Bell & Gossett HS 601G Pilot Operated Pressure and/or Temperature Steam Regulators Series 2000 User Manual

Page 15

6. Inspect the valve seat and plug for deep scratches or

deposits. Clean or replace if necessary.

7. Place a light film of valve lapping compound on the

plug seating surface. Using 400 grit or finer lapping

compound is recommended. (Generally available from

automotive supply stores.)

8. Slide the plug on the valve stem. Do not install the

lock washer or nut for lapping.

9. Slowly reduce the air loading on the main valve

diaphragm until the plug touches on the valve seat.

• Approximately 5 psig on Series 2100, 2200 and

2300 main valves.

• 1 to 2 psig on Series 2150 and 2250 main valves.

10. Use the following procedure:

• Rotate the plug back and forth about 90 degrees.

• Use light hand pressure.

• Lap for about 30 seconds.

• Rotate the plug 120 degrees and repeat.

• Rotate the plug another 120 degrees and repeat.

• Remove the plug and use a clean cloth to wipe

the plug.

• The plug and seat should show a dull area where

the lapping occurred.

• Inspect to make sure the plug and seat made

contact completely around the diameter.

• If the contact area is not completely around the

diameter repeat the process.

11. Increase the air loading to approximately 60-80 psig.

Make sure the plug and seat are clean. Reinstall the

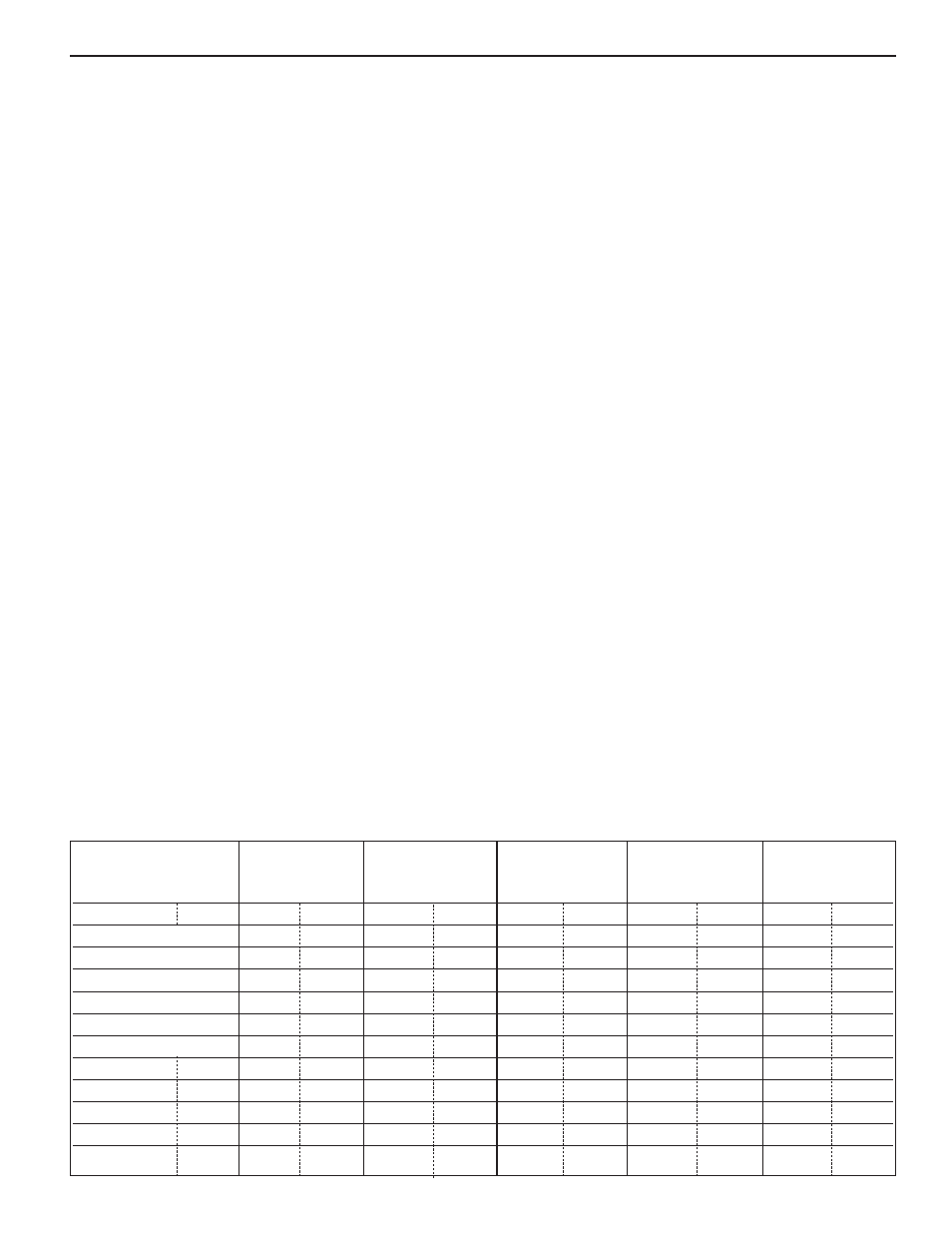

plug, lock washer and nut. See "Tightening Torque for

Series 2000 Main Valve" chart, below, for torque

specification.

12. Reduce the air loading pressure on the main valve

diaphragm area to 0 psig (0 bar). Observe the stem

movement for smooth stroking.

13. Replace top cover and stem guide (if used) using a

new gasket. Tighten the cover bolts to torque shown

in the "Tightening Torque for Series 2000 Main Valve"

chart, below.

14. Reconnect the steam tubing line to the main valve

diaphragm. Slowly apply steam pressure and inspect

for external leaks. Tighten as necessary or replace

components to stop any leaks.

15. Return the main valve to service.

Main Valve Diaphragm Replacement

A leak in the diaphragm will not allow full steam pressure

to build up under the diaphragm and the valve will not

fully open.

1. Isolate the main valve from the steam line. Make sure

the internal pressure is 0 psig and allow the valve to

cool to prevent injury.

2. Remove the copper tubing line that connects to the

diaphragm cover.

3. Loosen all nuts on diaphragm cover bolts.

4. Remove the bolts completely from

only one side of

the valve.

5. Use a pair of needlenose pliers to remove the

diaphragms from the side of the valve without the bolts.

6. Insert new diaphragms and replace the bolts. Using a

star pattern, tighten the diaphragm cover bolts, a

minimum of three times, to the torque value shown in

the "Tightening Torque for Series 2000 Main Valve"

chart below.

NOTE: On 2150 and 2250 main valves, connect a

source of regulated air pressure to the 1/4" NPT port

located on the opposite side of the valve from the pilot

inlet line. Load the inlet side of the valve with 30-50

psig (2.1 to 3.5 bar) pressure before tightening

diaphragm cover bolts.

7. Reinstall the copper tubing line and return valve to

service. Inspect for leaks.

Main

Stem

Nut

Top

Diaphragm

Valve

to

to

Cover

Cover

Size

Button

Stem

Seat

Bolts *

Bolts *

in.

mm

lbf-ft

N-m

lbf-ft

N-m

lbf-ft

N-m

lbf-ft

N-m

lbf-ft

N-m

1/2 NPT

6

8

11

15

10

14

31

42

31

42

3/4 NPT

6

8

11

15

10

14

31

42

31

42

1 NPT

6

8

11

15

10

14

31

42

31

42

1-1/4 NPT

20

27

20

27

20

27

75

102

31

42

1-1/2 NPT

20

27

20

27

20

27

75

102

31

42

2 NPT

20

27

20

27

20

27

75

102

75

102

2

50

20

27

20

27

20

27

75

102

75

102

2-1/2

65

31

42

43

58

30

41

150

204

75

102

3

80

31

42

43

58

30

41

150

204

75

102

4

100

31

42

43

58

40

54

150

204

150

204

6

150

31

42

43

58

50

68

150

204

250

340

Tightening Torque for Series 2000 Main Valve

* Tighten cover bolts a minimum of three times using an even star pattern.

15