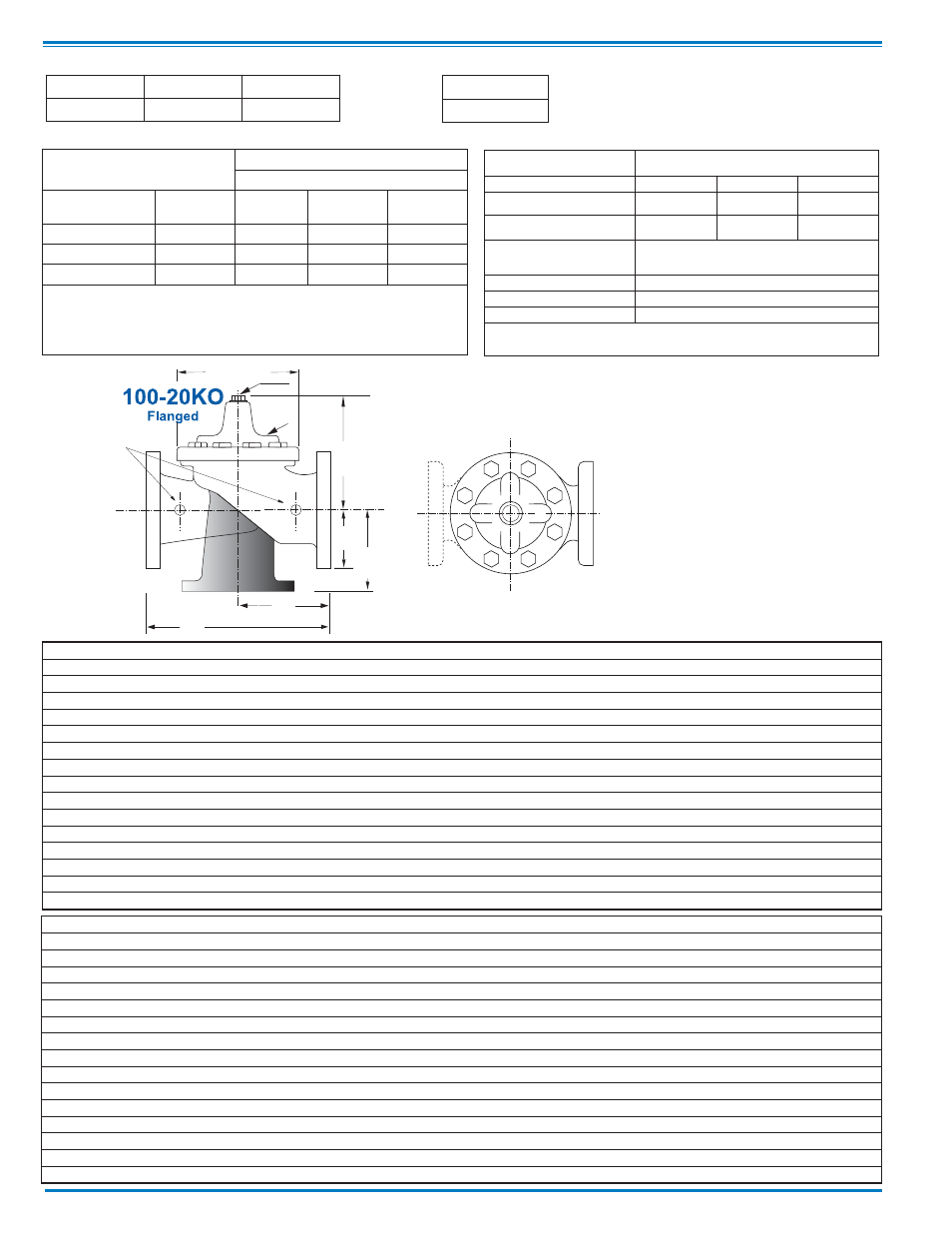

Dimensions

EE

D

E

Inlet

DD

AA

F

A

C

(MAX)

K

J

H

Inlet

Outlet

FF

B

(Diameter)

Valve Size (Inches)

3

4

6

8

10

12

14

16

18

20

24

30

36

A 150 ANSI

10.25

13.88

17.75

21.38

26.00

30.00

34.25

35.00

42.12

48.00

48.00

63.25

65.00

AA 300 ANSI

11.00

14.50

18.62

22.38

27.38

31.50

35.75

36.62

43.63

49.62

49.75

63.75

67.00

B Dia.

6.62

9.12

11.50

15.75

20.00

23.62

27.47

28.00

35.44

35.44

35.44

53.19

56.00

C Max.

7.00

8.62

11.62

15.00

17.88

21.00

20.88

25.75

25.00

31.50

31.50

43.94

54.60

D 150 ANSI

—

6.94

8.88

10.69

—

—

—

—

—

21.06

—

—

—

DD 300 ANSI

—

7.25

9.38

11.19

—

—

—

—

—

—

—

—

—

E 150 ANSI

—

5.50

6.75

7.25

—

—

—

—

—

15.94

—

—

—

EE 300 ANSI

—

5.81

7.25

7.75

—

—

—

—

—

—

—

—

—

F 150 ANSI

3.75

4.50

5.50

6.75

8.00

9.50

11.00

11.75

15.88

14.56

17.00

19.88

25.50

FF 300 ANSI

4.12

5.00

6.25

7.50

8.75

10.25

—

12.75

15.88

16.06

19.00

22.00

27.50

H NPT Body Tapping

.375

.50

.75

.75

1

1

1

1

1

1

1

1

2

J NPT Cover Center Plug

.50

.50

.75

.75

1

1

1.25

1.25

2

2

2

2

2

K NPT Cover Tapping

.375

.50

.75

.75

1

1

1

1

1

1

1

1

2

Stem Travel

0.6

0.8

1.1

1.7

2.3

2.8

3.4

3.4

4.5

4.5

4.5

6.5

7.5

Approx. Ship Wt. Lbs.

45

85

195

330

625

900

1250

1380

2365

2551

2733

6500

9120

Valve Size (mm)

80

100

150

200

250

300

350

400

450

500

600

750

900

A 150 ANSI

260

353

451

543

660

762

870

889

1070

1219

1219

1607

1651

AA 300 ANSI

279

368

473

568

695

800

908

930

1108

1260

1263

1619

1702

B Dia.

168

232

292

400

508

600

698

711

900

900

900

1351

1422

C Max.

178

219

295

381

454

533

530

654

635

800

800

1116

1387

D 150 ANSI

—

176

226

272

—

—

—

—

—

—

—

—

—

DD 300 ANSI

—

184

238

284

—

—

—

—

—

—

—

—

—

E 150 ANSI

—

140

171

184

—

—

—

—

—

—

—

—

—

EE 300 ANSI

—

148

184

197

—

—

—

—

—

—

—

—

—

F 150 ANSI

95

114

140

171

203

241

279

298

403

370

432

505

648

FF 300 ANSI

105

127

159

191

222

260

—

324

403

408

483

559

699

H NPT Body Tapping

.375

.50

.75

.75

1

1

1

1

1

1

1

1

2

J NPT Cover Center Plug

.50

.50

.75

.75

1

1

1.25

1.25

2

2

2

2

2

K NPT Cover Tapping

.375

.50

.75

.75

1

1

1

1

1

1

1

1

2

Stem Travel

15

20

28

43

58

71

86

86

114

114

114

165

191

Approx. Ship Wt. Kgs.

20

39

89

150

284

409

568

627

681

1157

1249

2951

3876

Operating Temp. Range

Fluids

-40° to 180° F