Cla-val, 01ko, When ordering, please specify – Cla-Val 90-01KO User Manual

Page 8: Pilot system specifications

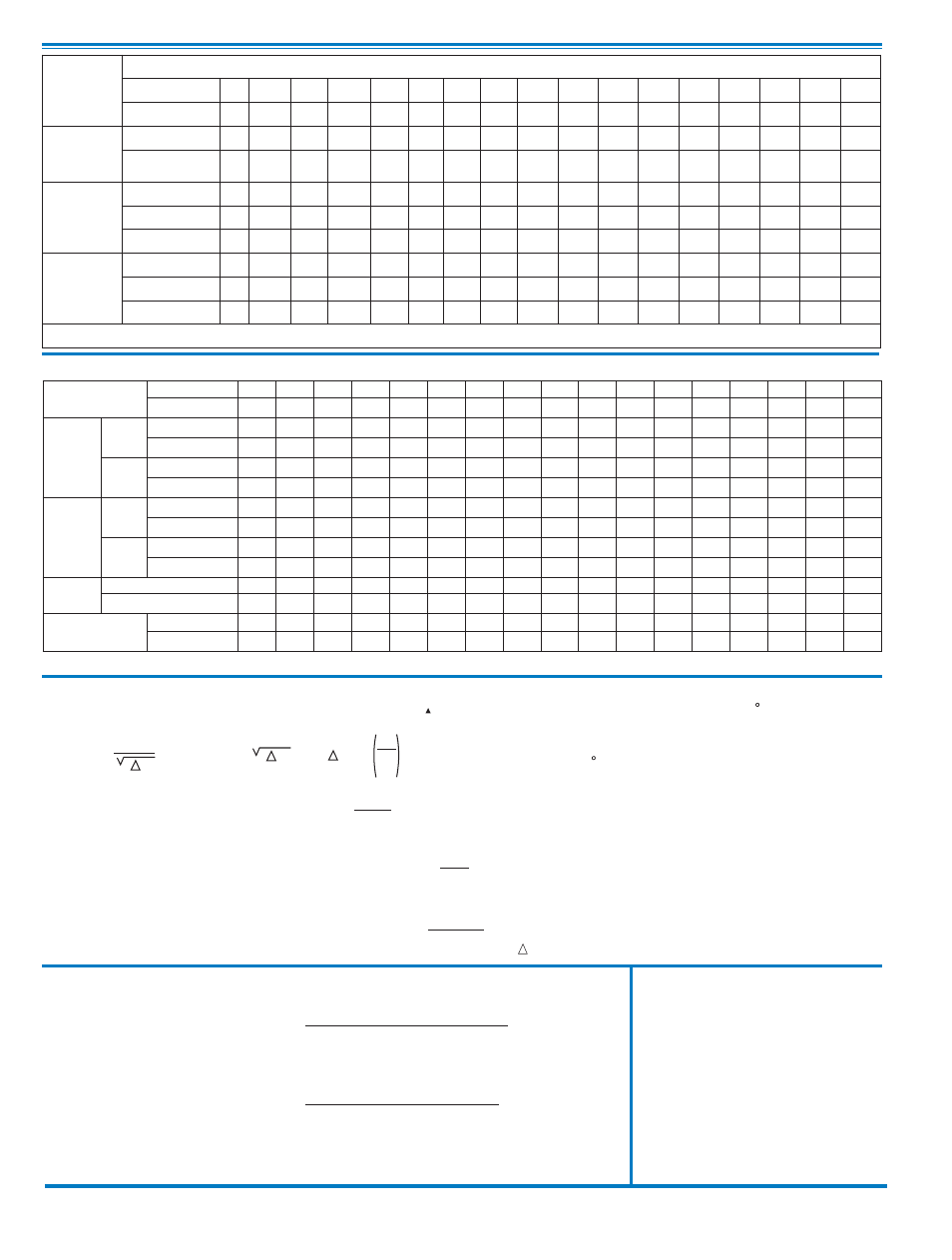

Functional Data

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

E-90-01KO (R-7/2011)

For assistance in selecting appropriate valve options or valves manufactured with special design requirements, please contact our Regional Sales Office or Factory.

K =

894d

4

C

2

v

L =

K

12 f

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

d

V =

.4085 Q

2

d

C

V

Factor

Formulas for computing C Factor, Flow (Q) and Pressure Drop

V

( P):

C

V

=

Q

P

C

V

=

Q

P

C

V

=

Q

P

2

V

Where:

U.S. (gpm) @ 1 psi differential at 60 F water

(l/s) @ 1 bar (14.5 PSIG) differential

or

at 15 C water

inside pipe diameter of Schedule 40 Steel Pipe (inches)

friction factor for clean, new Schedule 40 pipe

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

Equivalent Length of Pipe (feet)

Flow Rate in U.S. (gpm) or (l/s)

Fluid Velocity (feet per second) or (meters per second)

Pressure Drop in (psi) or (bar)

=

=

=

=

=

=

=

=

=

P

V

Q

L

K

f

d

C

Valve Size

Inches

1

1

⁄

4

1

1

⁄

2

2

2

1

⁄

2

3

4

6

8

10

12

14

16

18

20

24

30

36

mm.

32

40

50

65

80

100

150

200

250

300

350

400

450

500

600

750

900

C

V

Factor

Globe

Pattern

Gal./Min. (gpm.)

14

14

25

37

52

90

218

362

660

810

1100 1200 1550 1950 3900 6100 9150

Litres/Sec. (l/s.)

3.4

3.4

6.0

8.9

12.5

21.6

52

87

159

194

264

288

360

469

938

1466 2199

Angle

Pattern

Gal./Min. (gpm.)

15

15

26

39

55

95

232

388

479

790

1075 1175

—

—

—

—

—

Litres/Sec. (l/s.)

3.6

3.6

6.2

9.4

13.2

22.8

56

93

115

190

258

282

—

—

—

—

—

Equivalent

Length of

Pipe

Globe

Pattern

Feet (ft.)

196

196

237

277

416

572

858

1315 2444 2118 1937 3022 3537 4199 4532 3897 3954

Meters (m.)

60

60

72

84

127

174

262

401

745

646

590

921

1078 1280 1381 1188 1205

Angle

Pattern

Feet (ft.)

171

171

219

250

372

514

757

1145 2133 2226 2021 3152

—

—

—

—

—

Meters (m.)

52

52

67

76

113

157

231

349

650

678

616

961

—

—

—

—

—

K Factor

Globe Pattern

30.6

30.6

26.1

24.3

29.3

29.0

25.5

27.7

41.0

27.7

22.8

31.4

30.2

29.5

28.9

17.6

15.1

Angle Pattern

26.7

26.7

24.1

21.8

26.2

26.0

22.5

24.1

35.8

29.1

23.8

32.8

—

—

—

—

—

Liquid Displaced from

Cover Chamber When

Valve Opens

U.S. Gal.

0.2

0.2

.03

.04

.08

.17

.53

1.26

2.5

4.0

6.5

9.6

11

12

29

65

90

Litres

0.8

0.8

.12

.16

.30

.64

2.0

4.8

9.5

15.1

25.6

36.2

41.6

45.4

110

246

340

Adjustment Ranges

2

to

30 psi

15 to

75

psi

20

to

105 psi

30

to 300 psi*

*Supplied unless otherwise specified

Other ranges available, please consult factory

Temperature Range

Water: to 180°F

Materials

Standard Pilot System Materials

Pilot Control: Bronze ASTM B62

Trim: Stainless Steel Type 303

Rubber: Buna-N

®

Synthetic Rubber

Optional Pilot System Materials

Pilot Systems are available with optional

Aluminum, Stainless Steel or Monel materials.

Note: Available with remote sensing control.

When Ordering, Please Specify

1. Catalog No. 90-01KO

2. Valve Size

3. Pattern - Globe or Angle

4. Pressure Class

5. Threaded, Flanged or Grooved End

6. Trim Material

7. Adjustment Range

8. Desired Options

9. When Vertically Installed

Pilot System Specifications

90-01KO

Valve

Selection

100-01KO Pattern:

Globe (G), Angle (A),

End Connections:

Threaded (T), Grooved (GR), Flanged (F) Indicate Available Sizes

Inches

1

1

⁄

4

1

1

⁄

2

2

2

1

⁄

2

3

4

6

8

10

12

14

16

18

20

24

30

36

mm

32

40

50

65

80

100

150

200

250

300

350

400

450

500

600

750

900

Basic Valve

100-01KO

Pattern

G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A

G

G

G, A

G

G

End Detail

T

T, F,

Gr*

T, F,

Gr

T, F,

Gr*

T, F,

Gr

F,

Gr

F,

Gr*

F,

Gr*

F

F

F

F

F

F

F

F

F

Suggested

Flow

(gpm)

Max. Continuous

84

115

190

270

410

710

1620 2810 4420

6280

7590

9920 12550 14900 22600 37700 52450

Max. Intermittent

120

160

260

370

580

990

2250 3900 6150

8720 10540 13700 17500 21700 31300 48000 62500

Min. Continuous

10

10

15

20

30

50

115

200

300

400

500

650

560

1073

1577

2650

3150

Suggested

Flow

(Liters/Sec)

Max. Continuous

5.3

7.3

12

17

26

45

102

177

279

397

479

694

792

940

1427

2379

3309

Max. Intermittent

7.6

10

16

23

37

62

142

246

387

549

664

863

1104

1369

1972

3028

3940

Min. Continuous

.6

.6

.9

1.3

1.9

3.2

7.2

13

19

25

32

41

41

57

110

132

180

100-01KO Series is the full internal port Hytrol.

For Lower Flows Consult Factory

*

Globe Grooved Only