Iivv.. hhaannddlliinngg aanndd ssttoorraaggee, Lliiffttiinngg aanndd m moovviinngg, Ssttoorraaggee – Spencer 4BOB Multistage Centrifugal Blowers User Manual

Page 4: Uunnppaacckkiinngg, Llooccaattiioonn, Ffoouunnddaattiioonn, Bblloowweerr sseettuupp

44

IIVV.. HHaannddlliinngg aanndd

SSttoorraaggee

Each Spencer blower is carefully balanced and tested at the

factory. For optimum performance, it must be handled with care

during unloading and installation.

Check the shipment for damage upon arrival; file any claims

with the shipper and notify Spencer.

LLiiffttiinngg aanndd M

Moovviinngg

Moving of this equipment is the customerʼs responsibility and

should be performed or directed by experienced riggers using

accepted rigging practices and safety precautions. The blower/

motor assembly can be lifted and relocated with a forklift, over-

head crane or hoist. Always use lifting equipment rated for the

loads involved.

CCAAUUTTIIO

ONN:: DDoo nnoott lliifftt tthhee bblloowweerr bbyy iittss sshhaafftt oorr bbeeaarriinngg

hhoouussiinngg;; uussee tthhee ffuurrnniisshheedd lliiffttiinngg eeyyeess oorr sslloottss iinn tthhee

bblloowweerr bbaassee..

SSttoorraaggee

If a blower is stored for an extended period before use or

between uses, protect it from dampness, dirt and vibration.

Suspend bags of silica gel desiccant in the inlet and discharge.

Cover the entire blower if possible or at least cover the inlet and

discharge openings to keep out foreign matter. Rotate the blow-

er shaft a few times by hand every week, keeping a log.

CCAAUUTTIIO

ONN:: FFaaiilluurree ttoo ccoom

mppllyy wwiitthh tthhee rreeqquuiirreedd ssttoorraaggee

pprroovviissiioonnss,, iinncclluuddiinngg wweeeekkllyy sshhaafftt rroottaattiioonnss,, wwiillll vvooiidd tthhee

wwaarrrraannttyy..

UUnnppaacckkiinngg

1. Uncrate the blower, saving all literature, boxes and parts.

2. Remove inlet and discharge protective caps and all packing

materials.

3. Use the packing slip to check off and confirm the presence

of all ordered components.

4. Read any instructional and warning labels on the machine

before installation and operation.

VV.. IInnssttaallllaattiioonn

NOTE: If any problems are encountered during installation or

startup, consult your local Spencer Representative.

LLooccaattiioonn

CCAAUUTTIIO

ONN:: DDoo nnoott llooccaattee bblloowweerr oorr ccoonnttrroollss wwhheerree tthheeyy wwiillll

bbee ssuubbjjeecctt ttoo aam

mbbiieenntt tteem

mppeerraattuurreess aabboovvee 110044°°FF ((4400°°CC))

dduurriinngg ooppeerraattiioonn,, uunnlleessss ssppeecciiaallllyy eeqquuiippppeedd ffoorr hhiigghheerr

tteem

mppeerraattuurreess..

Spencer blowers may be installed outdoors, preferably under

cover, or indoors. When choosing an indoor location, be sure

there is sufficient ventilation to allow unrestricted airflow to the

blower. In addition, it is advisable to leave several feet of space

around the blower and motor for ease of servicing. Inaccessibility

can prove costly.

Consideration should be given to the noise generated by this

equipment and its contribution to the ambient noise level.

Optional noise reduction accessories include blower housing

sound attenuation jackets, filter silencers or silencers for the

blower inlet and/or discharge, and silencers for the motor.

NOTE: Duct noise attenuation is a customer responsibility.

FFoouunnddaattiioonn

A level concrete pad is recommended, although any flat level

surface that can support the machine weight is satisfactory. The

blower base should be placed level on the furnished isolation

pads or equivalent. Each pad must be shimmed, if necessary,

to ensure that it is carrying its share of the load. If lag bolts and

nuts are used to restrain the blower, hand-tighten only.

NOTE: Spencer does not recommend grouting of machines.

BBlloowweerr SSeettuupp

CCAAUUTTIIO

ONN:: M

Maakkee ssuurree bblloowweerr iinnlleett aanndd ddiisscchhaarrggee ppoorrttss aarree

uunnoobbssttrruucctteedd bbeeffoorree ccoonnnneeccttiinngg ppiippiinngg ttoo bblloowweerr..

11.. PPiippiinngg

All piping connected to the blower should be of ample size to

minimize frictional loss. All system joints must be airtight; leaky

pipes waste air and power.

All piping must be properly aligned and supported to avoid

stress on the blower and restrained to prevent movement away

from the blower caused by air pressure. Flexible connectors

must be used to connect piping to the blower.

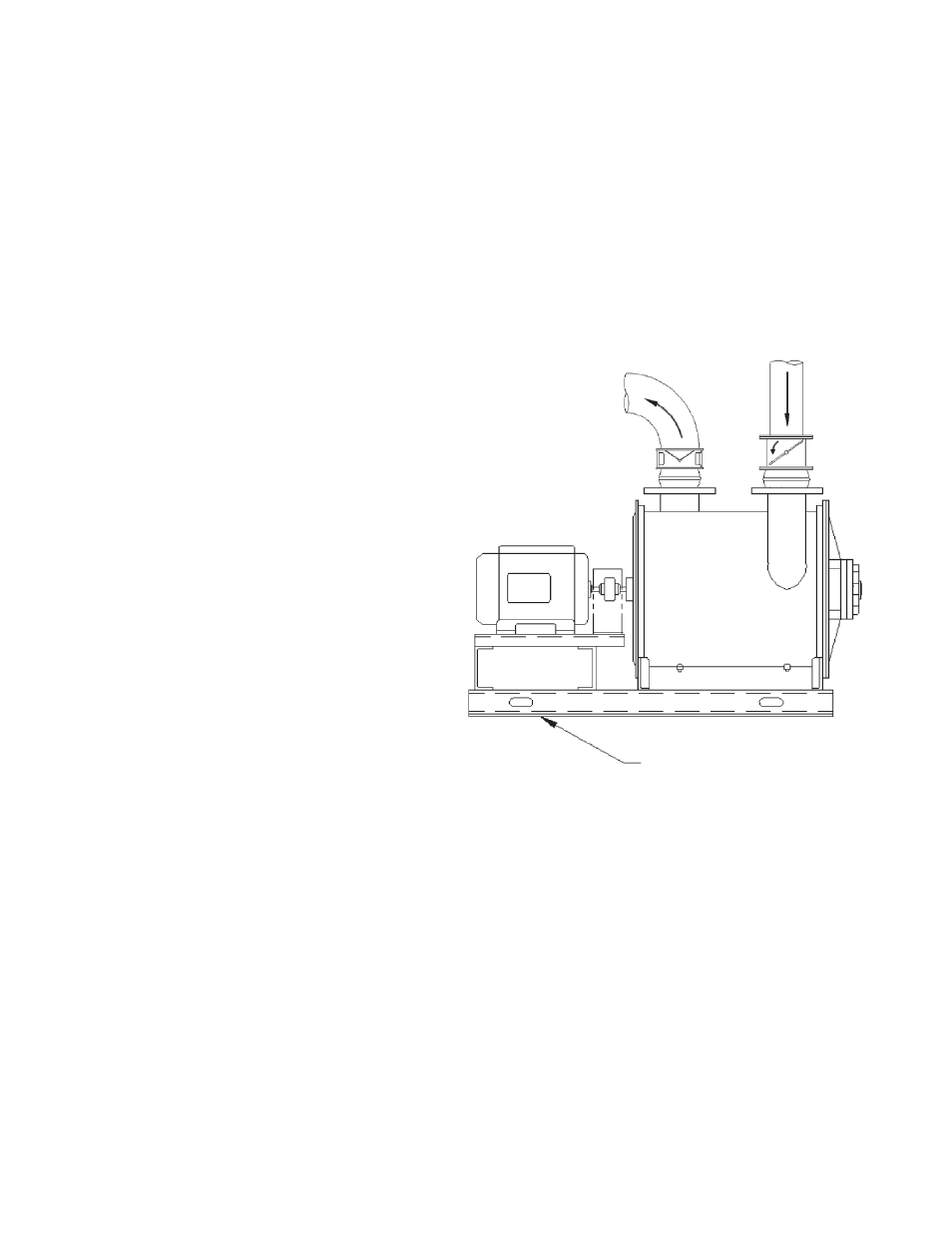

NOTE: The diagram above shows the proper orientation of a

piping elbow in-line with the blower shaft. The butterfly valve

should have its shaft at right angles to the blower shaft and the

valve should open as indicated (counterclockwise in this exam-

ple). These steps will assure uniform loading of the blowerʼs

first stage.

11"" IIssoollaattiioonn PPaadd

(shim if necessary)

IInnlleett

DDiisscchhaarrggee

CChheecckk

VVaallvvee

FFlleexxiibbllee

CCoonnnneeccttoorrss

BBuutttteerrffllyy

VVaallvvee