Changing a thermostatic actuator on two-way valves, Caution – Bell & Gossett HS 504F Series 1141 Temperature Regulators User Manual

Page 6

6

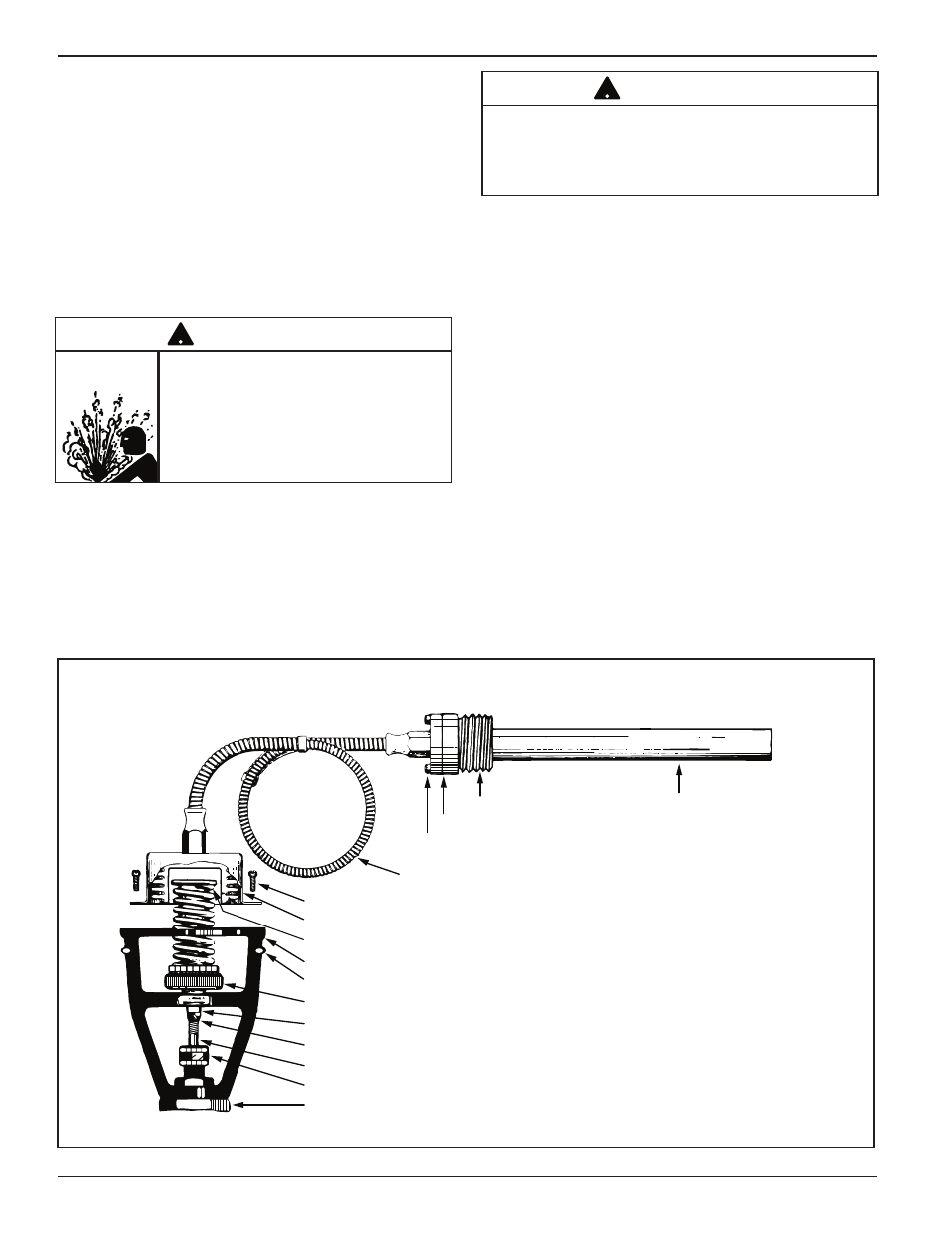

CHANGING A THERMOSTATIC

ACTUATOR ON TWO-WAY VALVES

The Thermostatic Actuator used on the Series 1140 reg-

ulators is shown in Figure No. 11. All actuator parts

shown form one inseparable unit, except for the bulb

bushing with its gasket and fastening screws.

The Thermostatic Actuator will only control within the

temperature range stamped on the name plate, which is

fastened to the bellows housing.

If it is necessary to install a new actuator, to obtain a

higher or lower range, the following procedure should be

applied. Refer to Figure No. 11.

1. On units without a separable well, drain tank or pipe

line to a point below location of the thermostatic bulb.

2. Loosen the four (4) bulb bushing screws and slowly

break the bulb connection to make sure hot water

does not drain out, then remove four (4) screws and

take the bulb out of the bushing or well.

3. Turn temperature adjustment wheel to lowest position

(clockwise).

4. Cool bulb and bellows at least 20˚F (-6˚C) below low-

est temperature of range indicated on name plate.

5. Remove the bellows housing nuts and screws and lift

unit off bracket (keep bulb cool). Push down by hand

on upper valve stem plate until valve is shut. With a

pencil make a reference mark on the lower valve

stem, where stem enters stuffing box nut. This will

assist in checking total valve movement on opening

and also the thrust of the new thermostatic actuator.

6. Cool the new thermostatic actuator bulb which is to be

installed, at least 20°F (-6˚C) lower than the lowest

temperature marked on the name plate.

Actuators for valves in sizes 2-1/2" to 4" and with

ranges lower than 120° to 160°F (49 to 71°C) are

shipped with a clip, so that the bellows cannot expand

beyond limits in transit. Before removing this clip,

make sure you can compress bellows by hand. Only

then remove clip and attach housing to bracket, by

fastening the six (6) bellows housing screws. This

must be done quickly.

7. Recheck valve stem travel as outlined in paragraph

“Checking Valve Stem Travel” on page 5.

REGULATOR BODY

STUFFING BOX NUT

LOWER VALVE STEM

UPPER VALVE STEM

TEMPERATURE ADJUSTMENT WHEEL

BELLOWS HOUSING NUT

BRACKET

UPPER VALVE STEM PLATE

BELLOWS HOUSING

BELLOWS HOUSING SCREW

ARMORED CAPILLARY TUBING

BULB BUSHING SCREWS

GASKET

BULB BUSHING

THERMOSTATIC BULB

STEM ADJUSTMENT LOCK NUT

Figure No. 11

CAUTION

ALL SUPPLY VALVES MUST BE

TURNED OFF, SYSTEM PRESSURE

MUST BE REDUCED TO 0 psi (0 bar),

AND SYSTEM TEMPERATURE MUST BE

REDUCED BELOW 100˚F (38˚C) BEFORE

REMOVING THE BULB. FAILURE TO

FOLLOW THIS CAUTION MAY RESULT

IN SERIOUS BURNS.

!

CAUTION

REGULATORS OPERATING LOWER THAN 120˚ - 160˚

(49˚ - 71˚C) OR IN ROOMS ABOVE 100˚F (38˚C), THE

BELLOWS MUST BE COOLED UNTIL IT CAN BE

COMPRESSED BY HAND. FAILURE TO FOLLOW

THIS CAUTION COULD DESTROY THE ACTUATOR.

!