Pump Solutions Group Neptune Series 500 MODEL 481 THRU 547 User Manual

Page 8

5

1.0.11

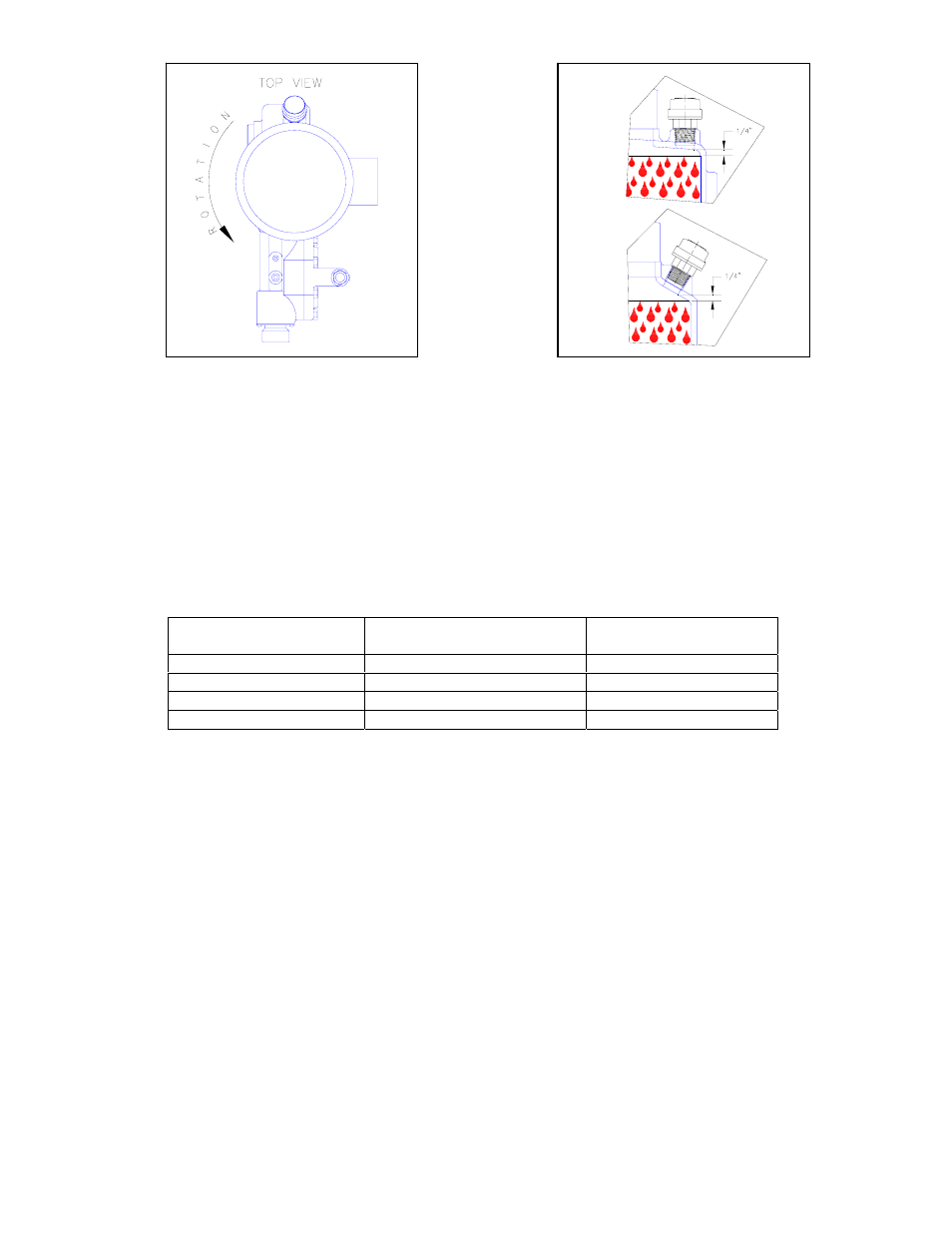

Set capacity knob to zero and remove Air Bleed Plug from the top of Oil Chamber, refer to drawings HP-1102 (page 21)

for Series 500 and drawing 5024 (page 27) for Series 500-A and 500-E for location of plug. Fill gear box and pump by

pouring the hydraulic fluid supplied through the fill opening at the rear of the pump. Pour fluid in slowly until it has

reached the correct level per Figure 1A. Do not over fill as this can cause damage to the motor.

Allow a few minutes for the hydraulic fluid work through the oil head and appear at the oil bleed plug. Recheck oil level.

When air is purged, reinstall the Air Bleed Plug.

The hydraulic fluid supplied by Neptune is:

EP 68 Gear Oil, Scot Lubricants, 1801 E. Tremont Street, P.O. Box 326, Allentown, PA 18105

Information: 610-433-2527

Heavier hydraulic fluid is supplied by Neptune for Hi Pressure Systems is EP SAE 90.

The 90 weight gear oil is used for high-pressure pumps using 1/2 horsepower motors or larger and rated for operation

over 1000 PSI.

The 90-weight gear oil is also provided for the 481, 500, and 501 pump models at all pressures.

2.0

SUCTION PIPING

2.0.1

The suction piping to the pump must be absolutely air tight. It is suggested that the suction piping be tested with

low air pressure and a soap solution to assure that no leaks exist.

2.0.2

NEPTUNE RECOMMENDS THAT THE ‘‘dia-Pump’’ BE OPERATED WITH A FLOODED SUCTION, AS THIS

WILL FACILITATE START UP AND INCREASE THE SERVICE LIFE OF THE PUMP. It is, however, possible to

operate the ‘‘dia-Pump’’ with a suction lift of up to 5 feet, if absolutely necessary. A FOOT VALVE STRAINER

must be used on this type of application. Model 481 and 501 require a flooded suction.

2.0.3

It is highly recommended that all solution tanks be furnished with a low level cut off switch or low level alarm and

cut off switch to prevent the pump from running dry. OPERATION AGAINST A DRY SYSTEM WILL CAUSE

DAMAGE TO THE PUMP DIAPHRAGM AND REDUCE THE OPERATING LIFE OF THE PUMP.

2.0.4

The single, safest rule of thumb for selecting suction pipe size is to use the same size or one size larger than

the pump suction connection (1/2” pipe minimum).

Alternate

Oils For Standard

Mfg. Alternate

High Pressure Oils

Omala #68

Shell Oil

Omala #220

Mobil Gear #626

Mobil Oil

Mobil Gear #629

Sun EP #68

Sun Oil

Sun Oil #220

Meropa #68

Texaco

Meropa #220

FIGURE 1A

FIGURE 1

OIL LEVEL.DWG