Bell & Gossett S12596B Technologic 350 Pump Controller User Manual

Page 7

7

1.8

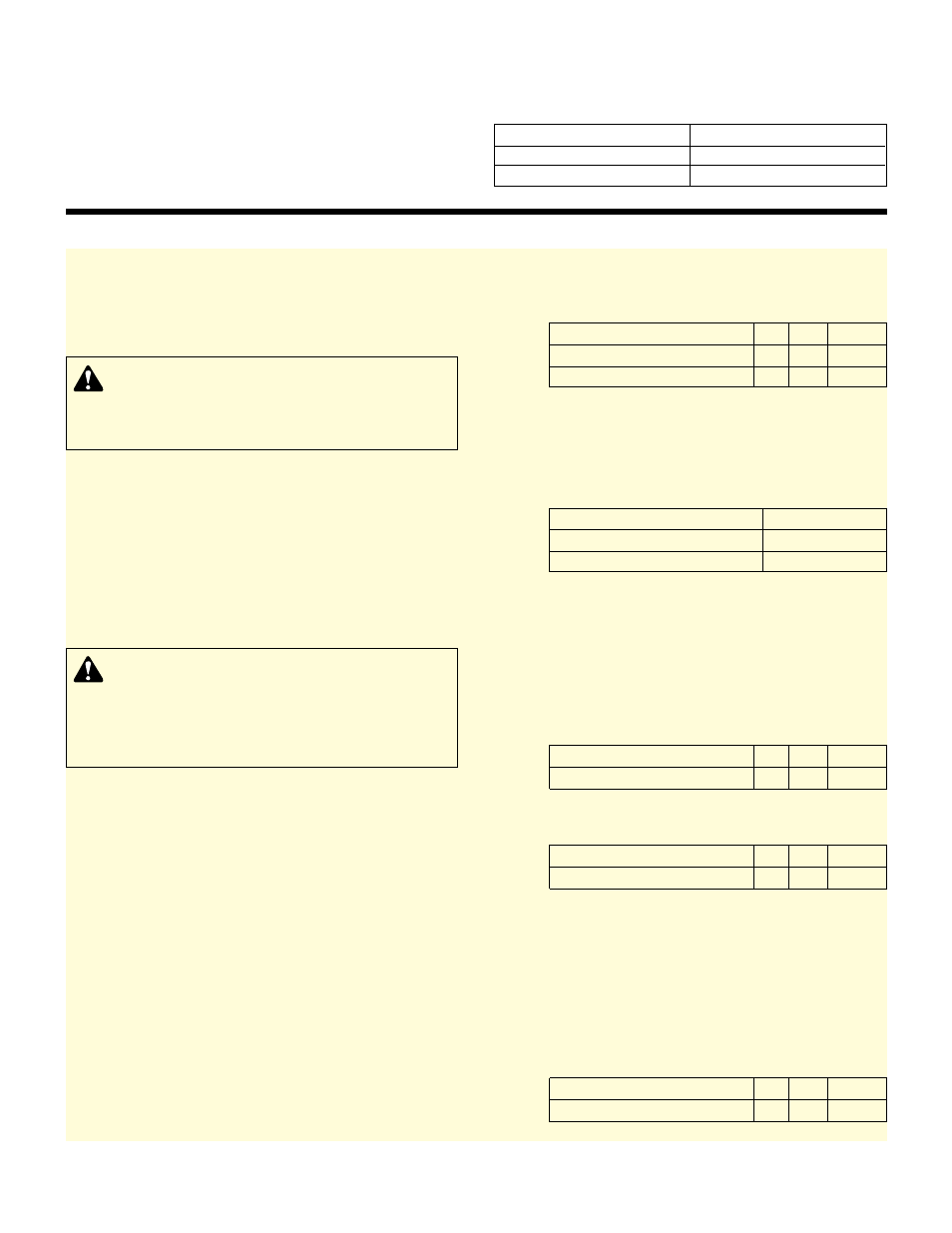

FIELD CONNECTION DIAGRAMS

1.8.1

Refer to the pump Installation, Opreation, and mainte-

nance Manual for specific details unique to the pump.

1.8.2

Refer to the flow sensor/transmitter Installation,

Operation, and Maintenance Manual for specific

details unique to the flow sensor/transmitter.

1.8.3

The following field connection diagrams should be

reviewed prior to unit installation and operation.

Drawing #

Description

Job Specific Print(s)

Wiring Diagram(s)

Job Specific Print

Dimensional Drawings

2.0

LOCATION

2.1

Locate the Technologic Controller so that it will be

easily accessible for inspection, maintenance and

service.

2.2

INSTALLATION

This unit is built to give you years of service; install it

properly and provide a suitable foundation. (Check

the shipping ticket for unit weight.) Mount the unit to

provide a rigid connection that will not move or shift

under any circumstance.

2.3

LEVELING

Mount the unit on a level surface and check that it is

plumb on all sides.

2.4

WIRING

2.4.1

POWER WIRING

The Technologic 350 control panel can be set up to

operate across a broad range of voltages. It was fac-

tory set to operate on the voltage shown on the name-

plate. Verify proper transformer primary wiring per the

job-specific wiring diagram. Check power leads in

accordance with wiring diagram enclosed in control

cabinet. The voltage tolerance is +10%/-10%.

2.4.2

ANALOG SIGNAL WIRING

If installing the panel on an existing system, shielded

cable (#22 AWG, Belden type 8762, Alpha #2411 or

equal) should be installed for the DC control wiring.

The shield must be terminated in the Technologic 350

control panel. Do not connect the shield at the other

end of the cable! Insulate the shield so that no electri-

cal connection is made at the other end of the cable.

A twisted pair of #22 AWG conductors (Belden 8442

or equal) can be used in place of shielded cable. The

cable length must be limited to 3000 feet for #22

AWG wire.

2.4.2.1

PRESSURE TRANSMITTER WIRING

(Optional) (4-20mA Analog Signals)

Terminals (J3)

+

-

Shield

1PT Pressure Transmitter

3

2

4

2PT Pressure Transmitter

3

6

4

2.4.2.2

TEMPERATURE SENSOR WIRING

(Optional) (Analog Resistance Input)

The Tech 350 uses resistance temperature detectors

(RTDs) to sense the T-1 and T-2 water temperatures.

These devices change their resistance as the water

temperature changes.

Temperature Sensor (RTD) Wiring

Terminals (J3)

T-1 Low Temperature Sensor

13, 14

T-2 High Temperature Sensor

16, 17

2.4.2.3

FLOW SENSOR/TRANSMITTER WIRING

AND INSTALLATION

(Optional) (4-20mA Analog Signal)

The flow sensor should be installed at an angle no

greater than 45 degrees from top dead center in a

horizontal installation (see Manufacturer’s IOM). See

the Bell & Gossett drawing for installation instructions.

The signal wiring should be terminated in the Tech

350 panel at the terminals below.

Optional Flow Sensor/Transmitter (1FT)

+

-

Shield

Terminals (J3)

9

8

10

2.4.2.4

TEMPERATURE TRANSMITTER WIRING

(Optional) (4-20mA Analog Signal)

Terminal J3

+

-

Shield

AI-4 Temperature Transmitter

9

12

10

2.4.3

DIGITAL SIGNAL WIRING

2.4.3.1

DIFFERENTIAL PRESSURE SWITCH

PIPING AND WIRING

(Optional) (Digital Signal)

Differential pressure switches installed to sense the

increase in pressure between the pump suction and

discharge gauge taps are used to determine whether

a pump is running. Each switch should be wired from

the normally closed contact to the terminals below.

Pump #

1

2

3

Terminal (J4)

9, 8 10, 11

11, 12

SECTION 2 – INSTALLATION

DANGER: Heavy load, may drop if not lifted properly.

Do not lift the entire unit by the motor eyebolts. Lift

the unit with slings placed under the unit base rails.

Failure to follow these instructions could result in seri-

ous personal injury, death, and/or property damage.

DANGER: Electrical shock hazard. Inspect all electri-

cal connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices.

Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.