Materials, Dimensions, Pressure ratings – Cla-Val 350-01/3650-01 User Manual

Page 7

350-01/3650-01 Purchase Specifications

The 350-01/3650-01 Electronic Actuated Pressure Sustaining Control Valve shall have an integral hydraulic and electronic controller contained

in a NEMA 4 enclosure to provide the interface between remote telemetry and valve control. It will compare a selectable remote analog or

local set-point with a process variable signal or internal position sensor signal and automatically adjust the hydraulic pilot control until the main

control valve reaches desired set-point.

The electronic actuator will supply loop power for the process variable signal. Retransmission of the process variable shall be with an isolated

non-powered analog signal. The actuator speed will be infinitely adjustable between 1/3 and 5 RPM and will have an adjustable dead band.

In the event of an erroneous communications signal, actuator output will be capable of being limited to a predetermined process variable value.

If these signals (SP and /or PV) are lost, the valve shall remain under control of the pressure sustaining hydraulic control. The actuator can

also be programmed to drive the main valve to the open or closed position if these signals are lost.

All setup and adjustments will be capable of being made prior to placing the valve into service using actuator test points for signal

measurement and subsequent calibration. Actuator diagnostics will be displayed using LEDs. Manual operation of the hydraulic pilot will be

fully adjustable using a non-rotating handwheel.

The Electronic Actuated Pressure Sustaining Control Valve shall be the Cla-Val Model 350-01/3650-01 as manufactured by Cla-Val,

Newport Beach, CA.

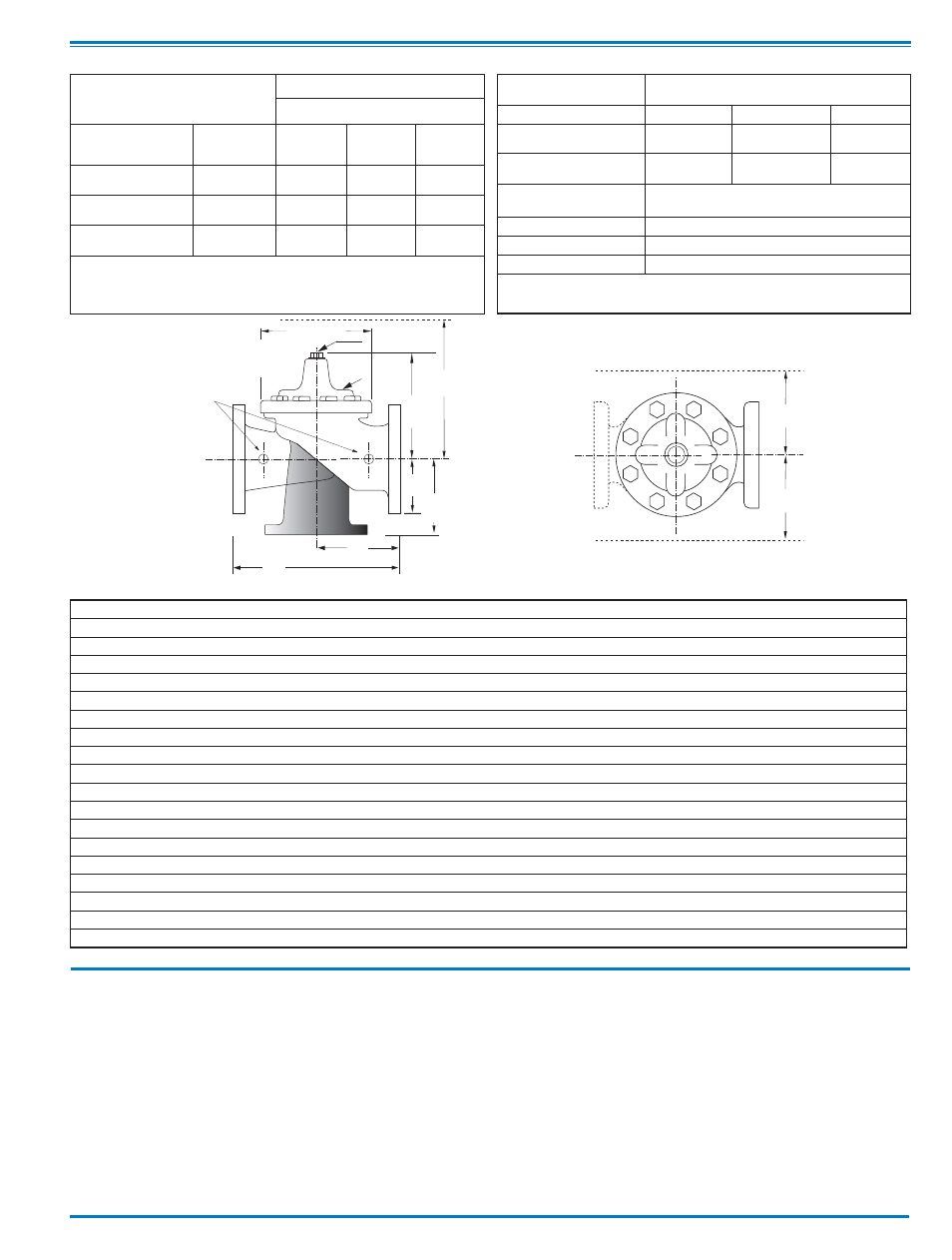

Model 3650-01 Dimensions

(In Inches)

Materials

EE

D

E

Inlet

DD

AA

X

100-20

Flanged

F

A

C

(MAX)

K

J

H

Inlet

Outlet

FF

B

(Diameter)

Dimensions

(In inches)

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Cast Steel

Bronze

Available Sizes

3" - 48"

3" - 16"

3" - 16"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is Optional

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Y

Z

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Body & Cover

Pressure Class

Flanged

Grade

Material

ANSI

Standards*

150

Class

300

Class

ASTM A536

Ductile Iron

B16.42

250

400

ASTM A216-WCB

Cast Steel

B16.5

285

400

ASTM B62

Bronze

B16.24

225

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Valves for higher pressure are available; consult factory for details

Note: The top two flange holes on valve sizes 36 thru 48 are threaded to 1 1/2"-6 UNC.

*Consult Factory

Valve Size

(Inches)

3

4

6

8

10

12

14

16

18

20

24

30

36

42

48

A 150 ANSI

10.25

13.88

17.75

21.38

26.00

30.00

34.25

35.00

42.12

48.00

48.00

63.25

65.00

76.00

94.50

AA 300 ANSI

11.00

14.50

18.62

22.38

27.38

31.50

35.75

36.62

43.63

49.62

49.75

63.75

67.00

76.00

94.50

B Dia.

6.62

9.12

11.50

15.75

20.00

23.62

27.47

28.00

35.44

35.44

35.44

53.19

56.00

66.00

66.00

C Max.

7.00

8.62

11.62

15.00

17.88

21.00

20.88

25.75

25.00

31.00

31.00

43.94

54.60

61.50

61.50

D 150 ANSI

—

6.94

8.88

10.69

CF*

CF*

CF*

CF*

CF*

CF*

CF*

—

—

—

—

DD 300 ANSI

—

7.25

9.38

11.19

CF*

CF*

CF*

CF*

CF*

CF*

CF*

—

—

—

—

E 150 ANSI

—

5.50

6.75

7.25

CF*

CF*

CF*

CF*

CF*

CF*

CF*

—

—

—

—

EE 300 ANSI

—

5.81

7.25

7.75

CF*

CF*

CF*

CF*

CF*

CF*

CF*

—

—

—

—

F 150 ANSI

3.75

4.50

5.50

6.75

8.00

9.50

11.00

11.75

15.88

14.56

17.00

19.88

25.50

28.00

31.50

FF 300 ANSI

4.12

5.00

6.25

7.50

8.75

10.25

11.50

12.75

15.88

16.06

19.00

22.00

27.50

28.00

31.50

H NPT Body Tapping

.375

.50

.75

.75

1

1

1

1

1

1

1

1

2

2

2

J NPT Cover Center Plug

.50

.50

.75

.75

1

1

1.25

1.25

2

2

2

2

2

2

2

K NPT Cover Tapping

.375

.50

.75

.75

1

1

1

1

1

1

1

1

2

2

2

Stem Travel

0.6

0.8

1.1

1.7

2.3

2.8

3.4

3.4

3.4

4.5

4.5

6.5

7.5

8.5

8.5

Approx. Ship Wt. Lbs.

45

85

195

330

625

900

1250

1380

1500

2551

2733

6500

8545

12450 13100

X Pilot System

13

15

27

30

33

36

36

41

40

46

55

68

79

85

86

Y Pilot System

10

11

18

20

22

24

26

26

30

30

30

39

40

45

47

Z Pilot System

10

11

18

20

22

24

26

26

30

30

30

39

42

47

49