Bell & Gossett V1000187C Circuit Setter Plus Calibrated Balance Valves – Lead-Free User Manual

Page 5

4. If Loctite 567 is unavailable, we recommend Rector Seal No. 5 pipe thread sealant for all non-glycol based

applications, or any PTFE thread sealing tape. Be sure to follow the manufacturer specific handling precautions and

application instructions as noted on the product labeling.

5. Thread component into valve until it is finger tight.

6. Apply torque to the following specification:

Any field adjustment of factory installed components will break the original thread seal and could cause leakage. This

will necessitate the removal, cleaning, and resealing of those parts per the instructions below.

Should any adjustment or servicing of P/T readout ports or drain plugs be required, please take the following steps:

1. Completely remove the desired component from the valve.

2. Taking care not to damage any threads on the component or the valve, clean off all of the old thread sealant. Use

a wire brush and gentle abrasion if necessary. Allow the valve and the component to dry. Note: If the component or

valve appears to have been damaged, replace it.

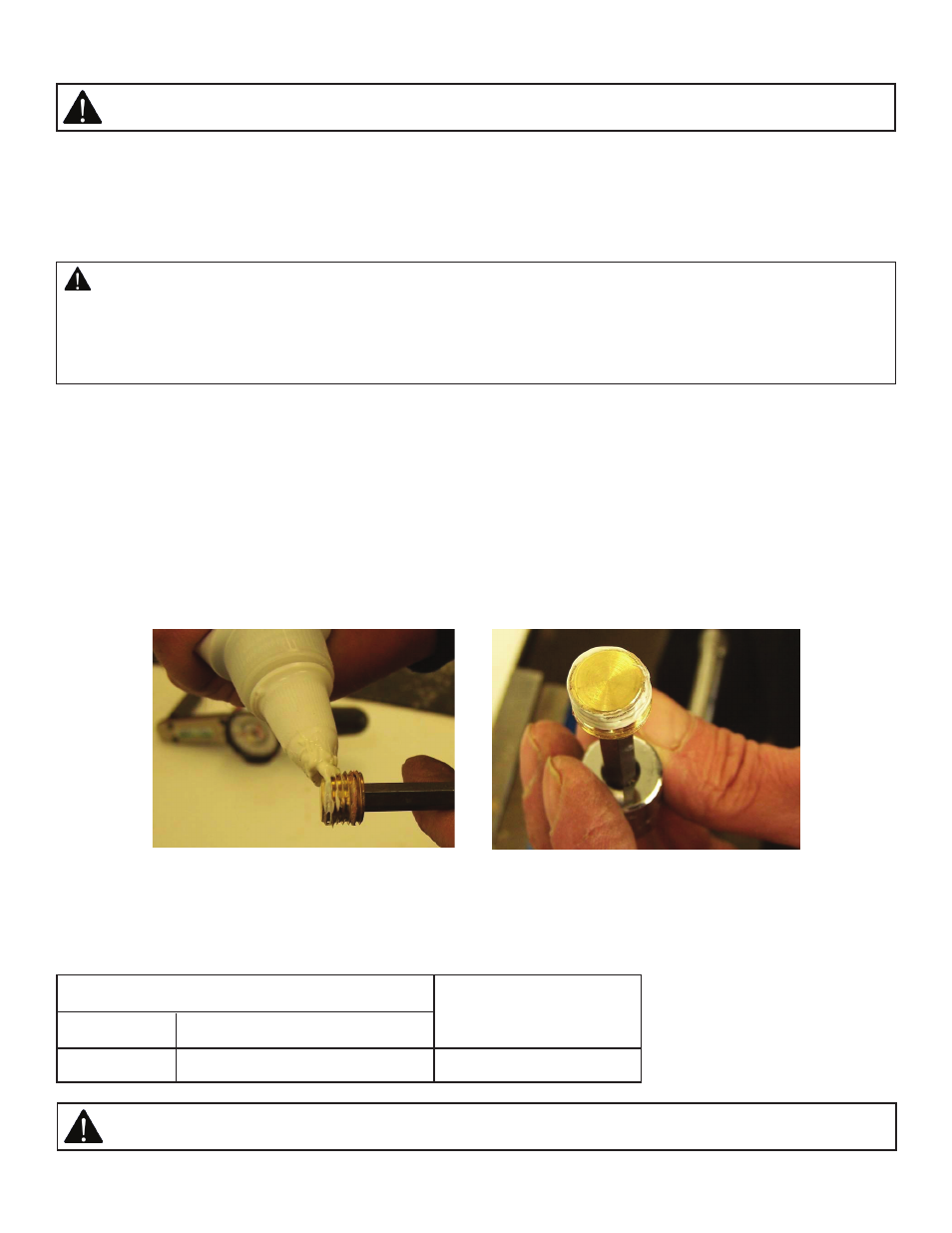

3. Starting with the second thread of the NPT male valve component, apply a 360° bead of Loctite 567 thread sealant/

lubricant as shown below. Follow Loctite handling precautions as noted on the product labeling.

NOTICE: The use of thread sealants/lubricants on threads also provides lubricity. Over application of torque

may cause damage to the valve port or component.

Component

Torque

Size

Type

1/4” NPT

P/T Readout Port, Drain Plug

9.0 ft.-lbs + 3.0 ft.-lbs. / -0

Service Instructions

Periodically inspect the Circuit Setter for signs of leakage or corrosion.

The P/T readout ports and drain plugs found on Bell & Gossett Circuit Setter Plus calibrated balance valves come

pre-assembled with a leading industrial thread sealant, Loctite 567, and are tightened to appropriate levels. P/T readout

ports on Sweat model Circuit Setters are shipped loose and will need to be installed as per the instructions below. With

that in mind, the following information should help to clarify questions regarding the adjustment or servicing of those

components when required.

WARNING: Corrosion or leakage are indications that the Circuit Setter must be replaced. Failure to follow

these instructions could result in serious personal injury or death and property damage.

WARNING: Installation and maintenance must be performed by a qualified professional. Service should not be

performed on any valve in an active Hydronic loop. Before attempting to make any required adjustments,

properly isolate and drain the branch loops that require service and allow the valves to reach a safe handling

temperature and zero pressure condition. Use proper safety equipment including gloves, goggles, or similar

tools to avoid contact with system fluids and common hazards. Failure to follow these instructions could result

in personal injury and property damage.