Bell & Gossett HT 50B SM B&G Series U Heat Exchangers Removable Bundle Design User Manual

Page 5

5

WARNING: It is extremely important to follow a

proper tightening sequence. If it is not followed, the

flanges can become cocked and a leak will result. When

tightening flanges with spiral wound gaskets, if cocking

occurs, the result can be deformation and non-repairable

damage to the gaskets in addition to a resultant leak.

Any gasket leak can result in potential injury to adjacent

personnel.

TIGHTENING TORQUES

Tightening tip: It is essential that the installer follows the

gasket manufacturer’s installation guidelines when

installing gaskets. Metallic gaskets, such as the spiral

wound gaskets, usually have special installation instruc-

tions. One of these instructions includes a special proce-

dure for tightening bolts/studs when installing new gas-

kets. The procedure recommends that the bolts/studs be

torqued in four stages.

a. Following the staggered tightening pattern, the bolts/

studs should be torqued to

1

/

3

of the recommended

tightening torque.

b. Same as a, the bolts/studs should be torqued to

2

/

3

of

the recommended tightening torque.

c. Same as a, the bolts/studs should be torqued to the

recommmended torque valve shown in the above chart.

d. Following the staggered tightening pattern the bolts/

studs torques should be checked for equilibrium since

the tightening of one bolt/stud can relieve the stress on

adjacent bolts/studs.

If after following the gasket manufacturer’s recommended

tightening procedure a leak still occurs, the bolts/studs

should be tightened in the torque increments shown until

the leak stops. The staggered tightening pattern is still

followed.

NOTE: When using spiral wound gaskets, both the head

and the shell/tank gaskets must be spiral wound. You can-

not mix one spiral wound and one compressed fiber gas-

ket on a heat exchanger.

13. Refer to “OPERATION” steps 5 and 6 regarding bolt re-

tightening after start-up.

14. Where frequent disassembly of the heat exchanger is

encountered, the use of new bolting in conformance with

dimension and ASTM specifications of the original design

is recommended.

1

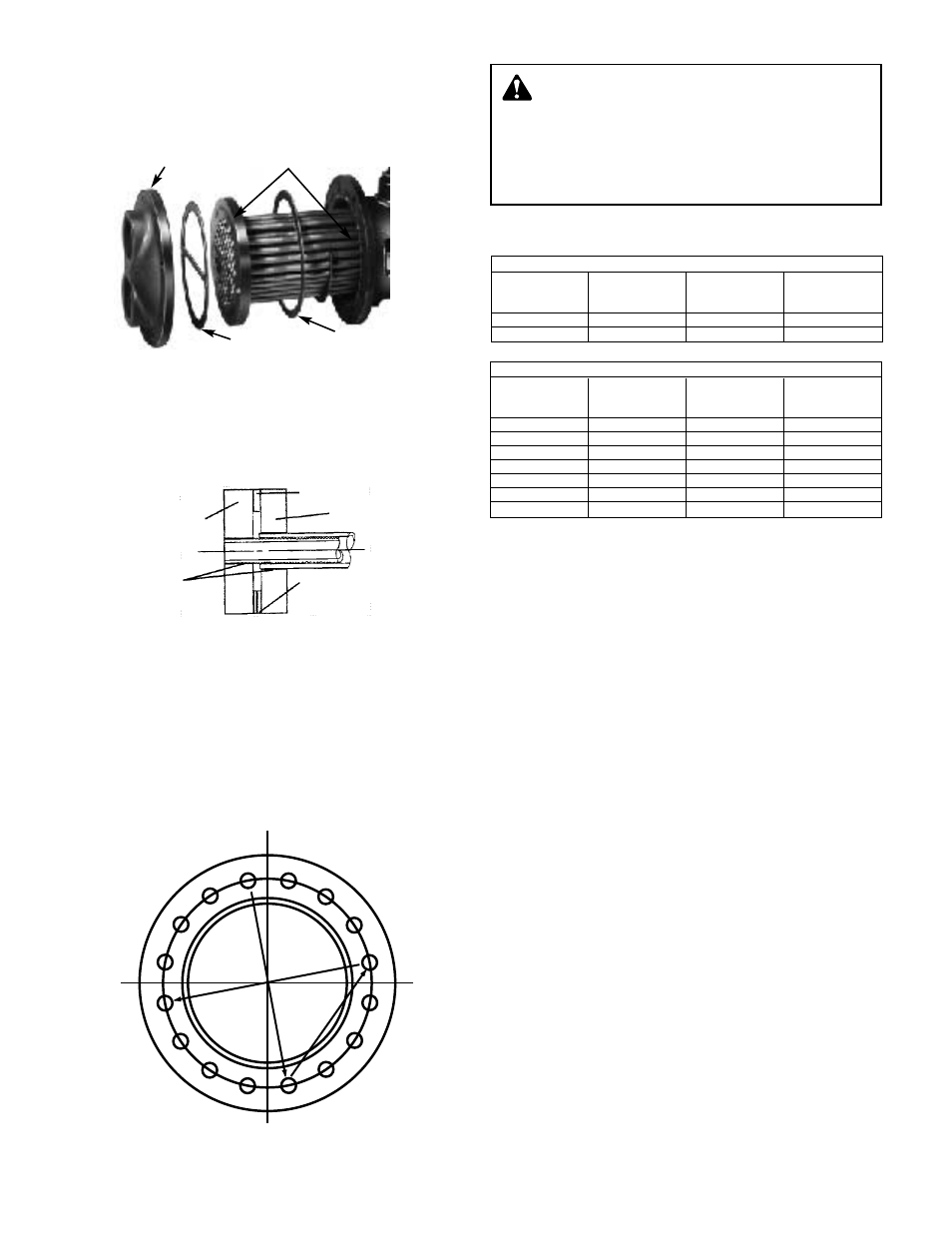

9. Before reinserting the tube bundle into the shell or collar

of a tank, place the ring/tank gasket over the end of the

tube bundle and bring forward to the backside of the

tubesheet.

10. The tube bundle can be replaced using the tools and

reverse procedure given for bundle removal.

11. When installing a Diamondback™ double-wall tube bun-

dle, make sure the leak path drain hole in the spacer ring

between the two tubesheets is in the lowest position of

the tubesheet circle.

12. When replacing the heads, use a torque wrench to tighten

the bolts/studs and nuts. Use the following chart as

a guide. All torque values apply to well lubricated nut

bearing surfaces.

All bolted joints should be tightened uniformally and in a

diametrically staggered pattern as illustrated below:

1

2

3

4

6

9

14

7

15

12

5

10

13

8

11

16

START

TUBESIDE

TUBESHEET

SPACER RING

SHELLSIDE

TUBESHEET

CL TUBE

LEAK PATH

MECHANICALLY

ROLLED

TUBE

JOINT

DOUBLE-WALL TUBE JOINT

COMPRESSED FIBER GASKETS

Recommended

Bolt

Torque

Torque

Max.

Dia.

ft-lbs

Increment

Torque

1

/

2

"

40

5

60

5

/

8

"

80

5

120

SPIRAL WOUND GASKETS

Recommended

Bolt/Stud

Torque

Torque

Max.

Dia.

ft-lbs

Increment

Torque

1

/

2

"

1

40

1

5

11

60

5

/

8

"

1

80

1

5

1

120

3

/

4

"

120

1

5

1

200

7

/

8

"

200

10

1

320

1"

300

10

1

490

1

1

/

8

"

450

10

1

710

1

1

/

4

"

600

10

1000

HEAD GASKET

TANK GASKET

FRONT

HEAD

TUBE BUNDLE

(PARTIALLY REMOVED)