Bell & Gossett DN0162F HS Vented Boiler Feed Units Series HBF and VBF User Manual

Page 8

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. DN0162F November 2012

(4) The carbon ring of the rotating seal part should not be

loose in the seal head. If it is, apply a small amount of

grease to the rubber bellows underneath the carbon

ring to hold the ring in place. Using clean, lint free

cloth, wipe mating surfaces perfectly clean. Soap shaft

and push seal onto shaft so that carbon will contact

ceramic seal. If spacer is required, use grease to cause

spacer to adhere to bottom of seal after seal has been

put on shaft. Be sure spacer is on larger diameter of

shaft so that it will not catch between shoulder and

impeller.

13. Replace impeller on shaft. Replace stainless steel washer

and secure impeller with capscrew or cap nut.

14. Place new gasket on pump volute and reassemble motor

and pump subassembly on pump volute.

15. Reconnect pump bleed line and motor wiring.

16. Close drain and slowly open inlet valves. See warning.

17. Jog to check motor rotation. See caution.

18. Observe operation thru several cycles.

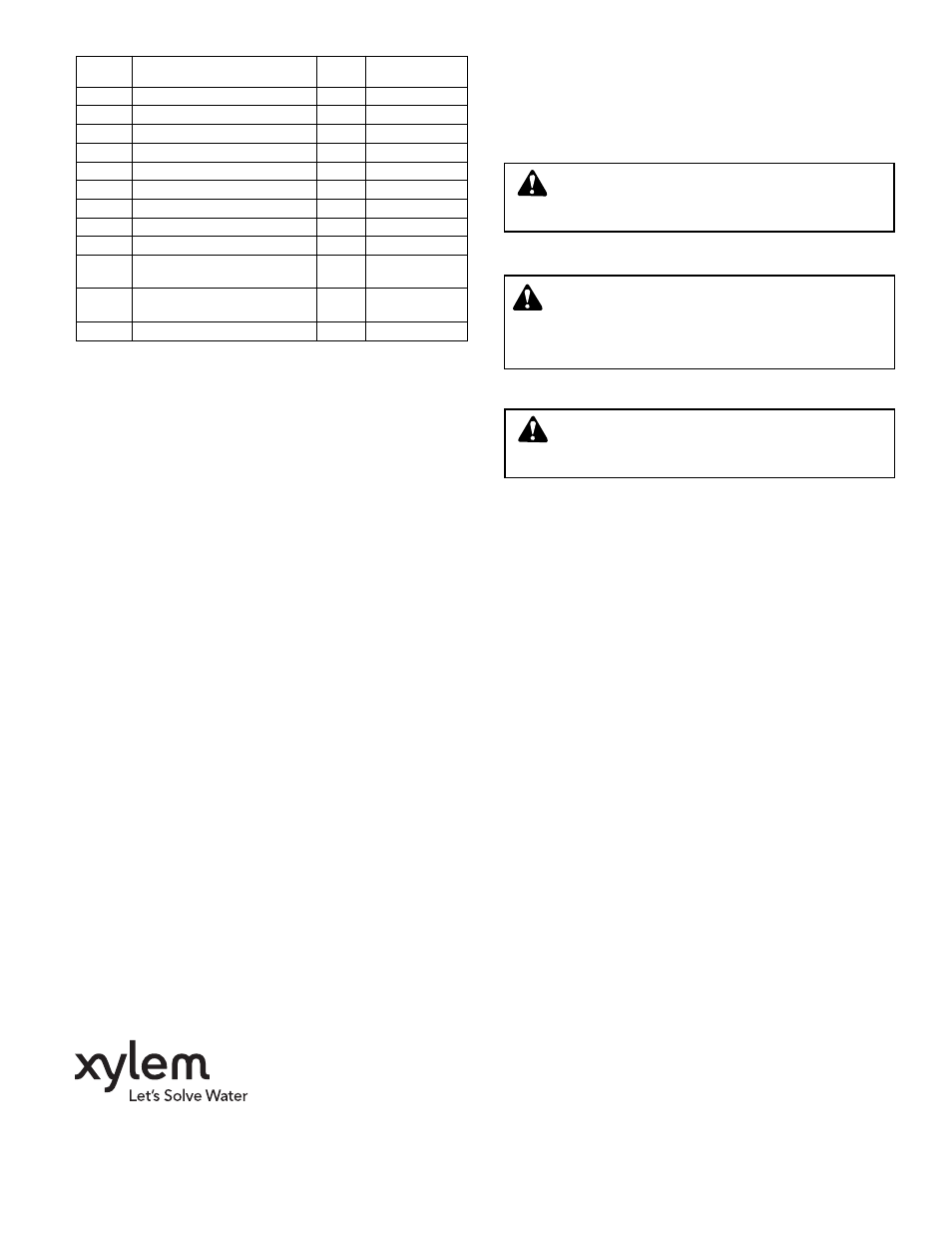

Item

No.

Part

Number

Description

Req’d.

No.

1

Motor — Order by Description

1

Consult Factory

2

Impeller

1

Consult Factory

3

Pump Head

1

DP0208

4

Case with Wear Ring

1

DP1603

5

Wearing Ring

1

DP0482

8

Impeller Capscrew

1

DJ0213

9

Impeller Washer

1

DJ0267

10

Capscrews

8

DJ0066

18

Water Slinger

1

DP0848

Seal Kit Including Mech

6,7

Seal, Head Gasket

1

180014

Complete Pump and

Motor Assembly

1

Consult Factory

Case to Rec. Gasket

1

DG0060

Order Replacement Parts by Description and Part No.

Specify Serial No. shown on nameplate.

CAUTION / DO NOT RUN DRY. SEAL DAMAGE

MAY OCCUR: Inspect pump seal regularly for

leaks. Replace as required. Failure to follow these

instructions could result in injury or property damage.

CAUTION / DO NOT REVERSE: Reverse operation

can cause extensive damage to pumps. Jog the

motor to test for direction of rotation. Failure to follow

these instructions could result in injury or property damage.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.