Bell & Gossett V51019 ISO-FLO Accessories User Manual

Page 2

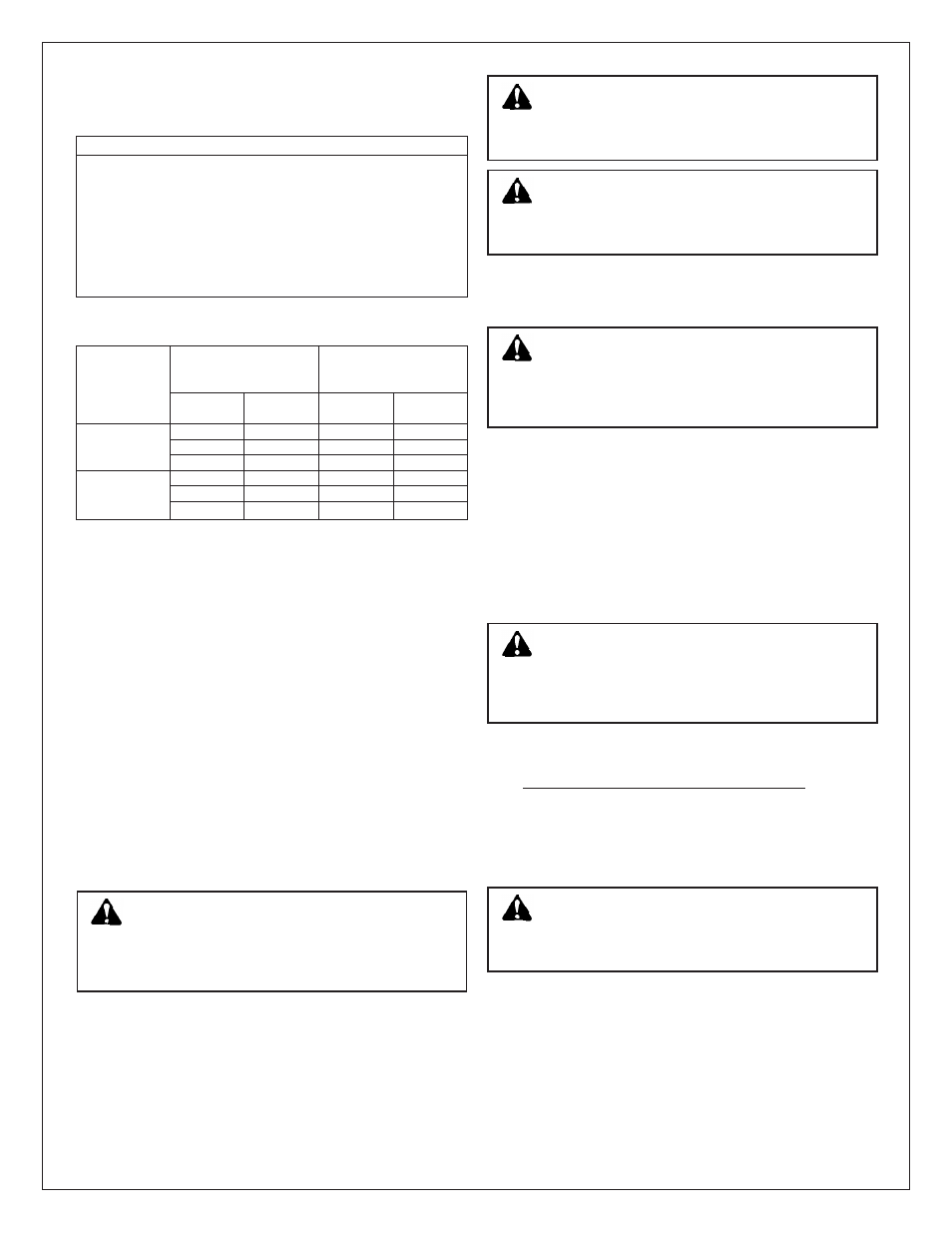

OPERATIONAL LIMITS

(These products are designed for use with water or glycol

products only in hydronic systems.)

Accessory

Temp ˚F (˚C)

Pressure psi (kPa)

Shutoff valves (NPT)

250 (121)

300 (2068.5)

Shutoff valves (sweat)

Based on solder type ASTM Std. B16.18

Strainers (NPT)

250 (121)

300 (2068.5)

Strainers (sweat)

Based on solder type ASTM Std. B16.18

Hose

1

/

2

"

210 (99)

375 (2585.6)

Hose

3

/

4

"

210 (99)

300 (2068.5)

Hose 1"

210 (99)

290 (2000)

Hose 1

1

/

4

"

210 (99)

217 (1496)

Hose 1

1

/

2

210 (99)

145 (1000)

WORKING PRESSURE & TEMPERATURE LIMITS

(SOLDER TYPE LIMITS FOR ANSI STD. B16.18)

INSTALLATION INSTRUCTIONS

(STRAINERS AND SHUTOFF VALVES)

1. The Shutoff Valves are bi-directional and can be installed in

piping with flow in either direction.

2. The Y-Strainers must be installed with the flow in the direc-

tion of the flow arrow on the strainer body.

3. When installing either the shutoff valves or the strainers,

space around the units must be provided to move the valve

handle to the shutoff position and to remove the strainer

from the strainer body for cleaning.

4. The Y-Strainer must be installed with the strainer chamber

down to prevent air binding and also to allow accumulated

dirt to be blown down from the strainer. It is a good idea to

install a blowdown line and a shutoff valve to the strainer Y

connection so that accumulated dirt can be removed.

5. When soldering the sweat type shutoff valves or sweat type

strainer into the piping, make sure that valves are not

heated above 500˚F (260˚C). Wet rags should be used to

keep the valve body temperatures down to prevent damage

from excessive heat.

• Use a torch with a sharp pointed flame.

• Clean tube ends and shutoff valve or strainer connections

thoroughly.

• Use 95-5 (Tin-Antimony), 50-50 or 60-40 (Tin-Lead)

solders only, and a good grade of flux.

Check soldered connections for leaks. Resolder if necessary.

6. For NPT type joints apply pipe compound conservatively to

male connecting fittings only.

Check connections for leaks.

INSTALLATION INSTRUCTIONS

(HOSE ASSEMBLIES)

1. The hose assemblies are supplied with a male NPT pipe

connector on one end and a union coupling and male NPT

adapter on the other end. For

1

/

2

" through 1" sizes the male

NPT adapter is furnished with a metal to metal joint which

connects to the union coupling. 1

1

/

4

" and 1

1

/

2

" sizes are sup-

plied with a fiber gasket instead of a metal to metal joint with

a union coupling.

2. When installing hoses, slack must be provided and the bend

radius must equal or exceed those shown below.

Hose Size

Minimum Bend Radius

1

/

2

"

3" (76.2 mm)

3

/

4

"

5" (127 mm)

1"

6" (152.4 mm)

1

1

/

4

"

7

1

/

2

" (190.5 mm)

1

1

/

2

"

9" (228.6 mm)

3. Pipe joint compound must be sparingly applied to the male

NPT threads only. Do not apply joint compound to the

adapter threads that mate with the union connector.

4. Hose must not be twisted while it is being installed. The

union joint must be tightened last and it must be held with

two wrenches to prevent the hose from twisting.

2

CAUTION:

Excessive use of solder or flux may

result in damage to the shutoff valve seat and ball.

Do not use excessive solder or flux. Failure to follow these

instructions can result in moderate personal injury and/or

property damage.

CAUTION:

The use of Teflon impregnated pipe

compound and Teflon tape on pipe threads provides

lubricity. Care should be taken to prevent overtightening

which may damage the shutoff valves or strainers. Failure

to follow these instructions can result in moderate per-

sonal injury and/or property damage.

WARNING:

Damage to the shutoff valves or strainers

or failure of solder sealing joints may occur if the

solder joint operational limits are exceeded. This can re-

sult in water leakage. Failure to follow these instructions

could result in serious personal injury and/or property

damage.

Maximum

Maximum

Limitations

Limitations

Type of

1

/

2

" - 1"

1

1

/

4

" - 1

1

/

2

"

Solder

Pressure

Temp

Pressure

Temp

psi (kPa)

˚F (˚C)

psi (kPa)

˚F (˚C)

95-5

300 (2069)

200 (93)

300 (2069)

175 (79)

Tin-

250 (1724)

225 (107)

250 (1724)

200 (93)

Antimony

200 (1379)

250 (121)

175 (1207)

250 (121)

50-50 and

200 (1379)

100 (38)

175 (1207)

100 (38)

60-40

150 (1034)

150 (66)

125 (862)

150 (66)

Tin-Lead

85 (586)

250 (121)

75 (517)

250 (121)

CAUTION:

Heat associated with the use of silver

solder may damage the shutoff valves or the strainers

voiding the warranty. Do not use silver solder. Failure to

follow these instructions can result in moderate personal

injury and/or property damage.

WARNING:

These hoses are designed for use with

water and glycol based fluids in hydronic systems.

Do not use hydrocarbon based fluids or other fluids in

these hoses. Failure to follow these instructions could

result in serious personal injury, death and/or property

damage.

WARNING:

Hose assemblies may rupture if slack is

not provided or the bend radius is less than re-

quired. Make sure that these requirements are provided.

Failure to follow these instructions could result in serious

personal injury, death and/or property damage.