Bell & Gossett DN0137D Domestic Pump Vacuum & Boiler Feed Unit Series VCMD User Manual

Page 9

9

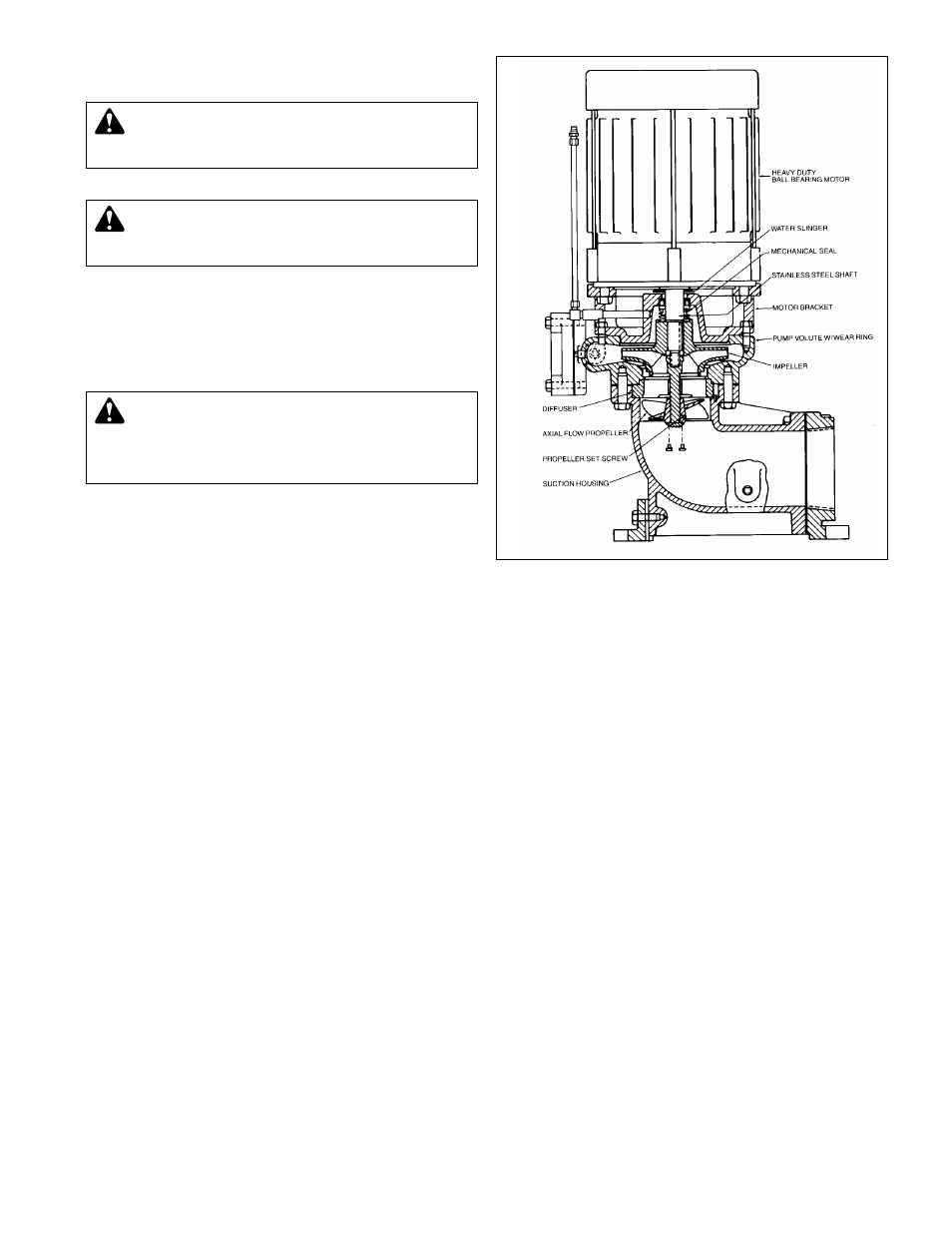

1. Close pump isolation valve or system return line valve. Operate

pump momentarily to discharge as much water as possible. Close

pump discharge valve.

2. Shut-off and lock out power.

3. Make sure unit is cool enough that pump can be handled safely.

Open drain to remove remaining liquid.

4. Carefully remove pump drain plug and bleed line. Wait for com-

plete drainage.

5. Loosen both the discharge connection and the suction housing to

pump volute fasteners. Assure that the pressure is relieved per

caution note.

6. Complete the removal of the hardware. Remove pump/motor

assembly and place on work bench.

7a. Remove the suction housing capscrews and separate the

pump/motor assembly from the suction housing. Note, the dif-

fuser should separate from the suction housing to allow the

pump/motor assembly to be removed.

(1) Threaded Motor Shafts (3Hp and less). Remove propeller lock

nut. Remove propeller with propeller stem as an assembly with

the diffuser. To install a new propeller, remove the propeller set

screws and separate from the stem.

(2) Keyed Motor Shafts (5Hp and larger). Remove propeller set

screws. Remove propeller, remove diffuser, and unscrew the

propeller stem.

7b. Remove propeller, propeller stem and diffuser from the assembly

as follows:

8. Remove capscrews holding motor bracket and pump volute

together. Remove motor and bracket assembly from the volute by

lifting straight away from volute.

9. To remove impeller from motor shaft proceed as follows:

(1) Keyed Shafts. Remove impeller with gear puller or other means

which will not damage impeller or bend motor shaft.

(2) Threaded Shafts. Hold end of motor shaft opposite pump with

large screwdriver or other suitable tool and back impeller off

with a rectangular bar or other flat tool inserted between the

vanes of the impeller.

10. Remove rotating part of seal from shaft, being careful not break

carbon face.

11. Remove capscrews holding motor bracket to motor and remove

bracket.

12. Remove stationary part of seal assembly, being careful not to chip

or break ceramic seal.

13. To install seal proceed as follows:

(1) Clean recess in bracket thoroughly. Coat recess and “rubber”

portion of seat with soap solution. Press seat into recess

firmly by hand making certain both parts bottom evenly. If seal

cannot be bottomed with fingers place cardboard shipping

disc on ceramic and force into place with flat tool.

(2) Carefully place bracket in position on motor shaft without

displacing ceramic seat and secure bracket to motor with

capscrews.

(3) Place motor vertically with pump end up. Do not attempt

assembly of seal and impeller with shaft horizontal.

(4) The “carbon” of rotating part of seal should not be loose. If it

is, hold in place with grease, Using clean, lint free cloth, wipe

mating surfaces perfectly clean. Soap shaft and push seal onto

shaft so that carbon will contact ceramic seal. If spacer is

required, use grease to cause spacer to adhere to bottom of

seal after seal has been put on shaft, Be sure spacer is on

larger diameter of shaft so that will not catch between shoulder

and impeller.

14. Place impeller on shaft. Make sure impeller is seated.

15. Reassemble volute to bracket.

16. Install stem over drive pin in impeller eye. Tighten lock nut.

17. Set stem to .004 TIR.

CAUTION:

PRESSURIZED SYSTEM

Operating system may contain very hot water

. Close inlet

and open drains before servicing. When servicing,

loosen scr

ews

and move components to assure pressure is relieved before

r

emov-

ing

scr

ews. Keep drains open during servicing. Failure to follow

these instructions could result in injury or death.

CAUTION:

HOT SURFACE

Surfaces ar

e hot when system is in operation. Do not touch

hot receiver, let unit cool before servicing. Failure to follow these

instructions could result in serious injury or death.

W

ARNING: HIGH VOLTAGE

Disconnect and lock out power befor

e connecting servicing

unit. Failure to follow these instructions could result in serious injury

or death.