Bell & Gossett DN0162F HS Vented Boiler Feed Units Series HBF and VBF User Manual

Page 7

7

17. Close drain and slowly open inlet valves. See warning.

18. Jog to check motor rotation. See caution.

19. Observe operation thru several cycles.

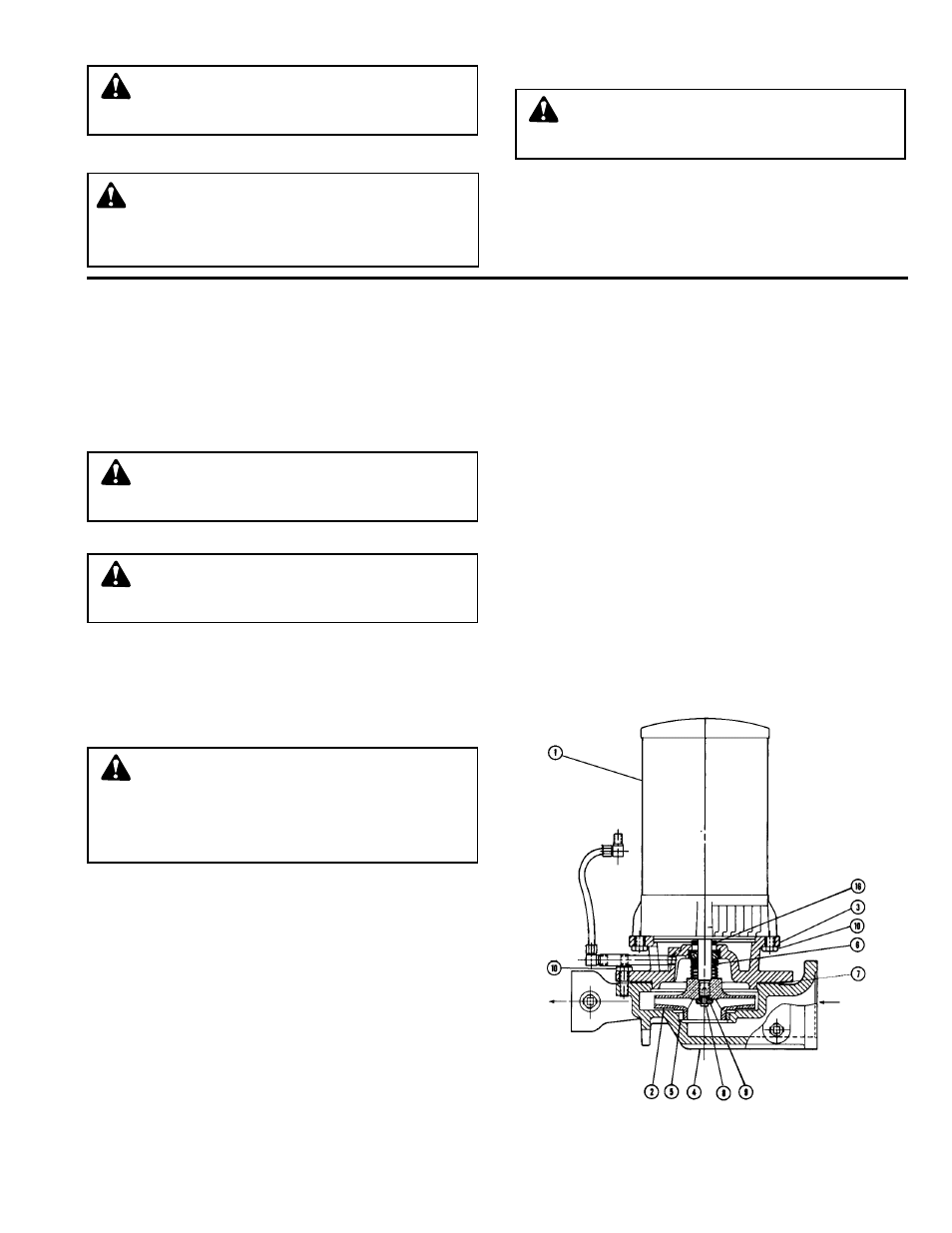

Close coupled centrifugal pumps are designed for years of

trouble free service. Units have mechanical shaft seals.

1. Close inlet line gate valve and operate pump momentarily

to remove as much liquid as possible from pump. Close

discharge line gate valve.

2. Shut-off and lock out power.

3. Make sure unit is cool enough that pump can be handled

safely. Open drain to remove remaining liquid.

4. Carefully remove pump drain plug and bleed line. Wait for

complete drainage.

5. Loosen the motor bracket to pump volute capscrews.

Assure that pressure is relieved per caution note.

6. Complete the removal of the above hardware. Remove

pump/motor assembly and place on work bench.

7. Remove self locking stainless steel capscrews and stain-

less steel washer (or self locking brass cap nut and washer)

that secure the impeller in place.

8. To remove impeller from motor shaft proceed as follows:

(1) Keyed Shafts. Remove impeller with gear puller or

other means which will not damage impeller or bend

motor shaft.

(2) Threaded Shafts. Hold end of motor shaft opposite

pump with large screwdriver or other suitable tool and

back impeller with a rectangular bar or other flat tool

inserted between the vanes of the impeller.

9. Remove rotating part of seal from shaft, being careful not

to break carbon face.

10. Remove capscrews holding motor bracket to motor and

remove bracket.

11. Remove stationary part of seal assembly, being careful not

to chip or break ceramic seal.

12. To install new seal proceed as follows:

(1) Clean recess in bracket thoroughly. Coat recess and

“rubber” portion of seat with soap solution. Press seat

into recess firmly by hand making certain both parts

bottom evenly. If seal cannot be bottomed with fingers

place cardboard shipping disc on ceramic and force

into place with flat tool.

(2) Carefully place bracket in position on motor shaft with

out displacing ceramic seat and secure bracket to

motor with capscrews.

(3) Place motor vertically with pump end up. Do not

attempt assembly of seal and impeller with shaft

horizontal.

PUMP SERVICE INSTRUCTIONS FOR CENTRIFUGAL PUMPS

Vertical mounting puts motor above floor dirt and water

CAUTION / DO NOT RUN DRY. SEAL DAMAGE

MAY OCCUR: Inspect pump seal regularly for

leaks. Replace as required. Failure to follow these

instructions could result in injury or property damage.

WARNING / HIGH VOLTAGE: Disconnect and lock

out power before connecting or servicing unit.

Failure to follow these instructions could result in serious

injury or death.

CAUTION / HOT SURFACES: Surfaces are hot

when system is in operation. Do not touch hot re-

ceiver, let unit cool before servicing. Failure to follow

these instructions could result in injury or property damage.

CAUTION / PRESSURIZED SYSTEM: Operating

system may contain very hot water under pressure.

Close inlet and open drains before servicing. When ser-

vicing, loosen screws and move components to assure

pressure is relieved before removing screws. Keep drains

open during servicing. Failure to follow these instructions

could result in injury or property damage.

CAUTION / DO NOT REVERSE: Reverse operation

can cause extensive damage to pumps. Jog the

motor to test for direction of rotation. Failure to follow

these instructions could result in injury or property damage.

WARNING: EXPLOSIBLE

Do not pressurize receiver. Isolate receiver during

leak test. Do not plug overflow. Do not restrict vent opening

to atmosphere. Open valves slowly. Failure to follow these

instructions could result in serious injury or death.