Planning the installation – Bell & Gossett HS 601G Pilot Operated Pressure and/or Temperature Steam Regulators Series 2000 User Manual

Page 2

2

PLANNING THE INSTALLATION

Planning for the Pilot Installation

1. The regulator main valve must be located in an

accessible straight run of horizontal piping.

NOTE: Main valve must be installed with diaphragm

located on bottom, as shown in Main Valve Installation

illustration, page 3.

2. Allow clearance on top of the main valve to remove

the cover plate to inspect and service the valve.

3. Allow clearance under the main valve diaphragm

cover to replace diaphragms and drop out the stem

for service.

4. Piping should be sized per good engineering practice.

HVAC applications generally use 6,000 FPM velocity.

Industrial applications generally use 8,000 to 10,000

FPM.

5. Blow out all piping with steam or compressed air before

installing the main valve to remove mill scale and dirt.

6. Use long radius elbows in the low pressure piping.

Avoid the use of bull-headed tees.

7. Provide a bypass line with a globe valve to allow

inspection without interrupting service.

8. Install pressure gauges on inlet and outlet sides of

regulator to indicate system performance.

9. Install drip traps to prevent:

• Accumulation of condensate that can cause water

hammer and destroy the main valve and pilot

diaphragms.

• Slow response times that cause temperature or

pressure fluctuations.

10. Install "Y" Strainers in steam lines with the dirt pocket

turned to the side to prevent collection of condensate

that can be carried into the regulator and cause water

hammer.

11. Install pressure relief valves in accordance with local

and national codes. The relief valve must be capable

of passing the full capacity of the regulator with its

largest seat trim.

Select the relief valve opening set point pressure

based on the downstream pressure from the regulator.

The actual relief valve set point pressure depends on

the relationship of the flow (load) to the main valve

rated capacity.

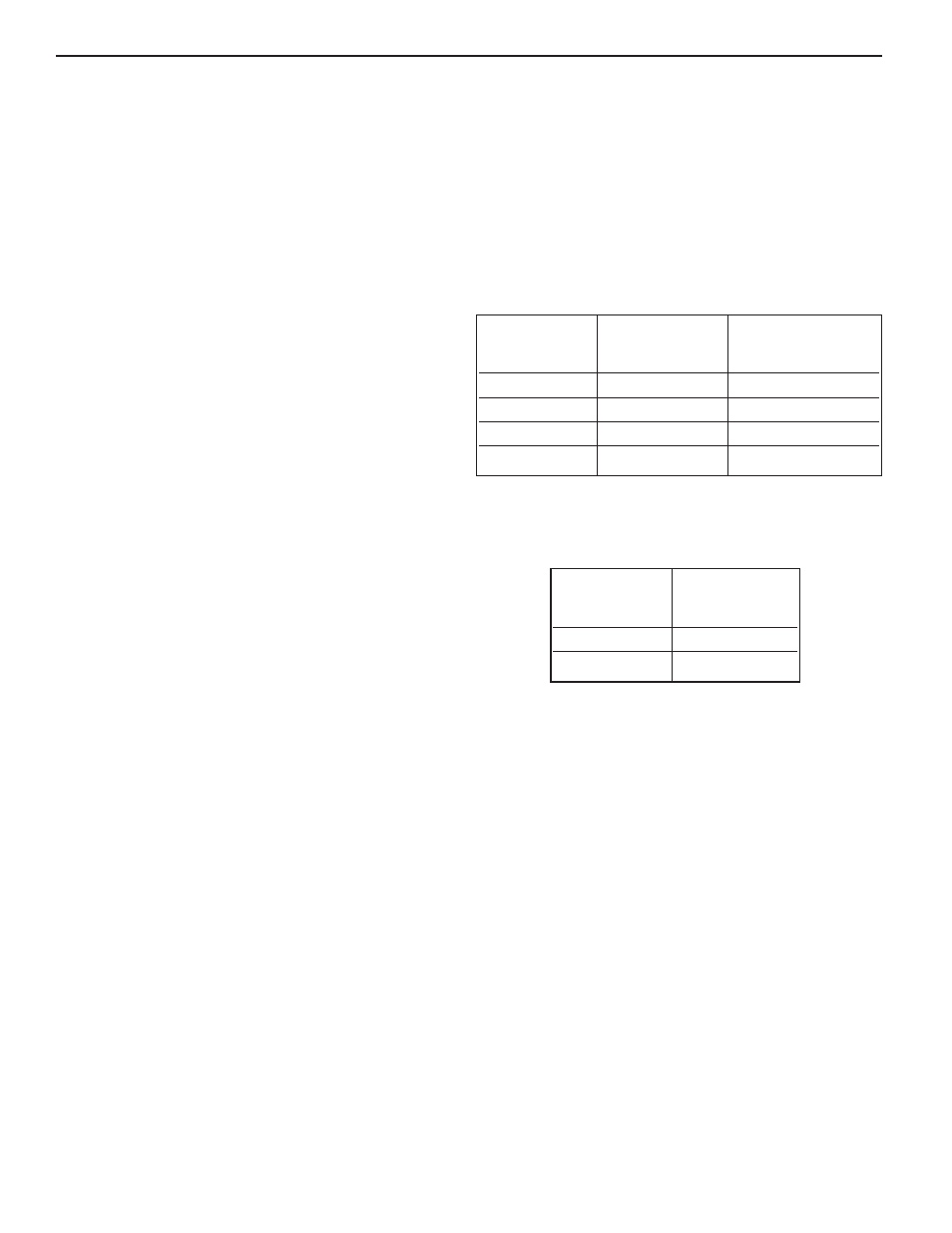

For systems with spring or air pilots:

Determine the relief pressure set point pressure for

systems as follows:

For systems with temperature pilots only:

The steam system relief valve opening set point

pressure is based on the supply steam inlet pressure

to the regulator and must be set as follows:

12. Locate temperature regulators close to the temperature

sensing location. The temperature pilot capillary tube

must allow the sensing bulb to be fully inserted into

the system fluid.

Downstream

Flow

Relief valve

System

(Load)

opening set

Pressure (DSP)

Condition

point pressure

< 35 psig

< 50% of capacity

DSP + 5 psig

< 35 psig

≥ 51% of capacity (1.1 x DSP) + 5 psig

≥36 psig

< 50% of capacity

DSP + 10 psig

≥36 psig

≥ 51% of capacity (1.1 x DSP) + 10 psig

1. The pilot valves can be installed on either side of the

main valve. The main valve is shipped with the U-tubing

and the bleed orifice installed for left-hand side

mounting of the pilot valves. (U-tubing is mounted on

the right-hand side and the bleed orifice is installed

on the left-hand side.)

If right-hand side mounting of the pilot(s) is desired,

the U-tubing and the bleed orifice must be relocated

to the opposite sides of the main valve.

Note: Right-hand side and left-hand side positioning

is determined when the main valve inlet directly faces

the observer.

2. Determine which pilot(s) are to be used for the instal-

lation. Multiple pilots can be used in combination on

one main valve. Mount the pilot(s) as follows:

• SLD Solenoid Pilot

Always mount closest to the main valve.

• SPS Spring or AP Air Pressure Pilots

When used in combination with other pilots,

always mount spring or air pilots furthest from

the main valve.

• STPA Temperature Pilot

When used with pressure pilot mount closest to

main valve.

When used with pressure and solenoid pilots –

mount between pressure and solenoid pilots.

• 315 PNT or 240PNT Pneumatic Temperature

Pilots

Mounted remotely from main valve.

• GT610-IP Electronic Pilot (used with customer

supplied temperature sensor and controller)

Mounted remotely from main valve.

3. Hardware kits containing steel pipe nipples and

copper tube lines are required to mount the pilots.

Refer to "Mounting Hardware for Pilot Installation"

Page 4.

Planning for the Main Valve Installation

Supply Steam

Relief valve

Inlet Pressure

opening set

(SSIP)

point pressure

< 35 psig

SSIP + 5 psig

≥36 psig

SSIP + 10 psig