Ssttaarrttuupp pprreeccaauuttiioonnss, Bblloowweerr ssttaarrttuupp – Spencer 4BOB Multistage Centrifugal Blowers User Manual

Page 7

77

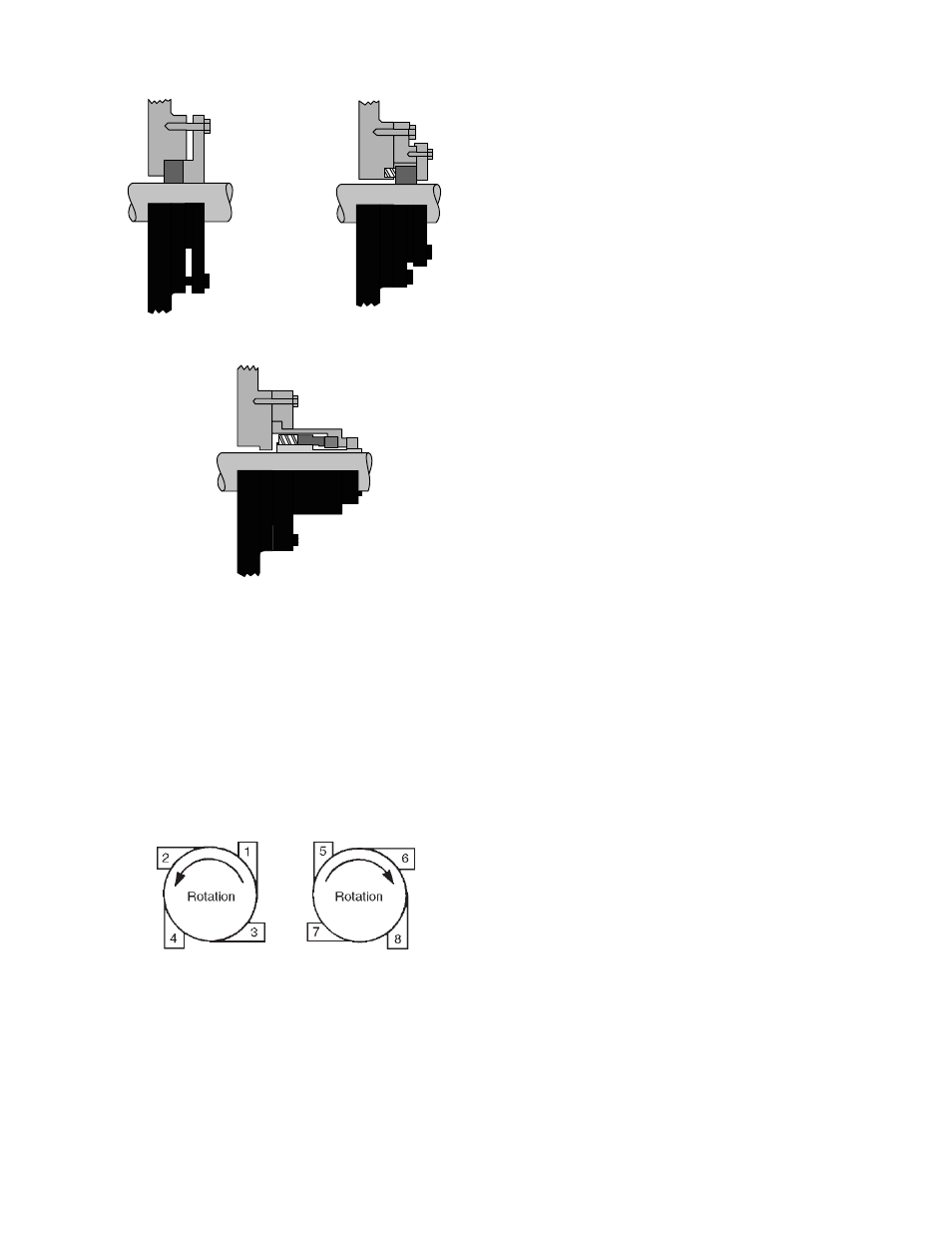

88.. SShhaafftt SSeeaallss ((44BBO

OBB BBlloowweerrss && G

Gaass

BBoooosstteerrss))

Shaft seals at both the inlet and discharge ends minimize leakage

of gas into or out of the blower. Packing boxes are standard for

4BOB blowers. Packing boxes, carbon ring seals and mechanical

seals may be used on gas boosters. Consult Spencer Form DD

or applicable manufacturerʼs instructions.

99.. M

Moottoorr RRoottaattiioonn

The motor must be wired correctly to rotate the blower in the

right direction. A rotation arrow is located on the blower housing.

“Bump” or jog the start button and observe the direction of rotation

of the motor shaft. This movement must agree with the rotation

arrow. If the rotation is incorrect, the motor wiring must be

changed.

This diagram shows the available discharge positions, viewed

from the intake end, and the direction of blower rotation associated

with each discharge position.

VVII.. O

Oppeerraattiioonn aanndd

AAddjjuussttm

meennttss

SSttaarrttuupp PPrreeccaauuttiioonnss

Before operating a new blower for the first time, review its

installation and setup to be sure that no steps have been over-

looked.

11.. IInnssttaallllaattiioonn CChheecckk LLiisstt

• Is there any damage from transportation or installation?

• Is the machine level?

• Have all packing, shipping materials and tools been removed?

• Is the inlet filter in place?

• Are isolation pads in place?

• Is the piping connected and supported?

• Are flexible connectors in place between blower and piping?

• Are safety guards in place?

22.. AAddjjuussttm

meenntt CChheecckkss

• Is the coupling aligned within tolerances and lubricated?

(4BOB & 4BOH blowers only)

33.. O

Oppeerraattiioonnaall CChheecckkss

• Is the throttling valve closed or properly positioned?

• Do the blower shaft and driver spin freely?

• Is the isolation valve (if any) open?

• Is the system ready for air or gas delivery?

• Has motor rotation been checked?

• Are motor and electrical accessories properly wired?

• Is the control panel energized?

• Have maintenance and operations personnel been notified?

CCAAUUTTIIO

ONN:: TThhiiss bblloowweerr m

muusstt hhaavvee aaddeeqquuaattee ssyysstteem

m rreessiiss--

ttaannccee aatt aallll ttiim

meess ttoo aavvooiidd ooppeerraattiioonn aatt oorr nneeaarr ffrreeee ddeelliivveerryy

((wwiiddee ooppeenn)).. IItt iiss ttyyppiiccaallllyy iim

mppoosseedd bbyy tthhee pprroocceessss aanndd

ssuupppplleem

meenntteedd wwiitthh aa tthhrroottttlliinngg vvaallvvee.. RRuunnnniinngg tthhee bblloowweerr

oovveerrllooaaddeedd wwiillll ddaam

maaggee tthhee m

moottoorr..

BBlloowweerr SSttaarrttuupp

With the system connected and the throttling valve closed, turn

the blower on. Quickly assess the current draw of the motor.

Adjust the system load or throttling valve until the desired flow

is reached, being careful not to operate in surge or to exceed

the full-rated motor capacity. Initially, blowers will temporarily

develop more differential pressure and take more power. Check

final settings after operating temperature is achieved, typically

after one-half hour. If the throttling valve is not fully open when

the motor capacity has been reached, it should be fixed at this

point to prevent further opening and possible overloading of the

motor.

Packing Box

Carbon Ring

Mechanical Seal