Bell & Gossett S12596B Technologic 350 Pump Controller User Manual

Page 13

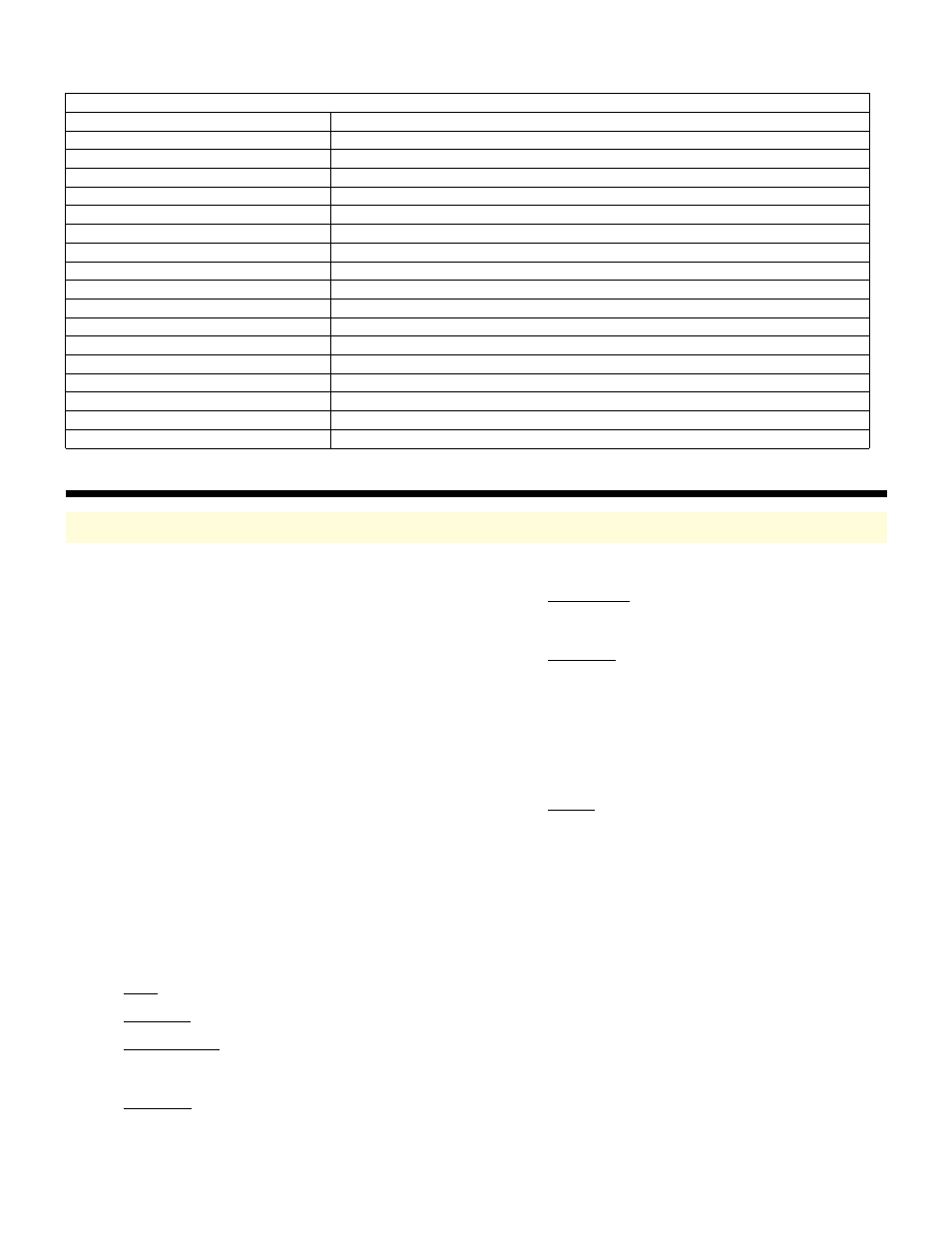

ALARMS

CONDITION

HELP MESSAGE

Overload X Failure

Check AMP draw, use manual reset if OK

High 1PT PSI

High suction pressure - check suction pressure and trip point

Low 1PT PSI

Low suction detected - check suction pressure and trip point

High 2PT PSI

High pressure detected in the system - check trip point

Low 2PT PSI

Low pressure detected in the system - check PRV and set point

Water Temp High

Check water temperature

Pump X Off

Need pump in system - if OK enable pump

1PT Fail

Check wiring, piping, polarity, and continuity

2PT Fail

Check wiring, piping, polarity, and continuity

AI-4 Fail

Check wiring, piping and continuity

1FT Fail

Check wiring, piping, polarity, and continuity

T-1 Fail

Check wiring, continuity

T-2 Fail

Check wiring, continuity

Power Board Fail

Check cable connections and plug insertions

Pump X Failure

Check DP switch, impeller, coupler, motor

Remote Contact Open

➀

7 Day Timer Off

➀

Notes:

➀

Bottom line only. No help message.

4.5.2

ALARMS

13

SECTION 5 – OPERATION

5.1

POWER UP

5.11

Initial – turn selector switch to local or remote with

power on.

5.1.2

Message Scroll

A. “Booting”

B. “Bell & Gossett”

“Pressure Booster”

C. “Technologic 350”

“Pump Controller”

D. “Copyright 1995”

“Fluid Handling Division”

E. “FW Release VX.XX”

“Serial # XXXXX”

F. Normal Scroll per 4.5 commences

5.1.3

Set Up and System Configuration. User Menu.

A. Press the SETUP key. Enter the serial number

followed by the ENTER key.

B. Press the UP or DOWN arrow key to step through

user menu of paragraph 4.3.2. To change any

value press ENTER, modify the default value using

the numeric key pad, and then press ENTER to

load. Press CLEAR to exit menu.

5.2

AUTO OPERATION

5.2.1

Local (turn selector switch to local or remote).

5.2.2

Auto/Hand – select Auto.

5.2.3

Enable/Pump/s by pressing 1, 2 or 3 PUMP ENABLE

keys according to number of pumps in menu. Green

LED’s flash.

5.2.4

Start/Stop – Press START/STOP key momentarily.

Green LED is on. Note: Only if selector switch is

turned to local or remote and at least 1 pump is

enabled. Message: Top Line – see below. Bottom

Line – “start up standby”.

5.2.5

Pump Start – The first pump in the alternation

sequence starts and LED turns to solid green. Only 1

pump is on.

5.2.6

Alternation – If the alternation key is pressed the next

pump in sequence starts and both pumps then run for

5 seconds at which time the first pump stops. During

alternation: Top line – normal scroll. Bottom line – “Alt.

Engaged standby”.

If Alternation Timer picks up the action is the same as

above provided an entry other than 0 is made in the

user menu.

5.2.7

Staging – According to the method of staging selected

in the user menu, i.e., HP, AMPs, PSI, GPM, Temp

and Delta T the 2nd pump in the alternation sequence

will turn on when:

1. HP matches % stage value

or

2. AMP value matches % stage value

or

3. GPM value matches % stage value

or

4. Pressure matches PSI stage value

or

5. Temp matches temp stage value

The third pump in the alternation sequence turns on

similarly.

Staging will not occur if:

1. High 1PT alarm is on.

2. Low 1PT alarm is on.

3. High T-2 alarm is on.

4. High 2PT alarm is on.

5. Timed de-stage is on.

6. Starter feedback is not on.

The 3rd pump stages in the same manner as the sec-

ond pump according to the menu entry for that pump.