Operating principle, Valve installation – Bell & Gossett HS 504F Series 1141 Temperature Regulators User Manual

Page 2

OPERATING PRINCIPLE

This Series 1140 regulator automatically controls the

flow of steam, water or other medium passing through

its valve by responding to temperature changes at the

bulb. The bulb contains a liquid which vaporizes when

heated. Vapor pressure generated in bulb is transmitted

through the capillary tubing to the flexible bellows which

moves the valve disc or plunger controlling the flow of

the medium through the valve. Movement of the bellows

is opposed by a spring, providing a means of adjust-

ment. The regulator only controls within the temperature

range stamped on the name plate and can be adjusted

to control at any point within its range.

VALVE INSTALLATION

Before installing confirm proper sizing.

Oversized valves will not provide good

temperature control.

The location and installation of the regulating valve is

very important. A pipe line strainer must be installed

ahead of all double seated and balanced single seated

regulators. Single seated valves have built-in removable

strainers. However, it is still good practice to install a

strainer before all regulators and to blow all lines of

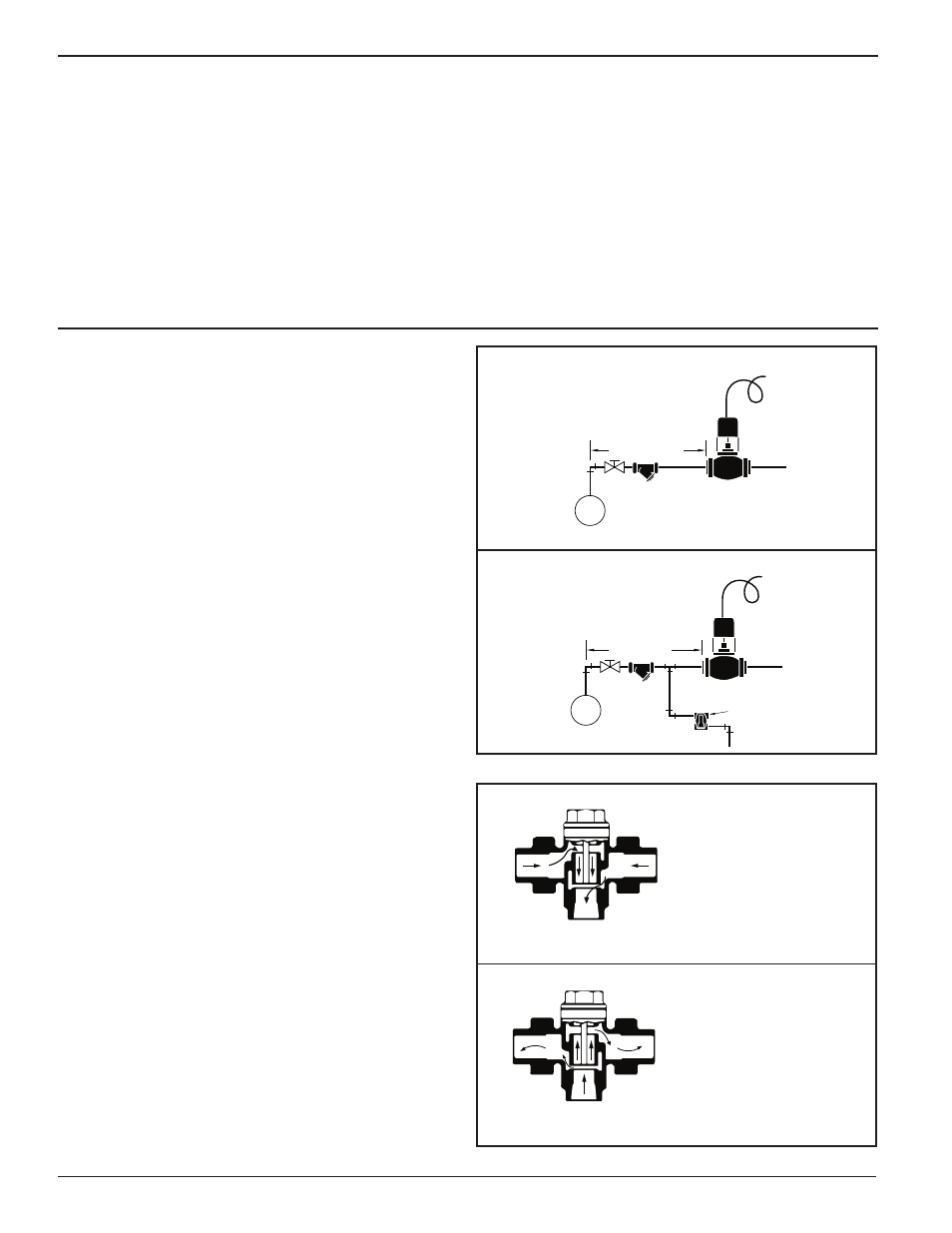

foreign matter on installation. See Figure No. 1.

The regulating valve should be installed as close as

possible to the unit being controlled. The regulator must

be installed in a vertical position, the bracket assembly

above the valve body. Install valve so that arrow cast on

valve body points in direction of steam or liquid flow.

When controlling steam, the heater or coil should be

properly vented and drained. A plain bucket trap should

not be used without some provision to eliminate air from

the coil. A drip trap should be installed ahead of all

steam regulators. See Figure No. 2.

When controlling flow of water used for cooling, the

valve can be installed on the supply end and may also

be installed on the discharge end of the unit. The

position depends largely on the particular case, as some

units, such as cylinder liners, cannot stand the full line

pressure.

When mixing hot and cold water, check valves should

be used on the supplies to the three-way valve, unless

the three way valve is used directly at heat exchanger

(see Figure No. 3) then check valve need only be on the

cold water side. To avoid temperature fluctuation of

tempered water line, the thermostatic bulb should be

located as close to three-way valve as possible.

These size valves are furnished with standard capillary

tubing, 10' (3m) length: 1/2" to 2" NPT and 2-1/2" to 4"

(65 to 100 mm).

Three-way valves are sometimes used as diverting

valves. See Figure No. 4.

C

B

A

Outlet

HOT

IN

COLD

IN

2

Valves used to control heating cycles are direct acting,

i.e., they shut off on increase of temperature.

Valves used to control cooling cycles are reverse acting,

i.e., they open on increase of temperature.

Three-way valves are used to mix hot and cold water,

or as diverting valves (see Figure 3 and 4 below).

It is necessary that the sensing bulb be completely

immersed in the fluid being controlled.

C

B

A

Inlet

Figure No. 1 - Trapping ahead of steam regulators

Figure No. 2 - Trapping ahead of steam regulators

Series 1140,

3-way valve

mixing service

When temperature

increases piston moves

down closing port ‘B’

opening port ‘C’.

Series 1140,

3-way valve

diverting service

When temperature

increases piston moves

down closing port ‘B’

opening port ‘C’.

Figure No. 3

Figure No. 4

OVER 10' (3 m)

PITCH TOWARD

STEAM REGULATOR

MAIN 1/2" PER FOOT

(15 MM PER 0.3 m)

STEAM

MAIN

TRAP

10' (3 m) OR LESS

PITCH TOWARD STEAM REGULATOR

MAIN 1/2" PER FOOT

(15 mm per 0.3 m)

STEAM

MAIN