Bell & Gossett DN0162F HS Vented Boiler Feed Units Series HBF and VBF User Manual

Page 6

6

These close coupled vertical centrifugal pumps are equipped

with mechanical seals. If system has not been properly

cleaned prior to installation of pump, foreign matter such as

dirt, pipe scale, core sand, etc. may clog the impeller and

damage the seal. A strainer is recommended in return line to

pump. Pump must not be operated dry. Seals may be dam-

aged if operated without water present.

1. Close inlet line gate valve and operate pump momentarily

to remove as much liquid as possible from pump. Close

discharge line gate valve.

2. Shut-off and lock-out power.

3. Disconnect wiring to motor.

4. Make sure unit is cool enough that pump can be handled

safely. Open receiver drain to remove remaining liquid.

5. Loosen the four capscrews (4) holding pump case to

motor. Assure that pressure is relieved per caution note.

6. Remove four capscrews (4) holding pump case to motor

and lift motor and impeller out of pump case.

7. Remove pump/motor assembly and place on work bench.

8. Prevent the motor shaft from turning by inserting a large

screwdriver into the screwdriver slot located under the

plug on the rear motor endbell. Back the impeller off

(counter clockwise) using a rectangular bar or other flat

tool inserted between the impeller vanes.

9. Remove the rotating part of the mechanical seal from the

end of the shaft.

10. Remove seal holder (13) with stationary ceramic part of

mechanical seal and cup rubber from the end of the shaft.

11. Remove stationary ceramic part of mechanical seal and

cup rubber from recess in seal holder.

12. To install new seal, proceed as follows: Clean recess in

seal holder thoroughly. Insert new ceramic seat (grooved

face first) into the rubber seat cup. Lubricate the outside of

the cup and seal holder recess with soapy water. Install

the ceramic/cup assembly into the seal holder, making

sure the assembly bottoms evenly. When repairing "B"

style pumps manufactured between 1983 through 2001,

orient wire spacer eye to the left midway between motor

lugs. Replace seal holder over wire spacer on the face of

the motor, maintaining concentricity with motor face.

Pumps manufactured in 2002 or later, are manufactured

with DP1966 seal holder and do not require the wire

spacer. Pumps using DP1966 should orient the seal holder

tab to the left, midway between motor lugs. Using a clean,

lint-free cloth, wipe the mating surfaces of the seal clean

of any foreign matter. Moisten the carbon section of the

rotating part of the seal and lubricate the I.D. with soapy

water. Place onto shaft to seat against the ceramic.

13. Hold motor shaft as described in #8 and replace the im-

peller on the shaft (clockwise rotation) making sure it is tight.

14. Orient motor for pump reassembly with conduit opening to

the left. When mounting the pump case, discharge should

be 90˚ to the right of the wire spacer eye or (90˚ to the tabs

on DP1966) and conduit opening on motor. Use care to

insure tight gasket fit to prevent water leakage. When

replacing pump case, the wire spacer eye or the tabs on

DP1966 should seat in pump case notch. If this does not

occur inspect for proper alignment and reassemble.

15. Replace four capscrews (4). Tighten down capscrews

evenly to avoid damage.

16. Reconnect pump bleed line (where applicable) and motor

wiring.

PUMP SERVICE INSTRUCTIONS FOR WATCHMAN CENTRIFUGAL PUMPS

WARNING / HIGH VOLTAGE: Disconnect and lock

out power before connecting or servicing unit.

Failure to follow these instructions could result in serious

injury or death.

CAUTION / HOT SURFACES: Surfaces are hot

when system is in operation. Do not touch hot re-

ceiver, let unit cool before servicing. Failure to follow

these instructions could result in injury or property damage.

CAUTION / PRESSURIZED SYSTEM: Operating

system may contain very hot water under pressure.

Close inlet and open drains before servicing. When ser-

vicing, loosen screws and move components to assure

pressure is relieved before removing screws. Keep drains

open during servicing. Failure to follow these instructions

could result in injury or property damage.

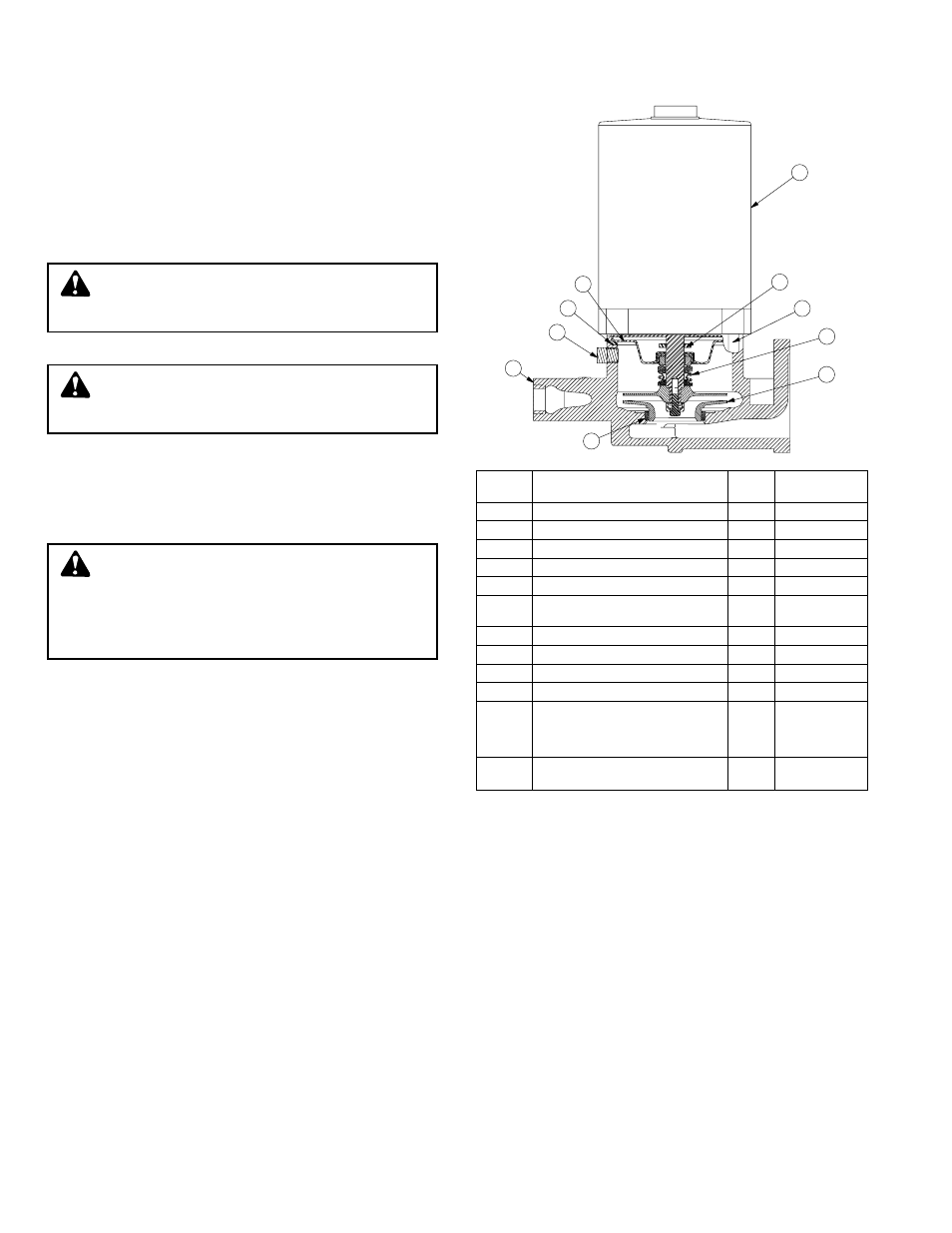

1

10

7

3

4

8

6

9

5

2

Item

No.

Part

Number

Description

Req'd.

No.

1

Motor

1

/

3

hp, 1 ph. 3500 rpm

1

180096

2

Seal Holder

1

DP1966

3

Seal*

1

—

4

Impeller

1

DP0321

5

Head Gasket*

1

DG0092

6

Pump Case with

wearing ring

1

DP1665

7

Capscrew

1

DJ0083

8

Wear Ring

1

DP0482

9

Pipe Plug

1

/

4

" (6 mm)

1

P39040

10

Water Slinger

1

DP0848

Seal kit including

mechanical seal, head

*

gasket, & case to

receiver gasket

1

180013

Complete pump and

motor assembly

1

180001

Order Replacement Parts by Description and Part No.

Specify Serial No. shown on nameplate.