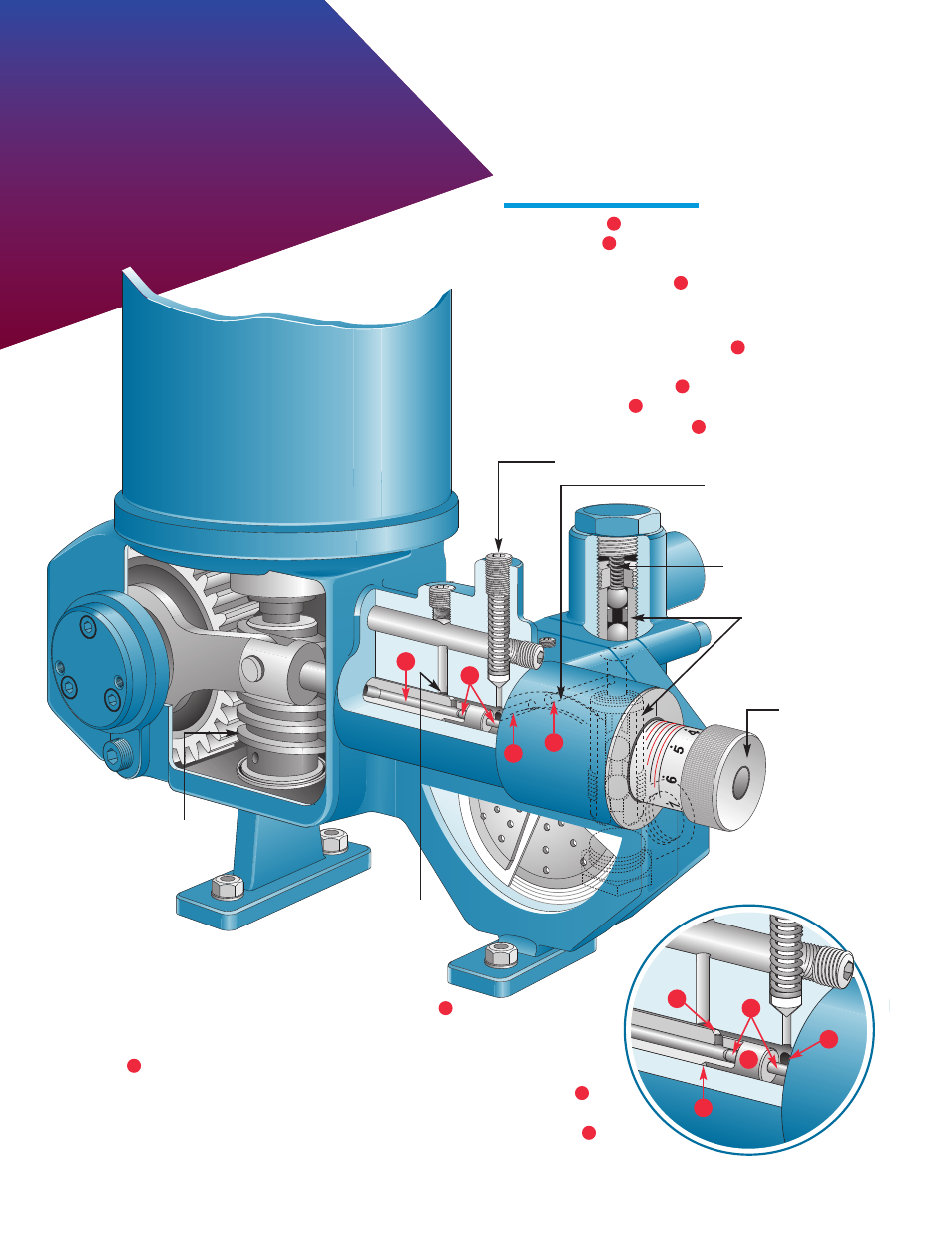

Pump Solutions Group Neptune Series 500 dia-PUMP How It Works User Manual

Neptune series 500 “dia-pump, How it works, The only pumps with eze-clean

2

Variable Oil By-pass

TM

stroke adjustment allows

better valve performance than variable linkage

designs. The valve checks have extra time to

seat even in heavy liquids since they are idle

during the by-pass portion of the suction

and discharge strokes.

How It Works

Hollow piston

reciprocates within a cylinder.

Metering rod

fits into the piston. Note the front

of the piston, or “nose”, has a reduced diameter.

The liquid seal forms at

where the full diameter

of the piston contacts the cylinder.

When the piston moves forward, oil by-passes over

the reduced nose, through port

to the center of

the piston and back to the gearbox. As the piston

continues forward, port

is blocked by the tip of

the metering rod

stopping the by-pass. Oil is

now pushed through port

to the diaphragm.

Neptune

Series 500

“dia-PUMP”

The only pumps with

EZE-CLEAN

TM

Valves

Hydraulically balanced Teflon

®

diaphragm eliminates diaphragm

stress associated with mechani-

cally flexed units.

EZE-CLEAN

TM

Valves—

Cartridges can be removed

for cleaning without

disturbing the piping

to the pump.

Adjustable while

running through

100% of range by

micrometer dial.

Internal relief valve protects pump and motor.

Antisiphon spring provides

back pressure when pumping

against low pressure.

Vent—Refill mechanism

operates once per stroke.

Power train

operates in oil for

extended service.

Turning the micrometer dial moves the metering rod

and changes the pump capacity. When the metering

rod is moved in, the tip of the metering rod closes port

sooner in the stroke allowing for less by-pass and more pumping action.

Likewise, when the metering rod is moved out, the tip of the metering rod

closes port

later in the stroke allowing more by-pass and less pumping.

The motion of the piston pushes and pulls the hydraulic fluid through port

,

into and out of the diaphragm chamber. The action of the fluid pushes and

pulls the diaphragm which, in turn, pushes and pulls chemical through port

.

The action of the check valves controls the direction of the liquid.

1

2

5

6

1

2

3

4

5

4

4

1

2

3

4

4

2

5

6

5