Piping, When installing the pump below the tank, When installing the pump above the tank – Pump Solutions Group Neptune Solenoid-driven Diaphragm Metering Pump ARPZ-31_61_12 User Manual

Page 12: Installation

11

Installation

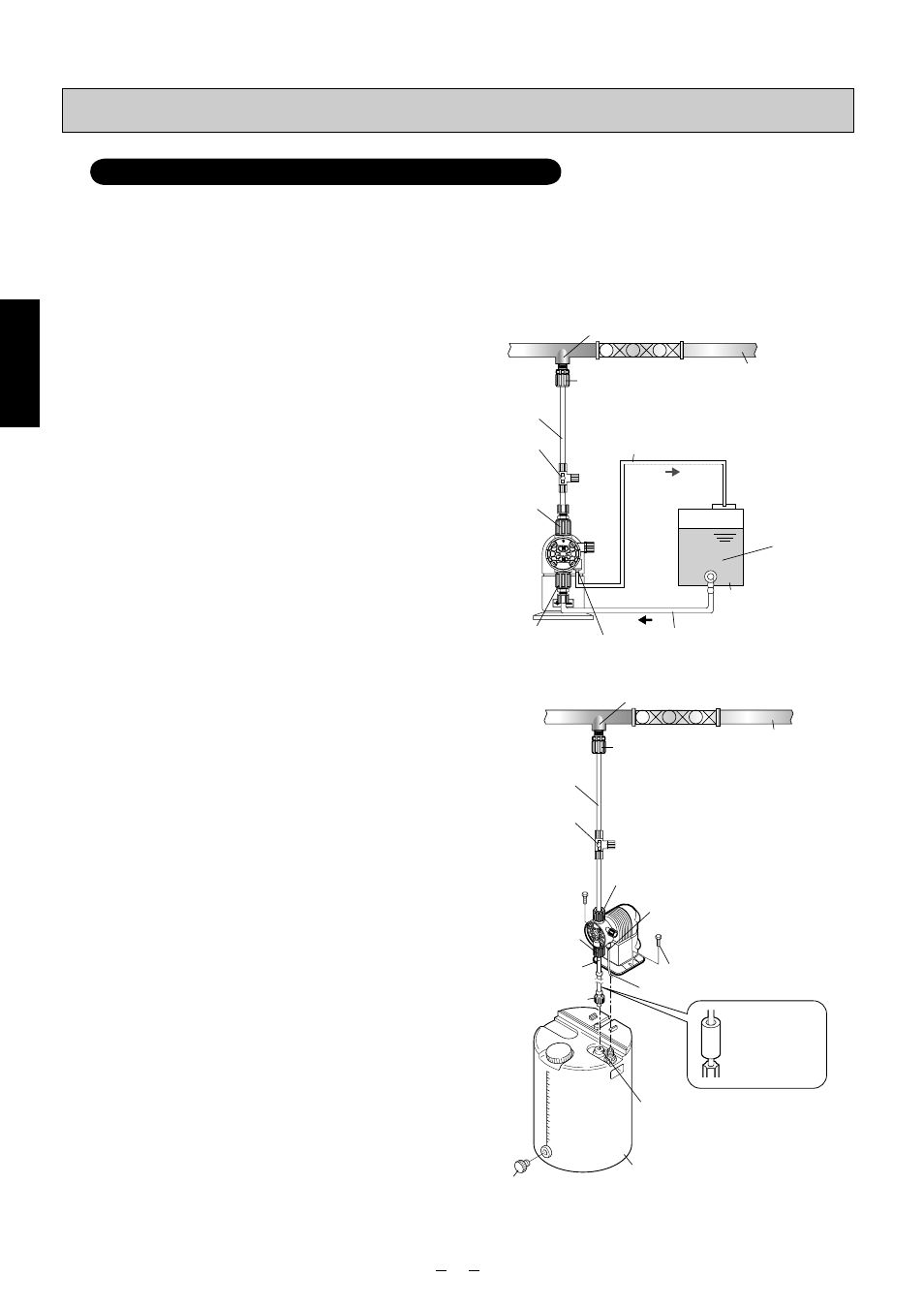

Pump-mounting bolts (2 sets)

Foot valve

Drain cock

Suction-pipe cover

Tank

Relief/air-release hose

Discharge-side joint

Suction-side joint

Suction-side pipe

Relief/air-release port

Main pipe

Anti-siphon check valve

Attach the ceramic

weight (supplied) to

straighten the tube.

Discharge-

side pipe

Injection point

3-way valve

PVDF

U P

Discharge-

side pipe

Discharge-

side joint

Suction-side joint

Suction-side pipe

Suction valve

Injection point

Relief/air-release port

3-way valve

Main pipe

Anti-siphon check valve

Relief/air-release hose

Tank

Installation is described with an example using PZ-31-FEC (PP) and TACMINA tank.

• If the valve has not been opened or clogging by foreign matter has occurred inside the pipe at the discharge side of

the pump, the chemical will gush out from the relief/air-release port. Therefore, always have a relief/air-release hose

installed, and lead its end back into the tank or other container.

• Install a valve for releasing abnormal pressure that has built up inside the discharge-side pipe. The 3-way valve on the

washing water line may be used instead.

Piping

Model for injection of boiler chemicals: PZ-31-FEC (PP)

■ When installing the pump

below the tank

(1) Connect the suction valve of the tank and the suction-

side joint of the pump using the tube.

(2) Connect the discharge-side joint of the pump and

main pipe (injection point) using the tube. When

doing this, attach the anti-siphon check valve at the

injection-point side end of the tube.

(3) Return the end of the relief/air-release hose which

has already been attached to the relief/air-release

port to the tank or other container.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

■ When installing the pump

above the tank

(1) Using the pump-mounting bolts provided, secure the

pump to the prescribed position on top of the tank.

(2) Pass the suction-side tube with foot valve and

ceramic weight attached through the hole in the

suction-pipe cover on top of the tank, and connect

it to the suction-side joint of the pump. At this time,

adjust the length of the tube and cut it so that the

foot valve is 30 mm higher than the bottom of the

tank.

(3) Connect the discharge-side joint of the pump and

main pipe (injection point) using the tube. When

doing this, attach the anti-siphon check valve at the

injection-point side end of the tube.

(4) Return the end of the relief/air-release hose which

has already been attached to the relief/air-release

port to the tank or other container.

✽ Installing the pump above the tank is not recommend-

ed for chemicals in which air bubbles tend to form.

✽ This pump’s static suction head is −1.5 m for water.

Its suction capability may decrease when the valve

seats inside the pump head are dry.

✽ Be absolutely sure to connect the foot valve provided

to the end of the suction-side hose to prevent dirt

or foreign matter from entering the pump head and

valve seat area.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

07-22_PZ総合取説_E.indd 11

07-22_PZ総合取説_E.indd 11

2008/02/13 8:50:54

2008/02/13 8:50:54