Dimensions, Materials, Pressure ratings – Cla-Val 133-11/633-11 User Manual

Page 2

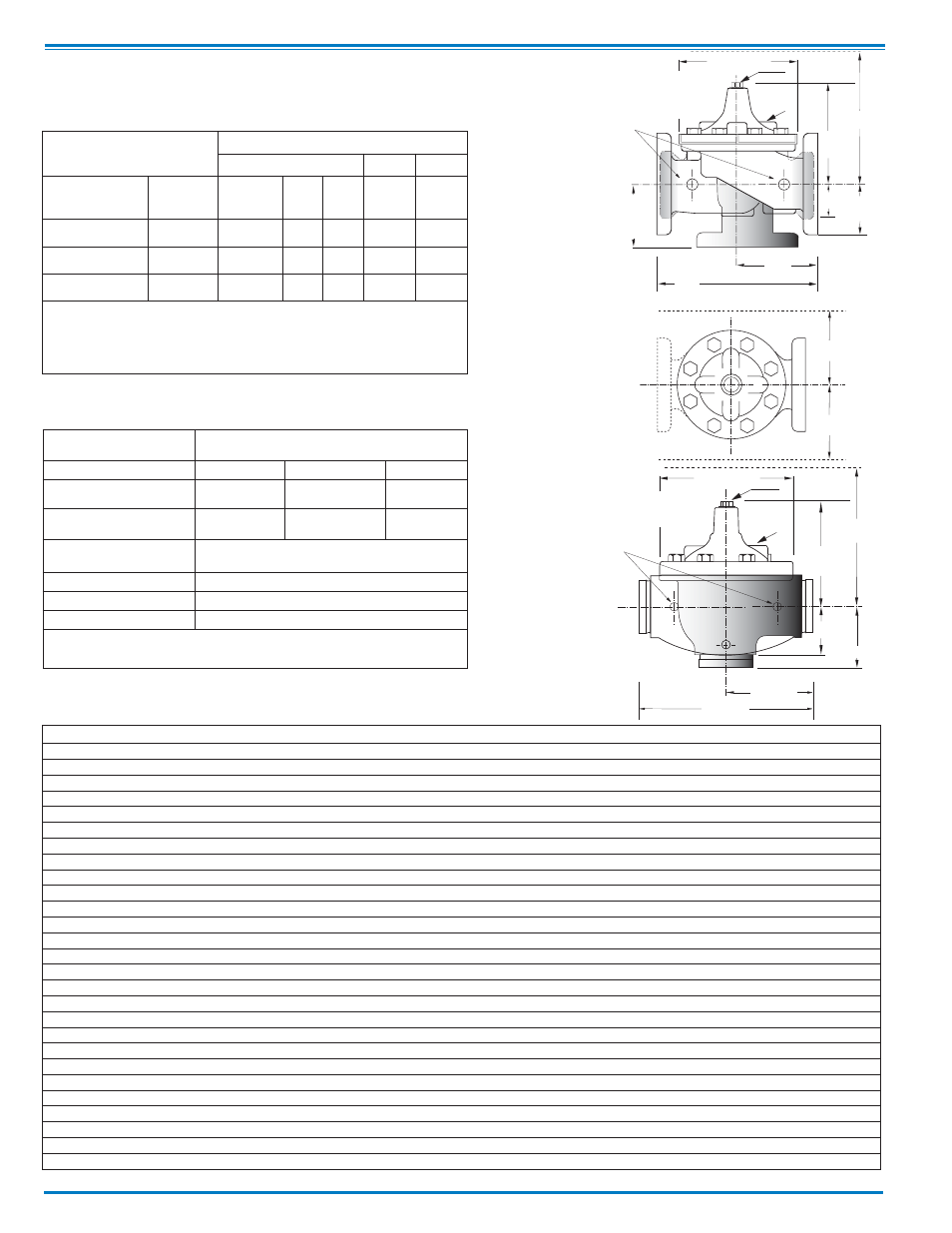

Model 133-11

(Uses Basic Valve Model 100-01)

Model 133-11 Dimensions

(In Inches)

Note: The top two flange holes on valve size 36 are threaded to 1 1/2"-6 UNC.

Dimensions

(In inches)

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Cast Steel

Bronze

Available Sizes

3" - 36"

3" - 16"

3" - 16"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is Optional

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

GGGG

DDDD

Inlet

AAAA

X

100-01

Grooved

EE

CC

(MAX)

K

J

H

Inlet

Outlet

B

(Diameter)

Y

Z

G

GG

GGG

D

Inlet

DD

DDD

F

FF

X

100-01

Threaded &

Flanged

A

E

C

(MAX)

K

J

H

Inlet

Outlet

AA

AAA

B

(Diameter)

Valve Body & Cover

Pressure Class

Flanged

Grooved Threaded

Grade

Material

ANSI

Standards*

150

Class

300

Class

300

Class

End‡

Details

ASTM A536

Ductile Iron B16.42

250

400

400

400

ASTM A216-WCB Cast Steel

B16.5

285

400

400

400

ASTM B62

Bronze

B16.24

225

400

400

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Size (Inches)

3

4

6

8

10

12

14

16

18

20

24

30

36

A Threaded

12.50

—

—

—

—

—

—

—

—

—

—

—

—

AA 150 ANSI

12.00

15.00

20.00

25.38

29.75

34.00

39.00

41.38

46.00

52.00

61.50

63.00

76.00

AAA 300 ANSI

13.25

15.62

21.00

26.38

31.12

35.50

40.50

43.50

47.64

53.62

63.24

64.50

76.00

AAAA Grooved End

12.50

15.00

20.00

25.38

—

—

—

—

—

—

—

—

—

B Dia.

9.12

11.50

15.75

20.00

23.62

28.00

32.75

35.50

41.50

45.00

53.16

56.00

66.00

C Max.

8.19

10.62

13.38

16.00

17.12

20.88

24.19

25.00

39.06

41.90

43.93

54.60

61.50

CC Max. Grooved End

7.25

9.31

12.12

14.62

—

—

—

—

—

—

—

—

—

D Threaded

6.25

—

—

—

—

—

—

—

—

—

—

—

—

DD 150 ANSI

6.00

7.50

10.00

12.69

14.88

17.00

19.50

20.81

—

—

30.75

—

—

DDD 300 ANSI

6.38

7.88

10.50

13.25

15.56

17.75

20.25

21.62

—

—

31.62

—

—

DDDD Grooved End

6.00

7.50

—

—

—

—

—

—

—

—

—

—

—

E

2.06

3.19

4.31

5.31

9.25

10.75

12.62

15.50

12.95

15.00

17.75

21.31

24.56

EE Grooved End

3.12

4.25

6.00

7.56

—

—

—

—

—

—

—

—

—

F 150 ANSI

3.75

4.50

5.50

6.75

8.00

9.50

10.50

11.75

15.00

16.50

19.25

22.50

25.60

FF 300 ANSI

4.13

5.00

6.25

7.50

8.75

10.25

11.50

12.75

15.00

16.50

19.25

24.00

25.60

G Threaded

4.50

—

—

—

—

—

—

—

—

—

—

—

—

GG 150 ANSI

4.00

5.00

6.00

8.00

8.62

13.75

14.88

15.69

—

—

22.06

—

—

GGG 300 ANSI

4.38

5.31

6.50

8.50

9.31

14.50

15.62

16.50

—

—

22.90

—

—

GGGG Grooved End

4.25

5.00

—

—

—

—

—

—

—

—

—

—

—

H NPT Body Tapping

.50

.75

.75

1

1

1

1

1

1

1

1

2

2

J NPT Cover

Center Plug

.50

.75

.75

1

1

1.25

1.5

2

1.5

1.5

1.5

2

2

K NPT Cover Tapping

.50

.75

.75

1

1

1

1

1

1

1

1

2

2

Stem Travel

0.8

1.1

1.7

2.3

2.8

3.4

4.0

4.5

5.1

5.63

6.75

7.5

8.5

Approx. Ship Wt. Lbs.

70

140

285

500

780

1165

1600

2265

2982

3900

6200

7703

11720

X Pilot System

15

17

29

31

33

36

40

40

43

47

68

79

85

Y Pilot System

11

12

20

22

24

26

29

30

32

34

39

40

45

Z Pilot System

11

12

20

22

24

26

29

30

32

34

39

42

47