Putting the unit into ser vice, Over view – Bell & Gossett DN0137D Domestic Pump Vacuum & Boiler Feed Unit Series VCMD User Manual

Page 4

PUTTING THE UNIT INTO SER

VICE

1.

Assure that the unit is piped in accordance with instructions.

2. Isolate tank before performing any system leak test. Do not pres-

surize the tank as part of the leak test. Failure to do this can result

in serious injury or death.

3. Check floats for free operation. Assure that shipping locks have

been removed.

4. Check power leads in accordance with wiring diagram enclosed in

control cabinet (when furnished).

5. Install drain plugs.

6. Fill receiver (upper compartment on Series VLR) half full of water to

prime pump(s) and prevent possible damage to pump seals. Avoid

freezing conditions after unit receiver has been filled.

7. Check for proper rotation of all three phase motors. Rotation must

be clockwise looking down on the motor as indicated by direc-

tional arrow on pump casting. If pump runs backwards, inter-

change two wires (3 phase only).

8. Throttle plug cock in discharge line until pressure at pump (while

pump is discharging) approaches pump rated pressure. Tighten

plug nut to secure adjustment.

9. Connect the water make-up assemblies to city water. Use piping at

least as large as the valve piping provided. Provide a manual fill

valve if not included on the unit. Vacuum producer and boiler feed

unit have separate make-ups.

10. Vacuum switches are factory set per job specifications and re-

adjustment should not be necessary. Refer to switch manufac-

turer’s literature for details of adjusting procedure. If resetting is

required, it is helpful to disconnect wiring and set one switch at a

time. The “lead” switch must make and break at a slightly deeper

vacuum than the “lag” switch.

Typical vacuum switch settings are as follows:

Switch

Make

Break

LEAD

3"

8"

LAG

2

1

/

2

"

8"

11. Assure that the controls on and related to the boiler match the con-

trol systems provided on the unit (see the wiring diagram furnished)

(applicable when electrical control panel is furnished).

W

ARNING: MAINTAIN BOILER SAFETY FEATURES

When connecting the boiler feed unit to the boiler

, assure

that all boiler safety controls (burner cutoff, etc.) are and remain

operational. With certain control arrangements, dedicated boiler

controllers are required for the boiler feed pumps. Failure to follow

these instructions could result in serious injury, death or extensive

property damage.

W

ARNING: EXPLOSIBLE

Do not pr

essurize receiver. Isolate receiver during leak test.

Do not plug overflow. Do not restrict vent opening to atmosphere.

Open valves slowly. Failure to follow these instructions could result

in serious injury or death.

4

W

ARNING: HIGH VOLTAGE

Disconnect and lock out power befor

e connecting or servic-

ing unit. Failure to follow these instructions could result in serious

injury or death.

CAUTION:

DO NOT REVERSE

Reverse operation can cause extensive damage to pumps.

Jog the motor to test for direction of rotation. Failure to follow these

instructions could result in injury or property damage.

OVER

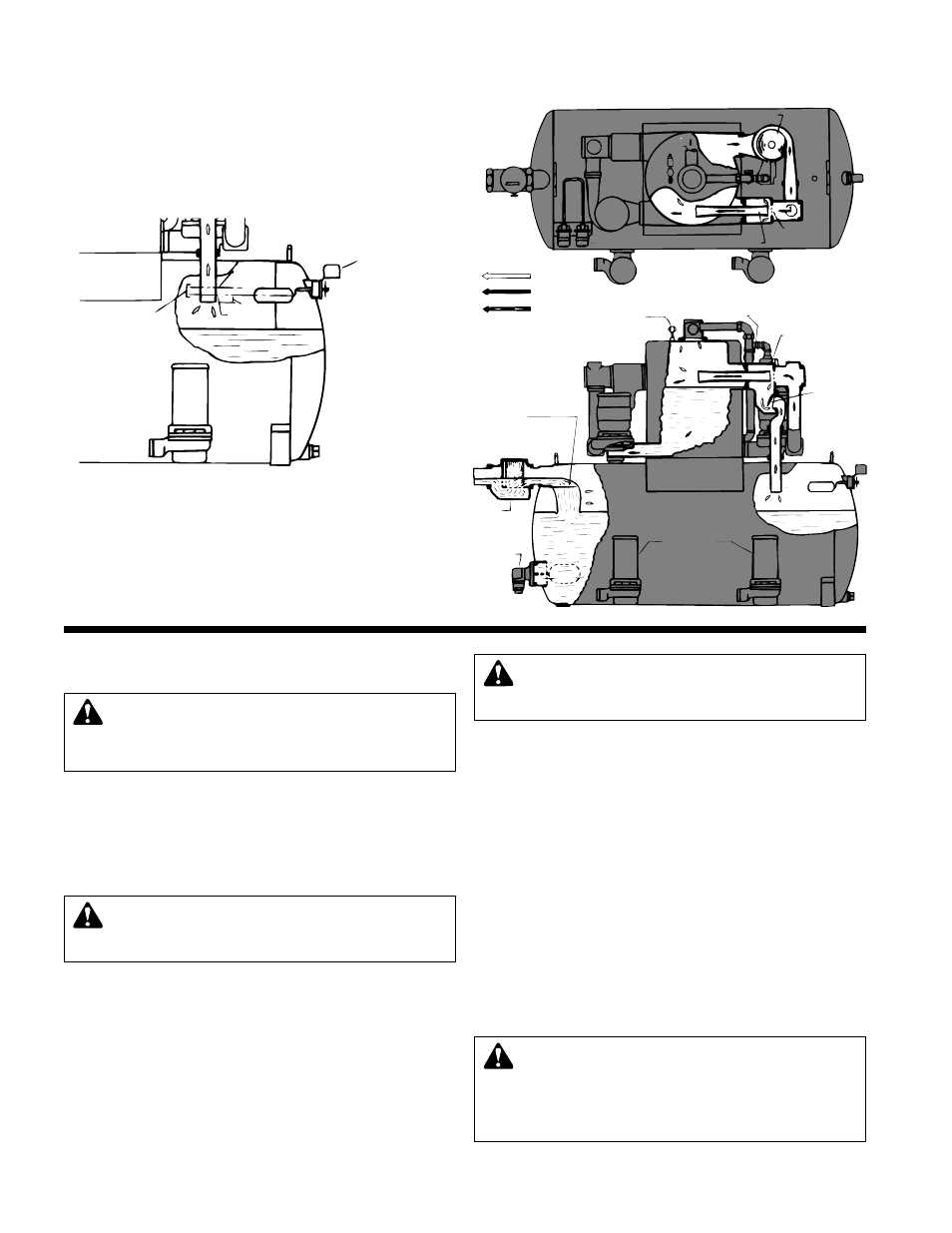

VIEW

SIMPLE AUTOMATIC OVERFLOW CONTROL

If excess condensate enters the boiler feed r

eceiver, the water level will

rise above a preselected height, and float switch will actuate the air

pump. The resulting vacuum draws excess water through the air suc-

tion line into the separation chamber of the air pump from where it sim-

ply overflows to a drain. An overflow pump is not necessary or recom-

mended unless the drain is located above the overflow of the air pump.

If such a drain exists, an overflow pump can be furnished. The float

switch will then start the overflow pump instead of the air pump.

FIG. 5 ADJUSTMENT OF OVERFLOW CONTROL FLOA

T SWITCH

1.

Close inlet valve. Set all selector switches to “Off”.

2. Add water to condensate receiver until it is flooded.

3. Operate air pump to bring water level to bottom of air suction (lift)

pipe; turn selector switch(es) to “Off”.

4. Adjust float switch to open about

1

/

2

" above this level.

5. Set the other quadrant as close as possible for minimum differential.

OVERFLOW

SWITCH

CONTACTS

CLOSE

1/2"

CONTACTS

OPEN

ADJUST SWITCH

FOR MINIMUM

DIFFERENTIAL

AIR

VENT

VACUUM PUMP IMPELLER

MULTI-JET

NOZZLE

VENTURI

VACUUM SWITCHES

AIR

WATER

AIR & WATER

VACUUM PUMP

SOLENOID VALVE FOR

HURLING WATER

CONTROL

OVERFLOW (GRAVITY)

FLOAT SWITCH FOR

HURLING WATER

CONTROL

AIR SUCTION

CHECK VALVE

DEAERATING CASCADE

BAFFLE

HURLING

WATER

AIR

SUCTION

AND OVERFLOW

CONDENSATE

BOILDER FEED RECEIVER

BOILER FEED

PUMPS

INLET

STRAINER

(OPTIONAL)

MECHANICAL

WATER MAKE

UP VALVE