Model – Cla-Val 350-01/3650-01 User Manual

Page 5

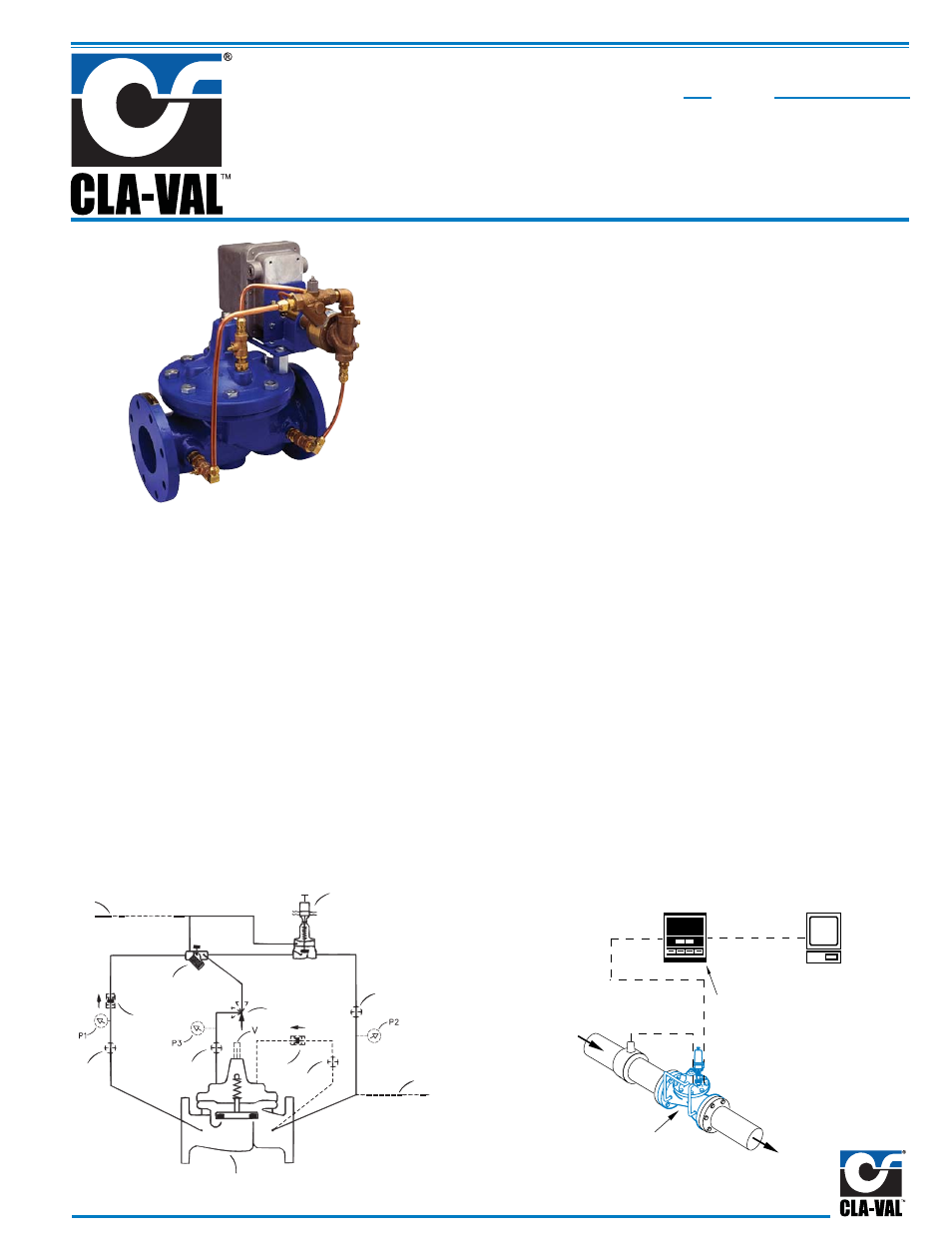

Typical Applications

Schematic Diagram

Item Description

1

Hytrol (Main Valve)

2

X42N-2 Strainer & Needle Valve

3

CRL-30 Electronic Pressure Sustaining Control

Optional Features

Item Description

B

CK2 (Isolation Valve)

D

Check Valves with Isolation Valve

F

Remote Pilot Sensing

H Drain

to

Atmosphere

P

X141 Pressure Gauge

S

CV Flow Control (Opening)

V

X101 Valve Position Indicator

•

Simplified Interfacing with SCADA Systems

•

Accepts Local or Remote Set-Point

•

Integral Loop Power Supply

•

Accurate Pressure Control

•

Reliable Hydraulic Operation

•

Rugged Durable Design

The Cla-Val Model 350-01/3650-01 Electronic Actuated Pressure Sustaining

Control Valve combines the precise control of field proven Cla-Val hydraulic

pilots and the convenience and versatility of remote Set-Point control. The

Model 350-01/3650-01 control valve is a hydraulically operated, pilot controlled,

modulating valve designed to maintain constant upstream pressure within

close limits. This valve can be used for pressure sustaining, back pressure,

or unloading functions in a by-pass system. The pilot control, consisting of a

hydraulic pilot and integral controller, accepts a Set-Point and compares it

with a pressure or internal potentiometer signal and makes incremental

adjustments to modulate the valve to a Set-Point.

Adjustable solid state limit switches eliminate over ranging. In the event of a

power or transmitter failure, the CRL-30 pilot remains in hydraulic control

virtually assuring system stability under changing conditions. If check

feature ("D") is added, and pressure reversal occurs, the valve closes to

prevent return flow.

Electronic Actuated

Pressure Sustaining Control Valve

RTU

Area Of Demand

Remote Set Point

Remote Telemetry Unit

(Customer Supplied)

Upper Zone

Process

Variable

Upstream

Pressure

CLA-VAL

350-01/3650-01

Electronic Actuated

Pressure Sustaining Valve

SCADA

Computer

F

D1

B1

2

S

B1

D2

D3

B2

3

1

INLET

OUTLET

H

DRAIN TO

ATMOSPHERE

Remote Sensing

The valve is designed to be used with supervisory control systems having

a isolated remote analog Set-Point output and a process variable

upstream pressure input. When installed in a line between an upper zone

and a lower area of demand, the valve acts to maintain desired upstream

pressure to prevent "robbing" of the upper zone. Water in excess of pressure

setting flows to area of demand, control is smooth, and pressure regula-

tion is positive.

It is also an effective solution for lowering costs associated with "confined

space" requirements by eliminating need for entry into valve structure for

Set-Point adjustments and system information.

Additional Pilot Controls, hydraulic and/or electronic, can be easily added

to perform multiple control functions to fit exact system requirements.

350-01

MODEL

(Full Internal Port)

3650-01

(Reduced Internal Port)