Cla-Val 133-11/633-11 User Manual

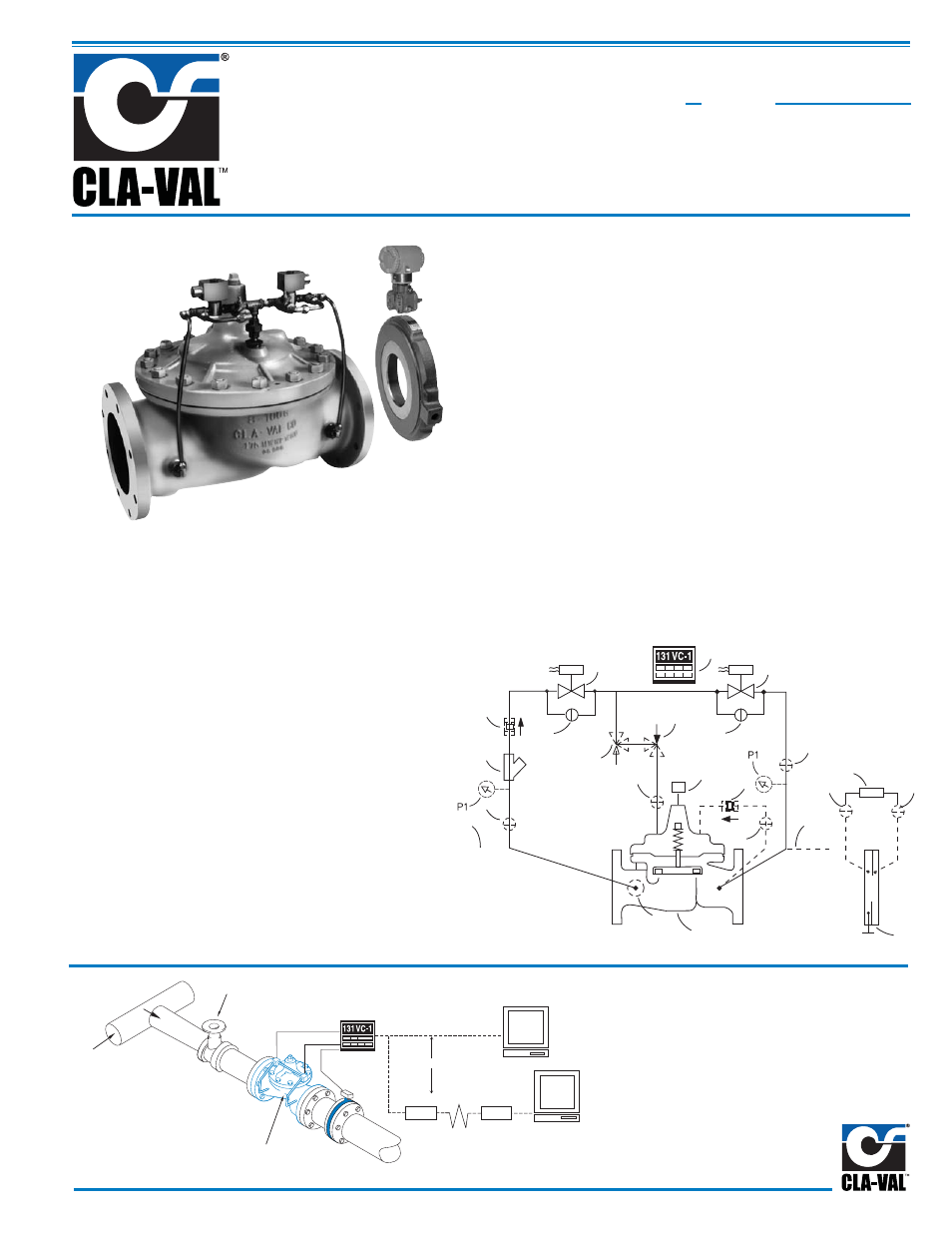

Metering & flow rate control valve, Model, Schematic diagram

133-11

MODEL

(Full Internal Port)

633-11

(Reduced Internal Port)

6

B

B

DPT

H

D2

D3

E

D1

Y

3A

2A

CS2

B

S

C

A

CS2

2B

4

B

3B

DRAIN TO

ATMOSPHERE

9

F

INDEPENDENT

OPERATING

PRESSURE

INLET

OUTLET

5

1

Main Transmission

Line

Isolating Valve

133-11/633-11

Metering & Flow Rate Controller

131VC-1 Electronic

Valve Controller

To Optional Remote

Computer Control (Local)

Computer

Computer

SCADA

To Optional Remote Control

Modem

Modem

DPT

Schematic Diagram

Item Description

1

Hytrol (Main Valve)

2

CS2S Solenoid Control

3

CK2 Solenoid By-Pass

4

131VC-1 Electronic Control

5

X52D-1 Orifice Plate Assembly

6

DPT Differential Pressure Transmitter

Optional Features

Item Description

A

X46A Flow Clean Strainer

B

CK2 (Isolation Valve)

C

CV Flow Control (Closing)

D

Check Valve with Isolation Valve

E

X117D Position Transmitter

F

Independent Operation Pressure

H

Atmospheric Drain

P

X141 Pressure Gauge

S

CV Flow Control (Opening)

Y

X43 "Y" Strainer

Metering & Flow Rate Control Valve

•

Automatically Maintains Flow Rate

•

Up to 10:1 Flow Range Control

•

Ideal For SCADA Systems

•

Digital or Analog Communications

•

Retransmission Capabilities

•

Security System to Prevents Unauthorized Changes

•

Optional Hydraulic Backup Pilot Control System

The Model 133-11/633-11 Metering and Flow Rate Control Valve accu-

rately meters and maintains flow rate regardless of changing system con-

ditions. It is an electrically operated, electronically directed, hydraulically

actuated diaphragm valve. Included is 131VC-1 Electronic Valve Controller

Microprocessor that responds to differential pressure produced across a

calibrated orifice plate or venturi. Accurate control is assured as very small

changes in the differential produce immediate corrective action in the main

valve. Differential Pressure Transmitter is recallable to suite flow range

requirements.

The Model 133-11/633-11 Metering and Flow Rate Control Valve can also

be configured to perform a wide variety of secondary functions when

combined with hydraulic pilot operation, such as: pressure reducing, pres-

sure sustaining and level control. Any of these functions can be used in

conjunction with electronic control or to provide a separate automatic fail-

safe operation through the use of backup hydraulic pilot systems.

Typical Applications

The 133-11/633-11 is typically installed in

a fluid delivery system where the flow rate

is measured and changed from a remote

location such as a SCADA system

.