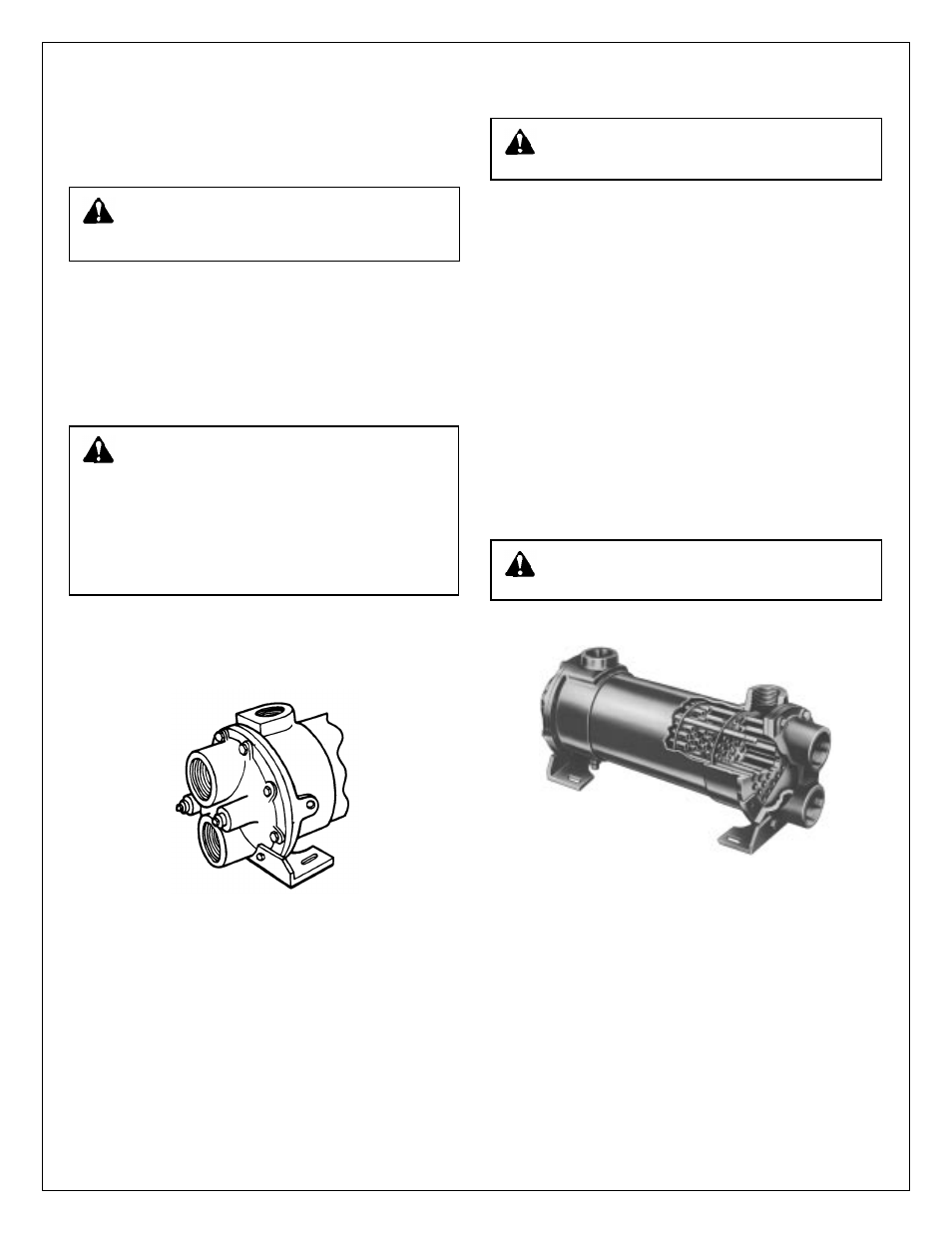

Bell & Gossett HT 202A SM Models CHXS Fixed Tube Sheet Heat Exchangers User Manual

Page 3

5. Do not blow out heat exchangers with air when operating

fluids are of a flammable or otherwise hazardous nature.

WARNING: Proper precautions must be taken (special

clothing, equipment, etc.) to protect personnel from

injury due to escaping fluids.

6. Provide convenient means for frequently cleaning heat

exchangers as suggested below:

a. Circulating hot wash oil or light distillate through tubes or

shell at good velocity will effectually remove sludge or

other similar soft deposits.

b. Soft salt deposits may be washed out by circulating hot

fresh water.

c. Some cleaning compounds on the market, such as

“Oakite” may be used to advantage for removing sludge or

coke, provided hot wash oil or water, as described above,

does not give satisfactory results.

d. If none of the above described methods are effective for

the removal of hard scale or coke a mechanical means

may be used. The interior of the tubes may be rodded.

e. The exterior or shell side of the tubes of a fixed sheet heat

exchanger can only be cleaned chemically by using a

chemical dissolved in water solution. We suggest that the

user contact the manufacturer of the cleaning chemical for

instructions.

WARNING: Care must be exercised when handling

certain fluids. Follow manufacturers instructions. Use

eye and skin protection. Wear a respirator when required.

3. In shutting down, flow of hot medium should be shut off first.

If it is necessary to stop circulation of cooling medium the cir-

culation of hot medium should also be stopped by by-passing

or otherwise.

4. Do not operate equipment under conditions in excess of those

specified on nameplate.

WARNING: Failure to operate the heat exchanger

within the design pressure and temperature on the

nameplate may result in damage to the heat exchanger and

potential injury to adjacent personnel.

5. Drain all fluids when shutting down to eliminate possibility of

freezing and corrosion. To guard against water hammer, con-

densate should be drained from steam heaters and similar

apparatus both when starting up and when shutting down.

6. In all installations there should be no pulsation of fluids since

this causes vibration and strain with resulting leaks.

7. All gasketed joints should be checked after starting for leaks

and tightened if necessary.

WARNING: The CHX and CHXS exchangers are suit

able for use as heaters using steam as the heating

medium. These exchangers are, however, fixed tubesheet

units and, therefore, not designed to absorb thermal shock

inherent in the intermittant service of on and off heating

with frequent short intervals of demand. Their recom-

mended use is where service is continuous or steady, with

relatively long periods between shutdown and start-up.

Heat exchanger failure due to thermal shock may result in

potential personal injury.

MAINTENANCE

1. Do not open heads until all pressure is off equipment and the

unit is drained.

2. Remove the bonnets. Inspect all tubes carefully for possible

erosion, corrosion, or foreign material.

3. Inspect all anodes to be sure they are neither excessively cor-

roded nor insulated with scale. Scrape to a bright surface.

4. Inspect filters in the system to prevent foreign matter from

entering the exchanger.

3

7. When replacing heads, use a torque wrench.* Tighten

1

/

4

"

diameter bolts (2” diameter units) to 6 ft-lbs.,

5

/

16

" diameter

bolts (3" & 4" diameter units) to 16 ft-lbs., and

3

/

8

" diameter

bolts (5", 6", & 8" diameter units) to 24 ft-lbs. If the gasket joint

still leaks, tighten in 2 ft-lb. increments until leak stops.

*The above torque values apply to well lubricated nut bearing

*

surfaces.